When it comes to non-slip footwear, the most common types are defined by their intended use, including slip-resistant work shoes, safety boots, athletic shoes, and even some casual footwear. These shoes all share a core technology: an outsole specifically engineered with materials and patterns designed to maximize grip and reduce the risk of slipping on hazardous surfaces.

The terms "non-slip" and "slip-resistant" are functionally the same, but neither is officially regulated. Therefore, true effectiveness is not determined by the label, but by the physical characteristics of the shoe's outsole—specifically its material and tread pattern.

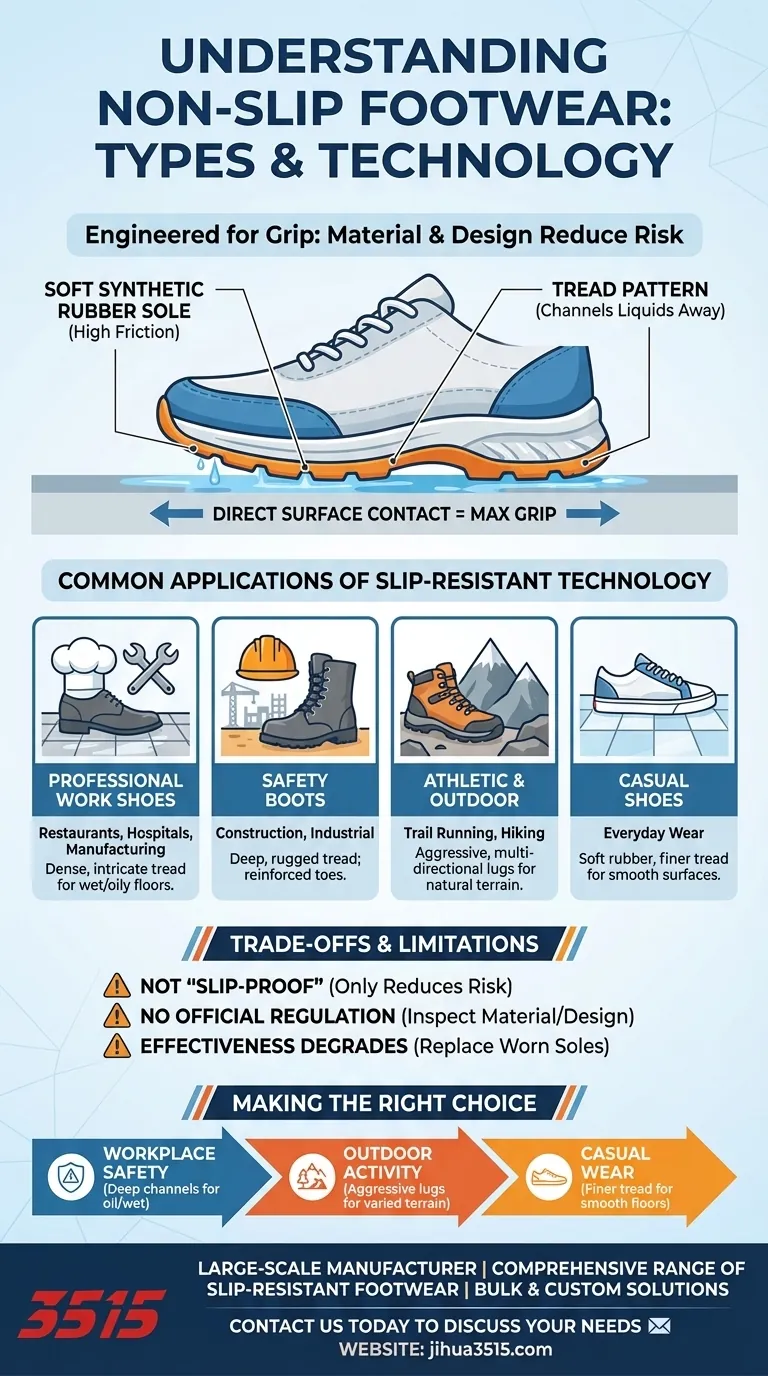

What Truly Defines a "Non-Slip" Shoe?

The promise of a non-slip shoe isn’t just marketing; it’s rooted in the specific engineering of the sole. Understanding these components allows you to look past the label and assess the shoe's true capability.

The Terminology: Non-Slip vs. Slip-Resistant

The terms non-slip and slip-resistant are used interchangeably by manufacturers and experts alike.

While "slip-resistant" is the more formal term preferred by safety organizations, there is no official government or industry standard that a shoe must meet to use either label.

The Critical Component: The Outsole

A shoe's ability to resist slips is determined almost entirely by its outsole (the very bottom of the shoe that contacts the ground). Two factors are paramount: the material and the design.

Material Matters: The Power of Rubber

The vast majority of effective slip-resistant shoes use a soft, synthetic rubber sole.

This material has a high coefficient of friction, which means it naturally creates more grip against a surface, especially when compared to harder, less flexible materials like leather or dense plastics.

Design is Key: The Tread Pattern

The pattern of grooves and channels on the outsole is the tread. Its job is to channel water, oil, and other contaminants away from the sole's point of contact with the floor.

By clearing this path, the tread allows the rubber to make direct, solid contact with the surface, which is essential for maintaining grip.

Common Applications of Slip-Resistant Technology

While the underlying technology is similar, it is applied to different types of footwear to meet specific environmental demands.

Professional Work Shoes

These are designed for environments like restaurant kitchens, hospitals, or manufacturing floors where wet and oily surfaces are a constant hazard. They typically feature intricate, dense tread patterns.

Safety Boots

Often required in construction or industrial settings, these boots combine slip-resistant outsoles with other safety features like reinforced steel or composite toes. The tread is often deeper and more rugged.

Athletic and Outdoor Footwear

Trail running and hiking shoes rely on slip-resistant technology for a different reason: gripping uneven, loose, or wet natural terrain. Their tread patterns often feature aggressive, multi-directional "lugs" for traction.

Casual Shoes

More manufacturers are incorporating softer rubber soles and effective tread patterns into everyday casual shoes, providing an extra layer of safety for walking on smooth, potentially wet surfaces like tile floors or polished concrete.

Understanding the Trade-offs and Limitations

Objectivity is crucial when it comes to safety. Recognizing the limitations of this technology helps you make a more informed decision and stay safer.

No Shoe is "Slip-Proof"

The term is "slip-resistant," not "slip-proof." These shoes significantly reduce the risk of falling, but they cannot eliminate it entirely. Extreme conditions, such as large oil spills or ice, can still overcome any shoe's grip.

The Lack of Regulation is a Challenge

Because there is no universal standard, the performance between two pairs of shoes both labeled "non-slip" can vary dramatically. This makes it essential for you to physically inspect the sole's material and design.

Effectiveness Degrades Over Time

As the outsole wears down, the tread pattern becomes shallower and less effective at channeling away liquids. A worn-out non-slip shoe loses its primary safety feature and should be replaced.

Making the Right Choice for Your Goal

To select the right footwear, match the sole's characteristics to the environment where you will be wearing them.

- If your primary focus is workplace safety: Look for shoes with deep, channel-like treads specifically rated for oily and wet conditions.

- If your primary focus is outdoor activity: Prioritize shoes with aggressive, multi-directional tread patterns (lugs) made from durable rubber for grip on varied terrain.

- If your primary focus is everyday casual wear: Choose shoes with soft rubber soles and a finer tread pattern that maximizes surface contact on smooth floors.

Ultimately, understanding the sole's material and design is the key to finding footwear that delivers genuine safety.

Summary Table:

| Type of Non-Slip Shoe | Primary Use Case | Key Outsole Characteristics |

|---|---|---|

| Professional Work Shoes | Restaurant kitchens, hospitals, manufacturing | Dense, intricate tread patterns for wet/oily floors |

| Safety Boots | Construction, industrial sites | Deep, rugged tread; often includes steel/composite toes |

| Athletic & Outdoor Footwear | Trail running, hiking | Aggressive, multi-directional lugs for natural terrain |

| Casual Shoes | Everyday wear on smooth surfaces | Soft rubber soles with finer tread patterns |

Need reliable, high-performance non-slip footwear for your business or customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, engineered with the optimal materials and tread patterns for maximum safety and durability.

Contact us today to discuss your specific needs and discover how we can deliver the perfect non-slip solution for your market.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals