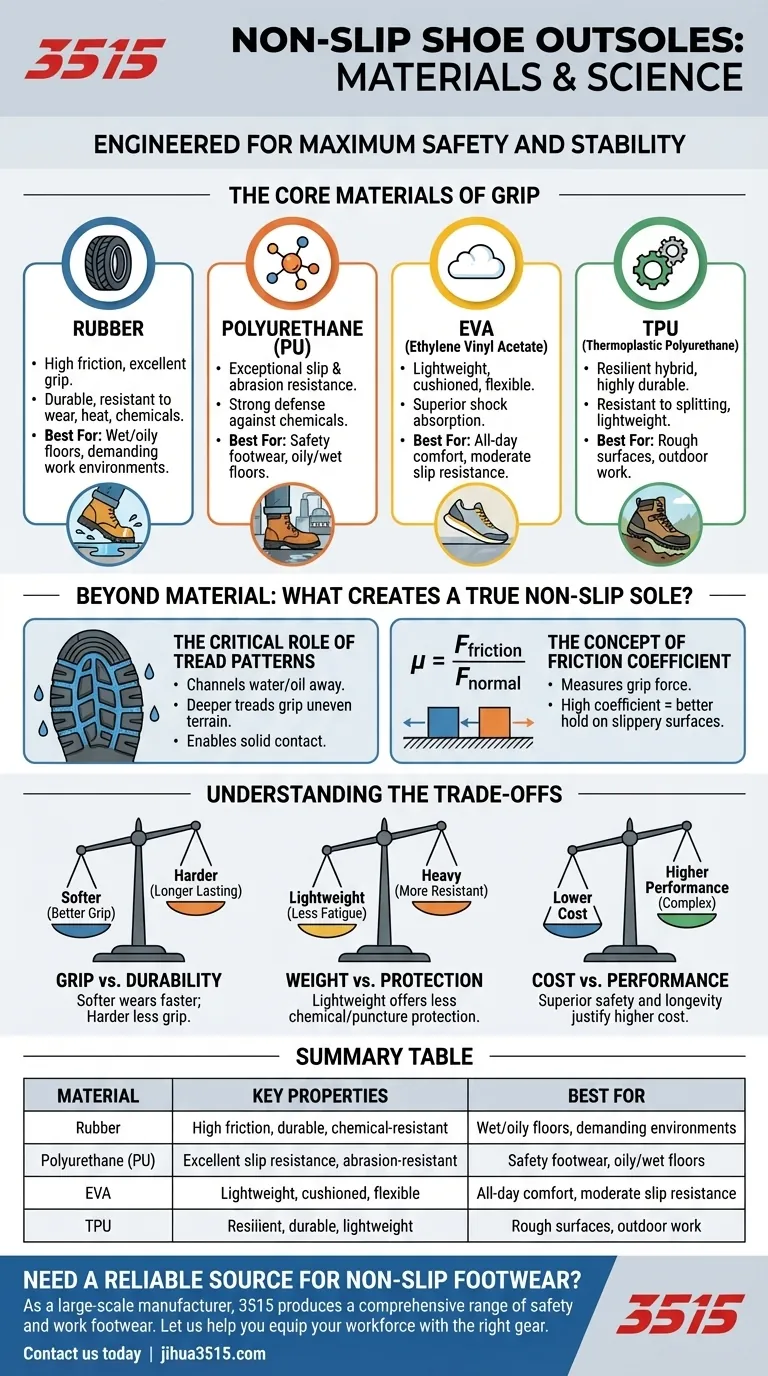

To ensure maximum safety and stability, non-slip shoe outsoles are engineered from specific high-friction materials. The most common choices are Rubber, Polyurethane (PU), EVA (Ethylene Vinyl Acetate), and TPU (Thermoplastic Polyurethane), each selected for a unique balance of grip, durability, and flexibility required for the intended environment.

The effectiveness of a non-slip shoe is not determined by a single "best" material. Instead, it's a calculated engineering choice, balancing a material's inherent grip with its durability and the design of its tread pattern to conquer specific slippery surfaces.

The Core Materials of Grip

The outsole is the critical point of contact between you and the ground. The material used here dictates how the shoe will perform under pressure, especially on hazardous surfaces.

Rubber: The Industry Standard

Rubber is the most widely used material for non-slip outsoles due to its naturally high coefficient of friction. This property gives it an excellent grip on most surfaces.

It is highly valued for its resistance to wear, heat, acids, and alkalis, making it a reliable choice for demanding work environments. Different formulations exist, such as carbon-infused black rubber for durability or softer gum rubber for enhanced flexibility and grip.

Polyurethane (PU): The Durable Performer

Polyurethane is a versatile polymer known for its exceptional slip resistance and durability. It provides a strong defense against abrasion and common workplace chemicals.

PU outsoles are often found on safety and work footwear where longevity and consistent performance on oily or wet floors are non-negotiable.

EVA (Ethylene Vinyl Acetate): The Lightweight Cushion

EVA is a foam-like material celebrated for its incredible lightness, flexibility, and superior shock absorption. This makes it extremely comfortable for long periods of standing or walking.

While pure EVA can be less grippy than rubber, it is often used in combination with rubber or TPU pods placed in high-wear areas to provide both comfort and targeted traction.

TPU (Thermoplastic Polyurethane): The Resilient Hybrid

TPU is a more modern material that acts as a bridge between the softness of rubber and the rigidity of plastic. It is lightweight, highly durable, and has excellent resistance to splitting or cracking.

This material offers a fantastic balance of properties, providing reliable grip and abrasion resistance without the weight of traditional rubber.

Beyond the Material: What Creates a True Non-Slip Sole?

The raw material is only half of the equation. A shoe's ability to prevent slips is also heavily influenced by its physical design and how it interacts with surfaces.

The Critical Role of Tread Patterns

Think of a shoe's outsole like a car tire. The tread pattern is designed to channel water, oil, and other contaminants away from the point of contact.

Deeper, more intricate treads with sharp edges are better suited for gripping uneven terrain or displacing liquids, ensuring the sole material makes solid contact with the ground.

The Concept of Friction Coefficient

At a technical level, grip is measured by the coefficient of friction. This value represents how much force is needed to move one surface over another.

Non-slip outsole materials are engineered to have a high coefficient of friction against common flooring surfaces like tile, concrete, and linoleum, especially when they are wet or oily.

Understanding the Trade-offs

Choosing the right outsole material always involves balancing competing priorities. There is no single material that excels at everything.

Grip vs. Durability

A softer rubber compound will offer superior grip because it can conform better to microscopic imperfections in a surface. However, this softness often means it will wear down more quickly.

Conversely, a harder, denser material will last longer but may sacrifice some of its gripping power, especially on very smooth surfaces.

Weight vs. Protection

Lightweight materials like EVA significantly reduce foot fatigue over a long day. The trade-off is that they may not offer the same level of resistance to heat, chemicals, or punctures as a thick rubber outsole.

Cost vs. Performance

High-performance materials like specialized rubber compounds or TPU are more complex and expensive to manufacture. This cost is reflected in the final price of the shoe but is often justified by superior safety and longevity.

Making the Right Choice for Your Environment

Your specific needs should guide your selection. Consider where and how you will be using the footwear.

- If your primary focus is maximum safety in wet or oily areas (e.g., professional kitchens, garages): Prioritize shoes with rubber or PU outsoles that feature deep, channel-like tread patterns.

- If your primary focus is all-day comfort with moderate slip resistance (e.g., healthcare, retail): Look for hybrid outsoles that combine a cushioning EVA midsole with strategically placed rubber or TPU pods for grip.

- If your primary focus is durability on rough surfaces (e.g., construction, outdoor work): Choose a dense rubber or TPU outsole known for high abrasion and wear resistance.

Ultimately, understanding the science behind the sole empowers you to select the right tool for the job, ensuring both safety and performance.

Summary Table:

| Material | Key Properties | Best For |

|---|---|---|

| Rubber | High friction, durable, chemical-resistant | Wet/oily floors, demanding work environments |

| Polyurethane (PU) | Excellent slip resistance, abrasion-resistant | Safety footwear, oily/wet floors |

| EVA | Lightweight, cushioned, flexible | All-day comfort, moderate slip resistance |

| TPU | Resilient, durable, lightweight | Rough surfaces, outdoor work |

Need a reliable source for non-slip footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety and work footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, engineered with the right materials and tread patterns for maximum safety and durability in your specific environment.

Let us help you equip your workforce with the right gear. Contact us today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job