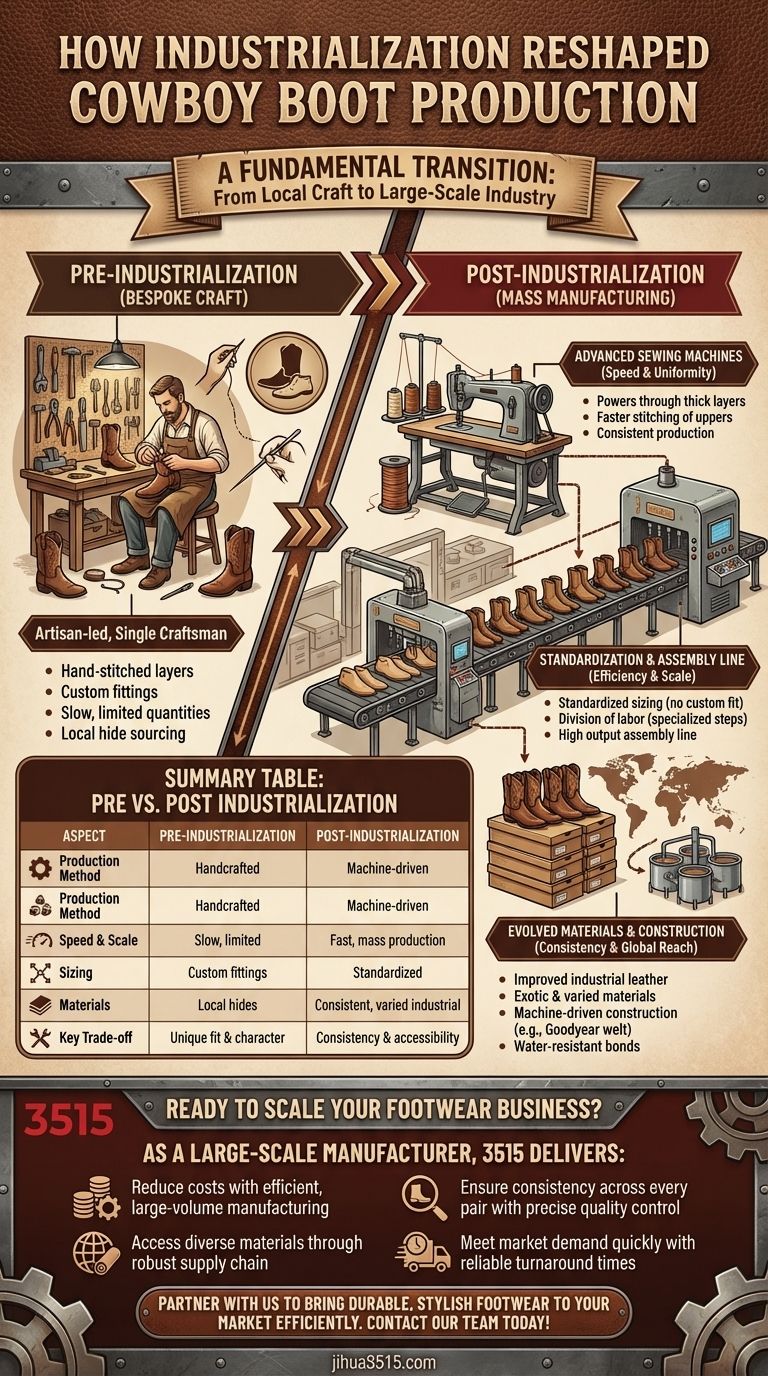

Industrialization fundamentally reshaped cowboy boot production, transforming it from a localized craft into a large-scale manufacturing industry. The introduction of advanced sewing machines capable of handling thick leather and the availability of improved materials were the primary drivers. This shift allowed for significantly faster and more consistent production, making cowboy boots available in much larger quantities than ever before.

The core change was not simply about making more boots; it was a fundamental transition from a bespoke, manual process to a standardized, machine-driven one. This democratization of the cowboy boot introduced a new balance between scale, cost, and craftsmanship.

The Core Technological Shift: From Hand to Machine

Before industrialization, a single craftsman was responsible for nearly every step of a boot's creation, a time-consuming and expensive process. Mechanization introduced efficiency and consistency that were previously impossible to achieve.

The Impact of Advanced Sewing Machines

Heavy-duty sewing machines were the cornerstone of this revolution. These machines could power through multiple layers of tough leather with a speed and uniformity that no human hand could match.

This mechanization drastically reduced the time required to stitch the boot's upper sections (the shaft and vamp), which is one of the most labor-intensive parts of the process.

Standardization of Sizing and Lasts

True mass production requires standardization. Factories introduced standardized sizing based on "lasts"—the foot-shaped forms that boots are built around.

This shift meant a customer no longer needed a custom fitting. They could simply choose a standard size, allowing for the production of inventory and the rise of retail stores selling ready-to-wear boots.

The Assembly Line Approach

Industrialization brought the concept of the division of labor to bootmaking. Instead of one artisan building a complete boot, the process was broken down into dozens of specialized steps.

One worker would cut the leather, another would stitch the uppers, a third would attach the sole, and so on. This assembly-line model dramatically increased the output and efficiency of a single factory.

Evolution in Materials and Construction

The changes weren't limited to just the machinery; the materials used and how they were sourced also evolved significantly, directly impacting the final product.

Improved Tanning and Leather Sourcing

Industrial-scale tanneries produced more consistent and durable leather. Furthermore, improved logistics and transportation meant that bootmakers were no longer limited to locally sourced hides.

This opened the door to using more exotic and varied leathers, contributing to the boot's evolution as a fashion item.

New Construction Methods

While traditional methods like the pegged lemonwood shank construction continued, new and faster methods for attaching soles, like welt stitching done by machine, became commonplace.

These methods, like the Goodyear welt, offered a strong and water-resistant bond that could be executed with high speed and precision by machinery.

Understanding the Trade-offs

The transition to industrialized production was not without its compromises. Understanding these trade-offs is key to appreciating the differences between a factory-made and a bench-made boot.

Scale vs. Customization

The most significant trade-off is volume versus individual fit. Factory production excels at creating thousands of identical, high-quality boots at an accessible price point.

However, it loses the nuance of a custom boot built specifically for the unique contours of an individual's foot.

Consistency vs. Handcrafted Character

Machine stitching is perfectly even and consistent, which is a hallmark of quality manufacturing.

A handmade boot, by contrast, may have minute imperfections that impart a unique character and tell the story of its creation. Neither is inherently superior, but they serve different values.

Making the Right Choice for Your Goal

This history directly informs the boots available on the market today. Knowing the difference in production methods allows you to select a boot that aligns perfectly with your needs.

- If your primary focus is a perfect fit and unique artistry: Seek out custom or bench-made boots where traditional, manual techniques remain central to the process.

- If your primary focus is accessibility and value: Modern, factory-produced boots leverage industrial efficiencies to offer excellent durability and style for the price.

- If your primary focus is a blend of quality and consistency: Look for brands that combine efficient mechanized production for the main construction with skilled hand-finishing for critical details.

By understanding how a boot is made, you are empowered to choose the one that truly fits your purpose.

Summary Table:

| Aspect | Pre-Industrialization | Post-Industrialization |

|---|---|---|

| Production Method | Handcrafted by a single artisan | Machine-driven, assembly line |

| Speed & Scale | Slow, limited quantities | Fast, mass production |

| Sizing | Custom fittings | Standardized sizing |

| Materials | Local hides | Consistent, varied leathers from industrial tanneries |

| Key Trade-off | Unique fit and character | Consistency and accessibility |

Ready to Scale Your Footwear Business with Industrial-Grade Production?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, leveraging advanced machinery and standardized processes to deliver high-quality, consistent products at scale—just as industrialization revolutionized cowboy boot production.

We help you:

- Reduce costs with efficient, large-volume manufacturing

- Ensure consistency across every pair with precise quality control

- Access diverse materials through our robust supply chain

- Meet market demand quickly with reliable turnaround times

Partner with us to bring durable, stylish footwear to your market efficiently. Contact our team today to discuss your manufacturing needs!

Visual Guide

Related Products

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

People Also Ask

- How can moc toe boots be styled for casual wear? Master Rugged & Modern Looks

- What is Injection-Molded Construction in work boots? A Guide to Seamless Durability

- What are the main differences between waterproof and water resistant work boots? Choose the Right Boot for Your Job

- Which material provides the best insulation for work boots in cold conditions? Discover the Top Choice for Maximum Warmth

- Why is choosing the right work boot size important? Protect Your Health and Safety on the Job

- What are engineer boots and their characteristics? Unpacking the Iconic Work & Motorcycle Boot

- What are the key safety features to consider when choosing work boots? Ensure Maximum Protection for Your Job

- What daily maintenance steps should be taken for work boots? A Simple 3-Step Routine for Longevity