In practice, there is no functional difference between "anti-slip" and "non-slip"; they are both used to market products designed to prevent slips. However, the most technically accurate and trustworthy term is slip-resistant. This term acknowledges that no material can completely eliminate the risk of slipping under all conditions.

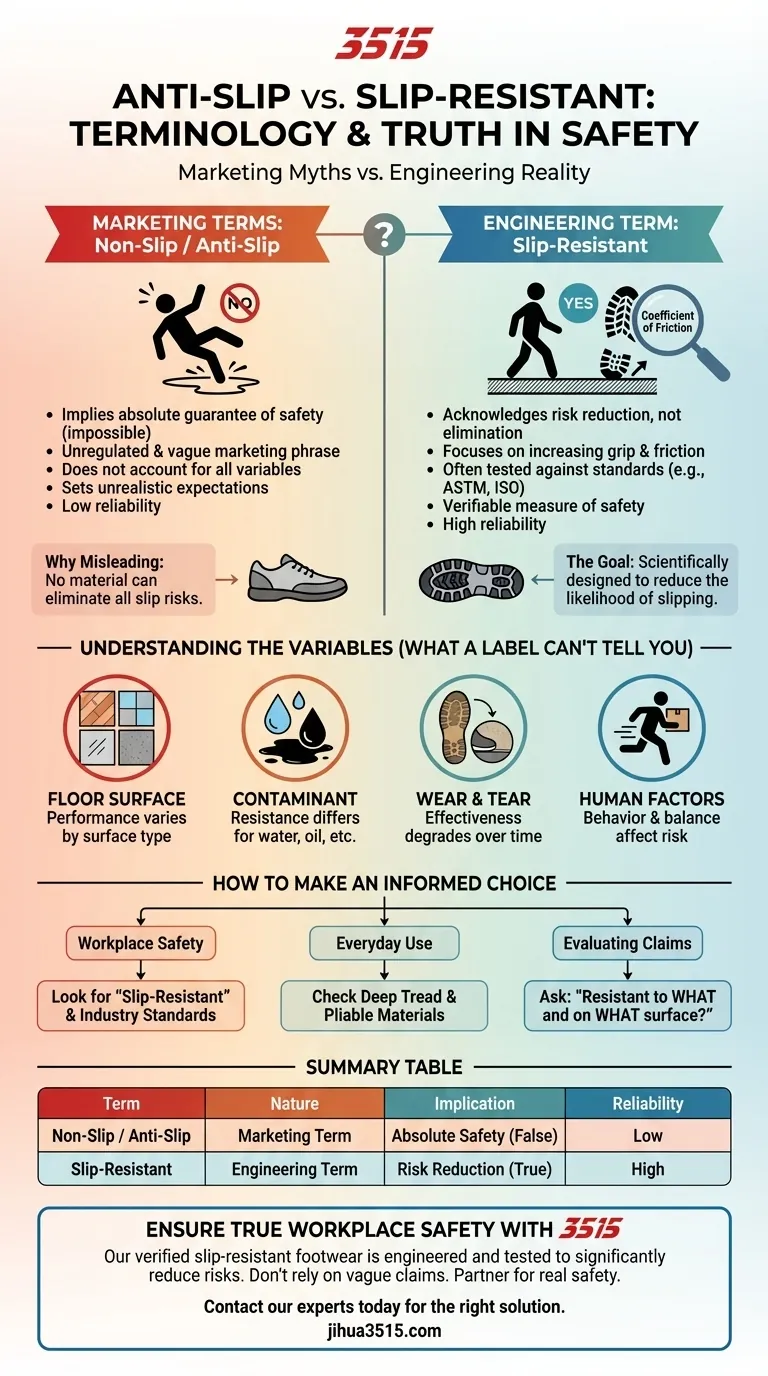

The core issue is one of marketing versus engineering. "Non-slip" and "anti-slip" are marketing terms that imply an absolute guarantee of safety, which is impossible. "Slip-resistant" is an engineering term that accurately describes a material designed and tested to reduce the likelihood of slipping on hazardous surfaces.

Why "Non-Slip" Is a Misleading Term

Many products, from shoes to floor treatments, are labeled as "non-slip." While the intent is to convey safety, the term itself sets an unrealistic expectation that can be dangerous.

The Problem of Absolutes

The term non-slip suggests a complete prevention of slips. This is a physical impossibility.

Variables like the type of floor, the presence of contaminants (water, oil, dust), and even the way a person walks can cause a slip, regardless of their footwear. No product can control for all these factors.

A Marketing Claim, Not a Standard

"Non-slip" and "anti-slip" are not regulated technical specifications. They are marketing phrases used to attract consumers looking for a simple solution to a complex problem.

Because these terms lack a standardized definition, they don't tell you how effective the product is or under what conditions it was tested.

"Slip-Resistant": The Engineering Reality

In professional and industrial contexts, the term slip-resistant is preferred. It reflects a more honest and scientific approach to safety.

A Focus on Risk Reduction

The goal of a slip-resistant product is not to eliminate risk but to significantly reduce it.

These products are engineered with specific materials and tread patterns designed to increase the coefficient of friction—the gripping force between two surfaces.

The Role of Standardized Testing

True slip-resistant footwear and flooring are often tested against recognized safety standards.

These tests measure performance in specific, controlled conditions (e.g., on a wet ceramic tile or oily steel surface) and provide a rating. This offers a verifiable measure of safety, unlike the vague promise of "non-slip."

Understanding the Trade-offs: What a Label Can't Tell You

Even the best slip-resistant product has limitations. True safety comes from understanding the variables that a simple label can't account for.

The Floor Surface

A shoe that is highly resistant on a wet quarry tile floor might perform poorly on a greasy, polished concrete surface. The interaction between the shoe and the floor is critical.

The Contaminant

Resistance to water does not guarantee resistance to oil. Different contaminants have different viscosities and properties that dramatically alter the friction between surfaces.

Wear and Tear

The effectiveness of a slip-resistant sole or floor coating degrades over time. As the tread pattern wears down or the surface texture smooths out, its ability to channel away liquids and maintain grip diminishes.

Human Factors

How a person walks, their speed, their balance, and whether they are carrying heavy objects all contribute to slip risk. No product can ever fully compensate for human behavior.

How to Make an Informed Choice

Choosing the right product requires looking past simple marketing claims and focusing on your specific environment and needs.

- If your primary focus is workplace safety: Ignore generic "non-slip" claims. Look for products explicitly labeled "slip-resistant" and check if they meet specific industry safety ratings (like ASTM or ISO standards).

- If your primary focus is everyday use: Understand that "non-slip" is just a feature. Examine the shoe's sole for deep, multi-directional tread patterns and soft, pliable materials that offer better grip.

- If your primary focus is evaluating any claim: Always ask, "Resistant to what, and on what surface?" A product's true value depends entirely on the context of its use.

Focusing on verified resistance, not impossible promises, is the key to making a truly safe choice.

Summary Table:

| Term | Nature | Implication | Reliability |

|---|---|---|---|

| Non-Slip / Anti-Slip | Marketing Term | Implies absolute safety | Low (unregulated, vague) |

| Slip-Resistant | Engineering Term | Acknowledges risk reduction | High (tested, verifiable) |

Ensure True Workplace Safety with 3515's Slip-Resistant Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of verified slip-resistant footwear for distributors, brand owners, and bulk clients. Our products are engineered with specific materials and tread patterns, designed and tested to significantly reduce slip risks in various hazardous conditions—from wet tiles to oily surfaces.

Don't rely on vague marketing claims. Partner with 3515 for footwear backed by engineering principles and a commitment to real safety.

Contact our experts today to discuss your specific needs and find the right slip-resistant solution for your business.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

People Also Ask

- What materials are used in slip resistant soles? Choose the Right Sole for Safety & Performance

- What is the primary role of anti-slip safety shoes in palm oil mill boiler stations? Ensure Worker Safety & Stability

- What additional contaminants might some brands test for beyond ASTM standards? Grease Testing for Ultimate Slip Resistance

- Why are slip-resistant shoes important in kitchen or restaurant environments? Prevent Slips and Falls

- Why is a high-performance anti-slip outsole essential for single-leg exoskeleton users? Ensure Stability and Safety

- How can slip-resistant shoes help prevent workplace accidents? Essential Safety for High-Risk Environments

- What is a recommended alternative to using hairspray for slip resistance? Ditch Unreliable Hacks for Real Safety

- Why is a lightweight design important for chef shoes? Boost Endurance and Agility in the Kitchen