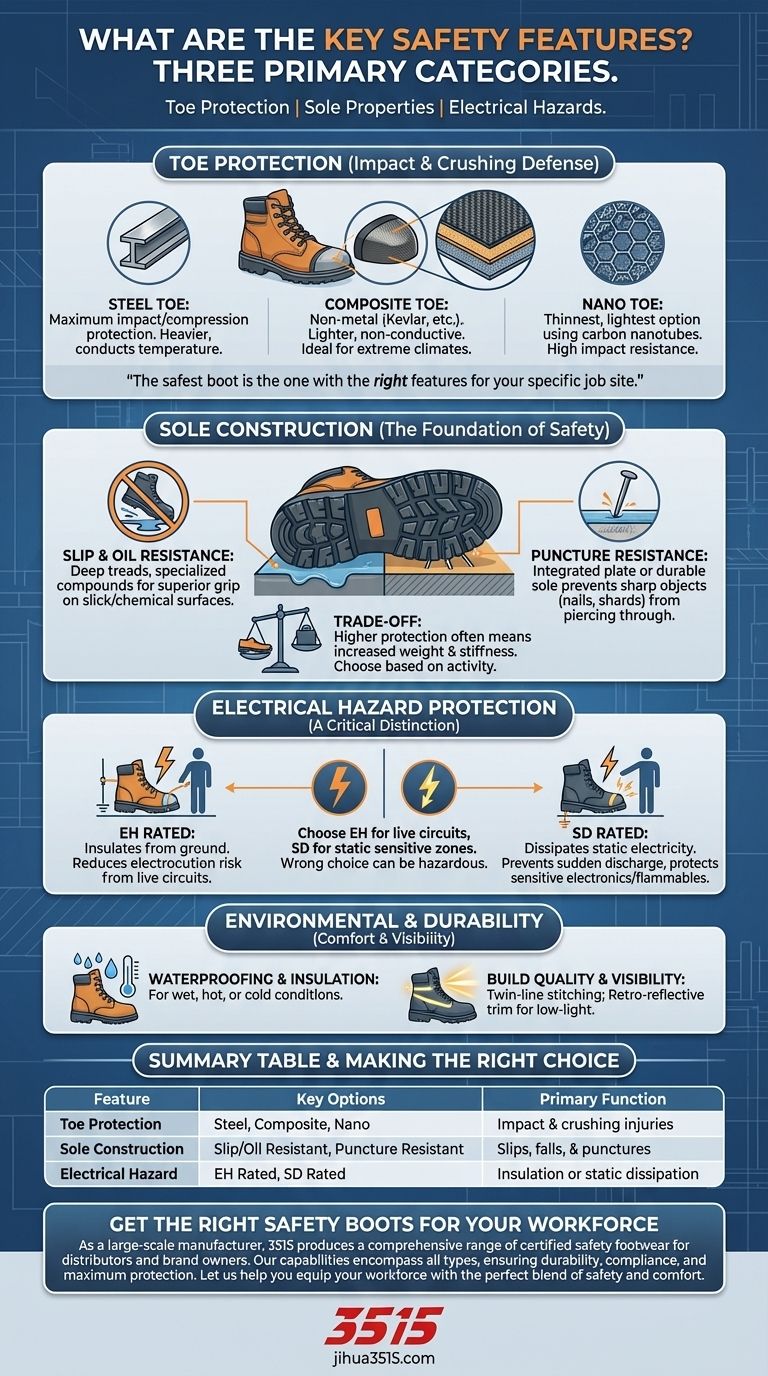

The most critical safety features in work boots fall into three primary categories: toe protection against impact, sole properties for traction and puncture resistance, and safeguards against electrical hazards. These elements are designed to protect you from the most common and severe workplace risks, from falling objects to live circuits.

The safest work boot isn't the one with the most features, but the one with the right features for your specific job site. Understanding the exact hazards you face is the first and most important step in making a correct choice.

Decoding the Primary Lines of Defense

A boot's core safety components are designed to mitigate immediate, high-risk threats. Your evaluation should always start with these foundational features, as they directly correspond to the most serious potential injuries.

Toe Protection: Steel vs. Composite vs. Nano

The safety toe cap is the classic feature people associate with work boots. It protects your feet from crushing and impact injuries caused by heavy or falling objects.

- Steel Toe: This is the traditional standard, offering maximum protection against impact and compression. Its primary trade-off is weight and its conductivity of heat and cold.

- Composite Toe: Made from non-metal materials like Kevlar, carbon fiber, or plastic, these are significantly lighter than steel. They don't conduct electricity or temperature, making them ideal for metal-free environments or extreme climates.

- Nano Toe: This is the most modern option, using carbon nanotubes to create the thinnest and lightest safety toe available. It provides high-impact resistance while feeling much closer to a non-safety boot.

Sole Construction: The Foundation of Safety

The outsole is your direct point of contact with the ground, and its properties are critical for preventing slips, falls, and punctures.

- Slip Resistance: This is essential for any environment with water, oil, or other slick surfaces. Look for boots with deep treads and a sole material designed for superior grip.

- Oil Resistance: The outsole compound is specifically formulated to not degrade or break down when exposed to oil and chemicals, ensuring the boot's longevity and performance.

- Puncture Resistance: A thick, durable sole or an integrated protective plate prevents sharp objects like nails or metal shards from piercing through the bottom of the boot.

Electrical Hazard Protection: A Critical Distinction

This is one of the most misunderstood but vital safety features. The type of electrical protection you need depends entirely on the nature of your work.

- Electrical Hazard (EH) Rated: These boots are designed to insulate you from the ground, significantly reducing the risk of electrocution from accidental contact with live electrical circuits.

- Static Dissipative (SD) Rated: These boots do the opposite. They are designed to reduce the buildup of static electricity on your body, preventing a sudden discharge that could damage sensitive electronic equipment or ignite flammable materials.

Environmental and Durability Features

Beyond the primary threats, a good work boot must be suited for its environment and built to last. These features contribute to your comfort, which directly impacts your long-term safety and focus.

Waterproofing and Insulation

For outdoor work or jobs in wet conditions, a waterproof membrane is non-negotiable for keeping your feet dry and healthy. For work in extreme hot or cold, proper insulation is a safety feature that protects against frostbite or heat stress.

Build Quality and Visibility

High-quality construction, such as twin-line stitching, ensures the boot won't fail under stress. For those working in low-light conditions, retro-reflective trim is a simple feature that dramatically increases your visibility to others.

Understanding the Trade-offs

Choosing a boot involves balancing competing factors. There is no single "best" boot, only the best boot for a specific application.

Protection vs. Weight and Flexibility

Generally, higher levels of protection come with increased weight and stiffness. A heavy-duty steel toe, puncture-proof boot will be less comfortable for a worker who spends all day walking than a lighter composite-toe boot with a more flexible sole.

Specialized vs. General-Purpose Boots

A boot with EH protection is a liability in an environment where static discharge is the primary risk. Likewise, a heavily insulated boot is unsafe in a hot climate. Choosing a boot with features you don't need can introduce unnecessary weight, discomfort, or even new hazards.

The Overlooked Factor: A Proper Fit

An ill-fitting boot is an unsafe boot. It can cause blisters, fatigue, and distraction, leading to slips and falls. A proper fit means about a half-inch of space for your longest toe, a snug heel that doesn't slip, and no pinching or pain while walking.

Making the Right Choice for Your Environment

Your job site's specific hazards are your definitive guide. Use this framework to prioritize features.

- If your primary focus is construction or heavy industry: Prioritize maximum impact protection (steel toe) and puncture-resistant soles.

- If your primary focus is electrical work around live circuits: An EH-rated boot is a non-negotiable requirement.

- If your primary focus is work with sensitive electronics or flammables: You must choose an SD-rated boot to prevent static discharge.

- If your primary focus is on slick surfaces (e.g., auto shops, food processing): The most critical feature is a sole with superior slip and oil resistance.

Ultimately, selecting the right work boot is a direct investment in your daily safety and long-term well-being.

Summary Table:

| Safety Feature | Key Options | Primary Function |

|---|---|---|

| Toe Protection | Steel, Composite, Nano | Protects feet from impact and crushing injuries |

| Sole Construction | Slip/Oil Resistant, Puncture Resistant | Prevents slips, falls, and punctures from sharp objects |

| Electrical Hazard | EH Rated, SD Rated | Insulates from live circuits or dissipates static electricity |

Get the Right Safety Boots for Your Workforce

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We understand that the right boot is the one with the right features for your specific hazards. Our production capabilities encompass all types of safety shoes and boots, ensuring durability, compliance, and maximum protection for your team.

Let us help you equip your workforce with the perfect blend of safety and comfort. Contact our experts today to discuss your requirements and receive a tailored solution.

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- How can one ensure the best fit when buying moc toe boots? Get a Perfect, Comfortable Fit Every Time

- How can moc toe boots be styled for casual wear? Master Rugged & Modern Looks

- Why is it important to check with your employer before purchasing work boots? Ensure Safety & Avoid Costly Mistakes

- How do EH-rated work boots protect against electrical hazards? Insulate Against Shock with Certified Safety

- What are packer boots and how do they differ from regular boots? Specialized Stability for Demanding Work

- What innovative technologies enhance comfort in work boots? Achieve All-Day Comfort and Performance

- What type of conditioner is recommended to prevent color and finish changes on leather boots? Preserve Your Boots' Original Look

- What are the main characteristics of RB (Rubber) as a material for work boots? Unmatched Durability & Slip Resistance