At their core, safety clogs are specialized slip-on shoes designed for professional environments where hygiene, all-day comfort, and slip resistance are the most critical priorities. They are purpose-built for industries like healthcare, food processing, and laboratories, where floors are frequently wet and the footwear itself must be easy to clean and disinfect.

The term "safety" in safety clogs primarily refers to protection from slips and falls on hazardous surfaces, not from impact or puncture wounds. They trade heavy-duty protection for superior hygiene and ergonomic comfort.

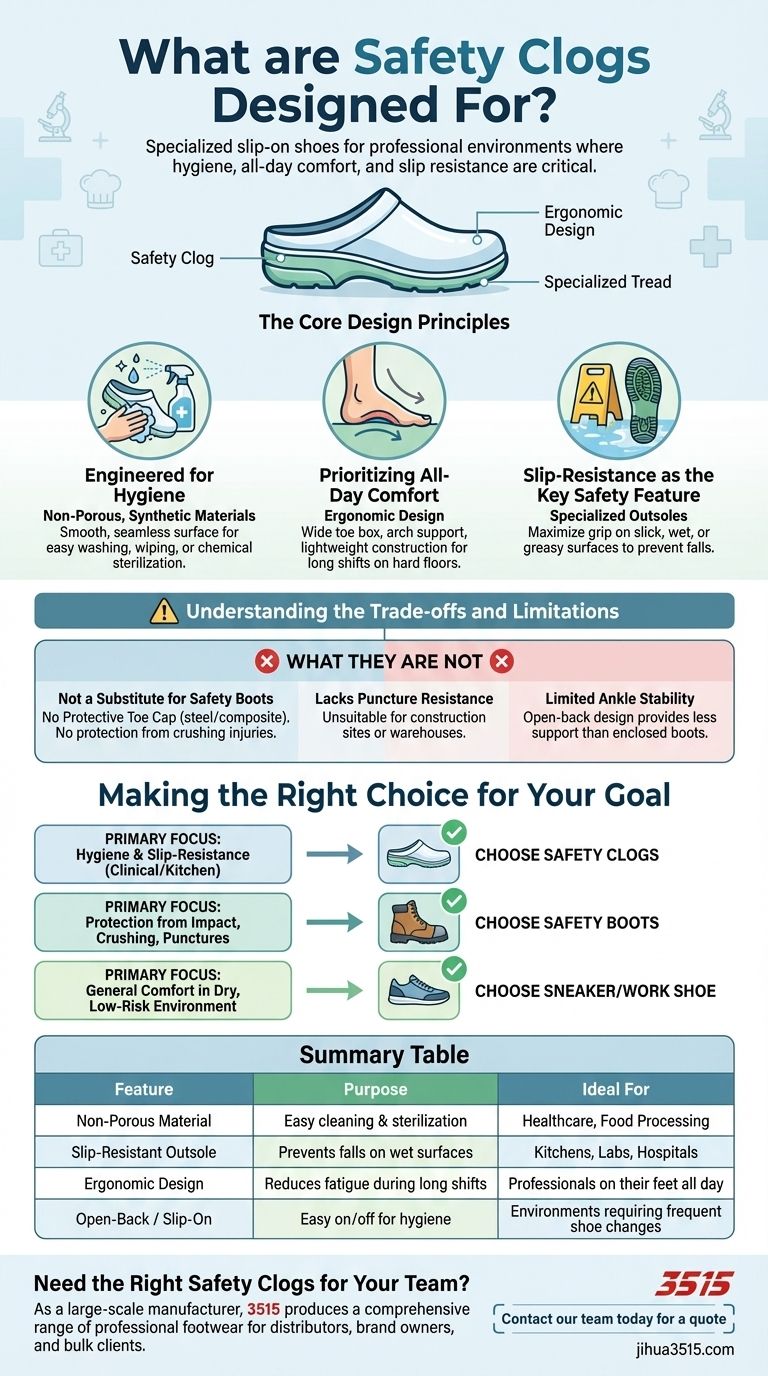

The Core Design Principles of Safety Clogs

To understand their purpose, it's essential to look at the specific problems they are designed to solve. The design of a safety clog is a direct response to the daily challenges faced by professionals in sterile or service-oriented environments.

Engineered for Hygiene

Safety clogs are almost always constructed from non-porous, synthetic materials like rubber or specialized polymers.

This material choice is deliberate. It creates a smooth, seamless surface without laces, mesh, or deep stitching where bacteria, fluids, or contaminants can accumulate. This makes them exceptionally easy to wash, wipe down, or chemically sterilize between shifts.

Prioritizing All-Day Comfort

Professionals in healthcare and food service spend extremely long hours on their feet, often on hard tile floors.

Safety clogs address this with an ergonomic design. They typically feature a wide toe box to prevent constriction, significant arch support, and lightweight construction to reduce fatigue over a 12-hour shift.

Slip-Resistance as the Key Safety Feature

The primary hazard in a hospital ward or commercial kitchen is often a wet or greasy floor, not a falling object.

The outsoles of safety clogs are engineered with specialized tread patterns to maximize grip on these slick surfaces. This focus on preventing slips and falls is the main "safety" component for this category of footwear.

Understanding the Trade-offs and Limitations

It is critical to distinguish what safety clogs are not. Misunderstanding their purpose can lead to significant workplace injuries. Their specialized design inherently involves trade-offs.

Not a Substitute for Safety Boots

A standard safety clog does not have a protective toe cap (like a steel or composite toe). It offers no protection against crushing injuries from heavy falling objects.

They also lack a puncture-resistant sole, making them unsuitable for environments like construction sites or warehouses where sharp objects on the ground are a risk.

The Open-Back Design

The classic clog design is open at the heel, which allows for easy slip-on and slip-off functionality.

However, this provides less ankle stability and support than a fully enclosed shoe or boot. While many models now include a pivoting heel strap for a more secure fit, they are not designed for running or rapid, uneven movements.

Making the Right Choice for Your Goal

Selecting the correct footwear is about matching the tool to the specific hazards of your environment.

- If your primary focus is hygiene and slip-resistance in a clinical or kitchen setting: A safety clog is precisely engineered for your needs.

- If your primary focus is protection from impact, crushing, or punctures: You must choose a certified safety boot or shoe with a protective toe and midsole.

- If your primary focus is general comfort for standing but in a dry, low-risk environment: A supportive sneaker or standard work shoe may be a more appropriate choice.

Ultimately, choosing the right footwear begins with an honest assessment of your workplace risks.

Summary Table:

| Feature | Purpose | Ideal For |

|---|---|---|

| Non-Porous Material | Easy cleaning & sterilization | Healthcare, Food Processing |

| Slip-Resistant Outsole | Prevents falls on wet surfaces | Kitchens, Labs, Hospitals |

| Ergonomic Design | Reduces fatigue during long shifts | Professionals on their feet all day |

| Open-Back / Slip-On | Easy on/off for hygiene | Environments requiring frequent shoe changes |

Need the Right Safety Clogs for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of professional footwear for distributors, brand owners, and bulk clients. Whether you need reliable safety clogs for a hospital, food processing plant, or laboratory, we have the production capabilities and expertise to meet your needs.

Let us help you equip your workforce with footwear that prioritizes safety and comfort.

Contact our team today for a quote to discuss your specific requirements.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What is the benefit of deeper grooves in slip-resistant shoe soles? Maximize Traction & Safety

- Why are slip-resistant shoes important in certain work environments? An Expert's Guide to Workplace Safety

- How do lightweight work shoes lessen impact and reduce fatigue? Boost Performance and Comfort

- What advantages do specialized work shoes offer? Enhance Safety and Health in High-Risk Industrial Sectors

- How do non-slip soles in chef shoes enhance safety? Unlock the Engineering Behind Kitchen Grip

- What materials are typically used in non-slip shoe outsoles? The Science of Slip-Resistant Footwear

- What industries require non-slip shoes? Protect Your Workforce in High-Risk Environments

- How do slip resistant shoes contribute to day-to-day comfort and long-term foot health? Beyond Safety, a Foundation for Well-being