To safely test the slip resistance of shoes, you must combine a careful visual inspection of the outsole with a controlled physical test. The safest method involves finding a small patch of a slick surface, like tile, using a stable object for support, and cautiously applying pressure to feel for grip rather than risking a full-body slip.

The true measure of a slip-resistant shoe is not just its material, but its engineering. An effective design actively channels liquids like water and oil away from the sole, similar to car tires on a wet road, which is the key to maintaining grip and preventing accidents.

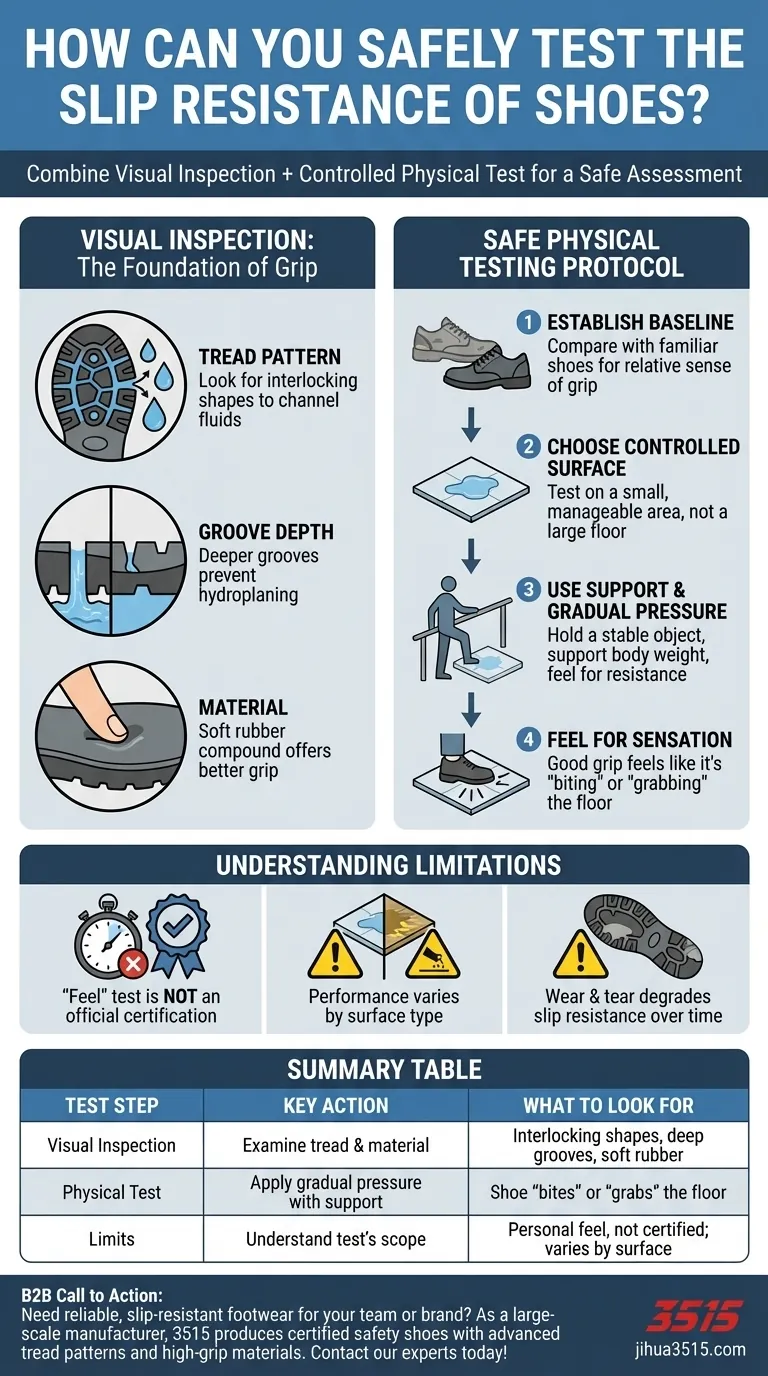

The Foundation of Grip: What to Look For Before You Test

Before you even step onto a wet surface, a quick visual inspection of the shoe's outsole can reveal its true capabilities. The design and material are the primary indicators of performance.

The Critical Role of Tread Pattern

The shapes carved into the bottom of the shoe are not for aesthetics; they are engineered to displace liquid. Look for interlocking patterns like small hexagons or circles. These shapes create channels that push water and oil out from under the sole, allowing the rubber to make direct contact with the floor.

Why Groove Depth Matters

Shallow treads can easily become clogged with liquid, leading to hydroplaning. Deeper grooves provide more space to channel fluids away and create higher friction against the walking surface. A deeper, more aggressive tread is a strong sign of a capable shoe.

The Material Advantage: Soft Rubber Compounds

The material of the outsole is crucial. A high-grade, softer rubber compound offers a better grip, especially on greasy or oily surfaces, than hard, inflexible plastic. Gently press your fingernail into the sole; a slight give often indicates a softer, grippier material.

A Protocol for Safe Physical Testing

Once you've visually inspected the shoe, you can perform a cautious physical test to confirm its grip. The goal is to feel the traction, not to induce a fall.

Step 1: Establish a Baseline

If possible, compare the new shoes with a pair you are familiar with, such as old work shoes or sneakers. This gives you a relative sense of grip and helps you judge the performance of the new pair more accurately.

Step 2: Choose a Controlled Test Surface

Find a small, non-porous surface like a single tile, a patch of linoleum, or a polished stone floor. Do not test on a large, open, wet floor. The area should be small and manageable.

Step 3: Use a Support and Test with Gradual Pressure

This is the most critical step for safety. Stand next to a stable counter, railing, or heavy piece of furniture you can hold firmly. Place your foot on the wet patch and, while supporting your body weight with your arms, gradually apply pressure and attempt to slide your foot forward and side-to-side.

Step 4: Pay Attention to the Sensation

You are not trying to slip. You are feeling for the shoe's response. A good slip-resistant shoe will feel like it's "biting" or "grabbing" the floor, resisting the sliding motion. A poor shoe will feel slick and slide easily with minimal pressure.

Understanding the Limitations and Pitfalls

A personal test provides valuable insight, but it's essential to recognize its limits to ensure you remain safe.

A "Feel" Test Is Not a Certification

This method is an excellent personal assessment, but it does not replace official industry ratings (like those from ASTM). For high-risk professional environments, always look for shoes that are officially certified as slip-resistant.

Surface Type Changes Everything

Excellent performance on a wet tile floor does not guarantee the same level of grip on a greasy kitchen floor. Your test is only a reliable indicator for the specific conditions and surface you tested on.

Wear and Tear Degrades Performance

Slip resistance is not permanent. As the shoe's outsole wears down, the tread patterns become shallower and less effective. You should visually inspect your shoes regularly and re-test them if you notice significant wear.

Making the Right Choice for Your Environment

Your environment dictates how rigorously you need to assess your footwear. Use your visual inspection and physical test to make an informed decision based on your specific needs.

- If your primary focus is daily safety in a low-risk area (e.g., an office with polished floors): A thorough visual inspection for proper tread design combined with a simple, cautious feel test is sufficient.

- If your primary focus is a high-risk work environment (e.g., a commercial kitchen, hospital, or factory): Prioritize shoes with official slip-resistance ratings first, and use the physical test only as a secondary confirmation of performance.

- If you are evaluating the wear on your current shoes: Periodically inspect the tread depth and re-perform the supported feel test to determine if the shoes have lost their grip and need to be replaced.

By combining an understanding of slip-resistant design with a cautious physical test, you can make a confident and informed decision about your footwear's safety.

Summary Table:

| Test Step | Key Action | What to Look For |

|---|---|---|

| Visual Inspection | Examine outsole tread pattern and material. | Interlocking shapes (hexagons), deep grooves, soft rubber. |

| Physical Test | Apply gradual pressure on a small, wet tile while holding support. | Shoe "bites" or "grabs" the floor, resisting a slide. |

| Limits | Understand the test's scope. | Performance varies by surface; test is not an official certification. |

Need reliable, slip-resistant footwear for your team or brand? As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our expertise in engineering outsoles with advanced tread patterns and high-grip materials ensures superior protection against slips and falls. Let us help you equip your workforce with confidence. Contact our experts today to discuss your production needs!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What are the benefits of specialized shoes for doctors? Enhance Comfort, Safety, and Endurance

- Why are water and stain resistance important features in chef shoes? Essential for Kitchen Safety & Hygiene

- What are the common types of non-slip shoes? Find the Right Grip for Any Environment

- Why are chemical cleaners containing surfactants used in slip-resistant footwear research? Achieve Critical Safety.

- What is the difference between anti-slip and non-slip terminology? Uncover the Truth for Real Safety

- Why are slip-resistant shoes important for certain jobs? Prevent Costly Workplace Injuries

- Why are slip-resistant shoes important for chefs? The Foundation of Kitchen Safety and Performance

- What household items can make shoes non-slip? Quick Fixes vs. Professional Solutions