At its core, Injection-Molded Construction is a modern boot-making process where the sole is fused directly to the upper. Instead of using traditional stitching or glue, a molten material like polyurethane or rubber is injected into a mold that contains the boot’s upper, creating a single, seamless, and permanently bonded unit as it cools and solidifies.

This method creates an exceptionally durable and waterproof boot by eliminating the seams that are often the weakest point in footwear. However, this permanent bond means the boots cannot be resoled, representing a trade-off between ultimate durability and long-term repairability.

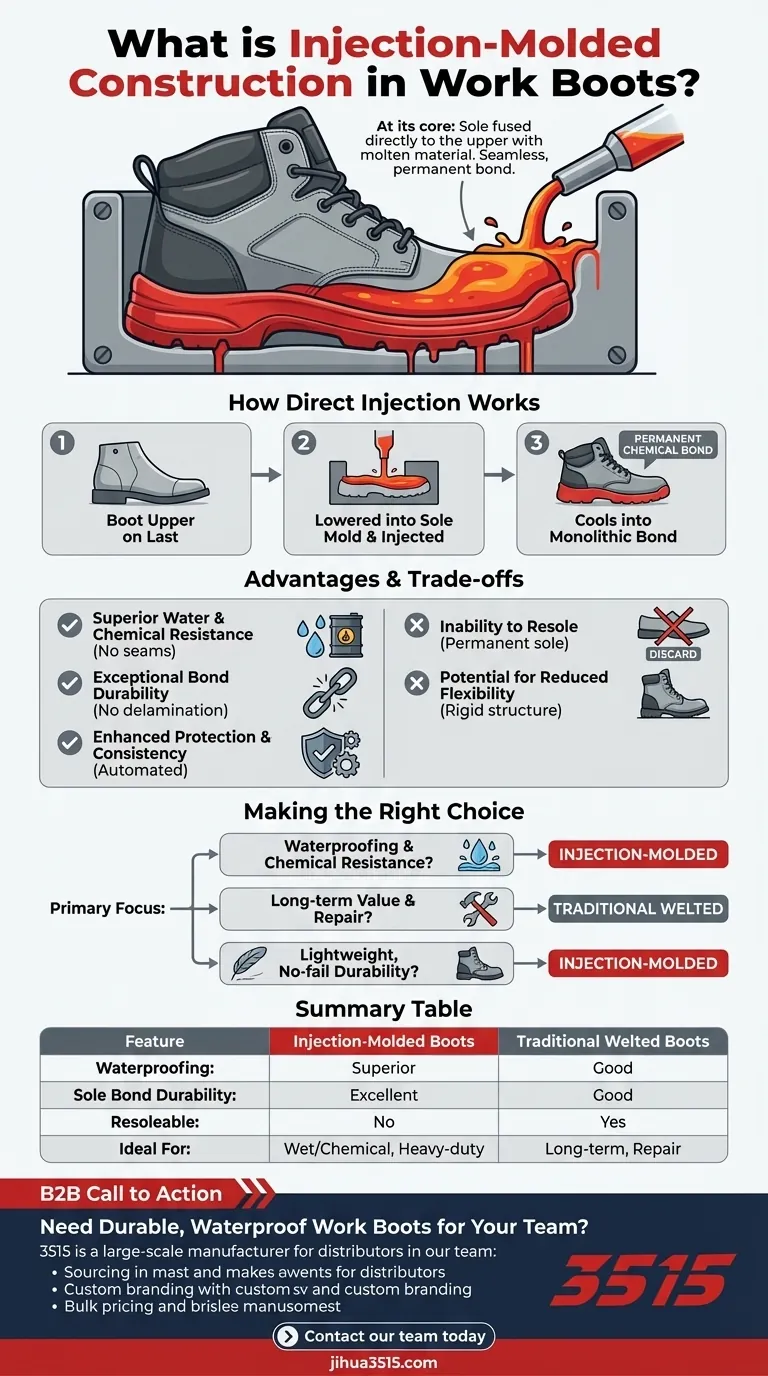

How Direct Injection Construction Works

To understand the benefits and drawbacks of this method, it's essential to visualize the manufacturing process. It is a highly automated and precise technique that differs significantly from traditional bootmaking.

The Manufacturing Process

The process begins by placing a finished boot upper (the part that covers your foot) onto a specialized metal last, or foot form. This entire assembly is then lowered into a sole mold.

Liquid polymer, typically Polyurethane (PU) or Thermo-Plastic Urethane (TPU), is then injected under high pressure into the mold cavity. The liquid flows to perfectly fill the shape of the outsole while simultaneously penetrating the fibers of the upper.

The Result: A Monolithic Bond

As the material cools and hardens, it creates a permanent chemical bond with the upper. This isn't just an adhesive layer; it's a true fusion of two separate parts into a single, cohesive unit. The result is a boot with no stitches or glue seams connecting the sole to the rest of the boot.

The Core Advantages of This Method

The unique manufacturing process yields specific, high-performance advantages that make these boots ideal for certain demanding environments.

Superior Water and Chemical Resistance

Because there are no stitched seams for water or chemicals to penetrate, injection-molded boots offer a superior level of waterproofing. The seamless bond forms a watertight seal around the entire base of the boot, which is critical in wet or hazardous liquid environments.

Exceptional Bond Durability

The primary failure point for many work boots is "delamination," where the outsole separates from the upper. The chemical bond created during injection molding is incredibly strong and permanent, virtually eliminating this risk. The sole will wear out long before it ever peels off.

Enhanced Protection and Consistency

The one-piece outsole construction provides excellent protection from punctures and impacts. The process is also highly automated, ensuring a consistent quality and fit from one pair to the next, which is not always guaranteed with manual construction methods.

Understanding the Trade-offs

No construction method is perfect for every application. The strengths of injection molding also create its primary limitation.

The Inability to Resole

The greatest strength of the injection-molded bond is also its main drawback. The fusion is so permanent that the sole cannot be removed and replaced. Once the tread has worn down, the entire boot must be discarded.

Potential for Reduced Flexibility

While modern materials have improved this, the rigid, single-unit construction can sometimes be less flexible than a boot with a traditional stitched welt. This may lead to a slightly longer break-in period for some users.

Making the Right Choice for Your Goal

Selecting the right boot construction depends entirely on the demands of your job and your priorities for the footwear.

- If your primary focus is maximum waterproofing and chemical resistance: Injection-molded construction is the superior choice for work in wet environments, food processing, or chemical plants.

- If your primary focus is long-term value through repair: You should consider a traditional Goodyear welt construction, which is designed specifically to be resoled multiple times.

- If your primary focus is lightweight, no-fail durability for general use: Injection-molded boots provide an excellent balance of toughness and comfort without the weight or maintenance of older methods.

Ultimately, choosing the right boot construction is about matching the tool to the task for optimal safety and performance.

Summary Table:

| Feature | Injection-Molded Boots | Traditional Welted Boots |

|---|---|---|

| Waterproofing | Superior (seamless bond) | Good (depends on sealing) |

| Sole Bond Durability | Excellent (no delamination) | Good (can delaminate over time) |

| Resoleable | No | Yes |

| Ideal For | Wet/chemical environments, general heavy-duty use | Long-term value, repairability |

Need Durable, Waterproof Work Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of injection-molded footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, ensuring superior waterproofing and exceptional bond durability for demanding work environments.

We can help you:

- Source reliable safety footwear that meets your specific industry standards.

- Develop custom-branded work boots with the exact features your customers need.

- Secure bulk pricing on high-performance, durable footwear.

Let's discuss your requirements → Contact our team today to get a quote or request a catalog!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What are the different styles of women's work boots available? Find Your Perfect Fit for Safety & Comfort

- What are the key differences between work boots and western boots? Choose the Right Boot for Safety or Style

- What are the essential features of fire boots? A Guide to Maximum Safety & Performance

- What is the significance of waterproof and breathable properties in work footwear? Boost Safety in Wet Conditions

- Why is rotating footwear important for moc toe boots? Extend Their Lifespan & Comfort

- Why is choosing the right footwear important for farming and gardening? Protect Your Feet, Boost Productivity

- Why is measuring your feet important when buying work boots? Avoid Pain & Boost Safety

- What are the key features of forestry boots? Essential Protection for Chainsaw Operators