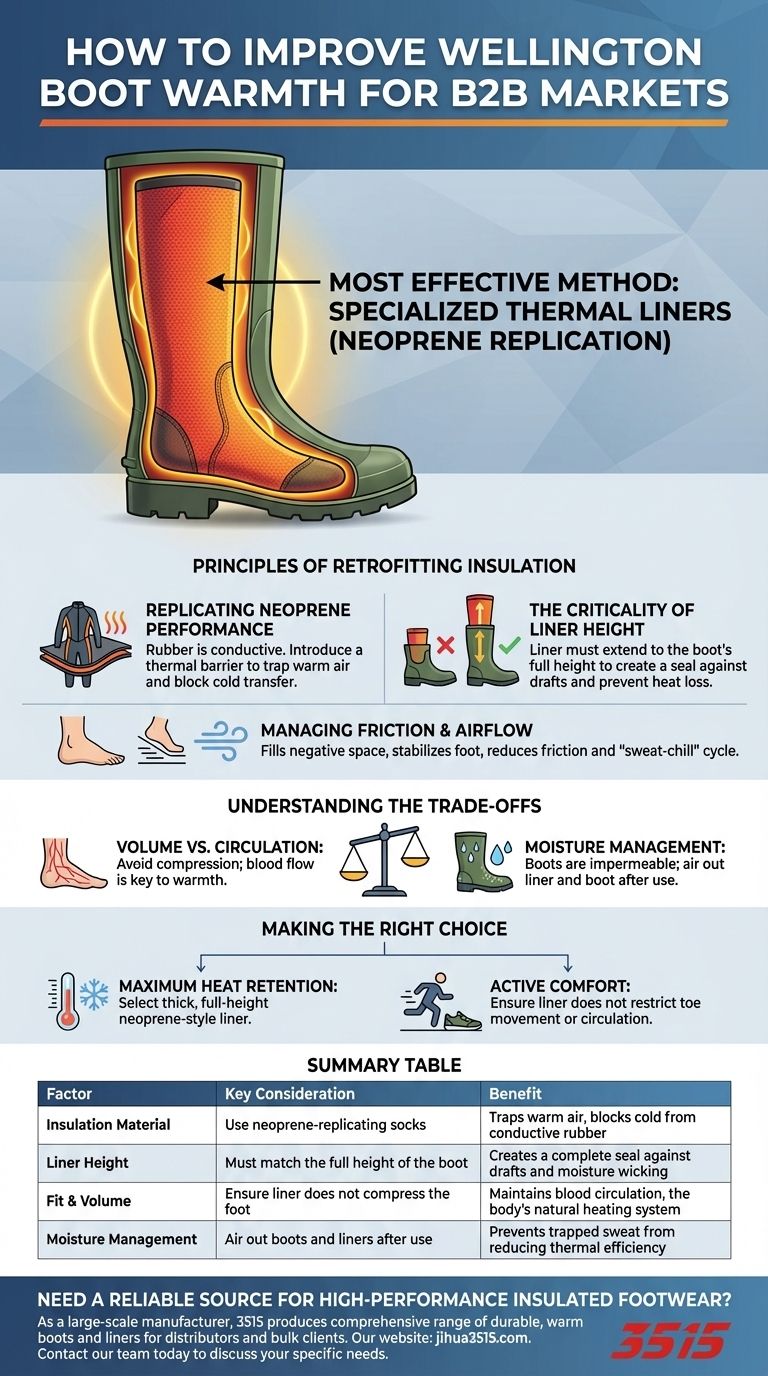

The most effective method to upgrade the thermal retention of standard rubber boots is the addition of a specialized thermal liner. To significantly improve warmth, you should utilize purpose-built welly socks designed to replicate the insulating properties of a neoprene lining. These liners must extend to the full height of the boot to create a seal against cold drafts and prevent conductive heat loss through the rubber shell.

Standard rubber boots excel at waterproofing but often lack inherent thermal retention. The key to warmth lies not in changing the boot itself, but in retrofitting it with a lining that traps heat and separates your foot from the cold, conductive rubber.

Principles of Retrofitting Insulation

Replicating Neoprene Performance

The primary deficiency in standard Wellington boots is the lack of a thermal core. Rubber is a conductor, meaning it transfers the cold from the ground directly to your foot.

To counter this, you must introduce a barrier. Using socks that replicate a neoprene lining adds a layer of synthetic insulation akin to a wetsuit. This traps a layer of warm air against the skin while blocking the cold radiating from the boot wall.

The Criticality of Liner Height

Insulation is only effective if the seal is complete. A common mistake is using standard-length socks inside tall boots.

For maximum efficiency, the thermal sock must be the same length as the boot. This prevents cold air from "sinking" into the gap between your leg and the boot collar. It also stops moisture from wicking down from the top edge.

Managing Friction and Airflow

Cold is often exacerbated by poor circulation or dampness. A loose boot allows the foot to slide, generating friction and potentially blisters, while a cold rubber wall causes condensation.

A full-length, neoprene-style sock fills the negative space inside the boot. This stabilizes the foot, reducing friction. Furthermore, by preventing the foot from touching the cold rubber directly, you reduce the "sweat-chill" cycle that creates cold feet.

Understanding the Trade-offs

The Volume vs. Circulation Paradox

While adding thick, neoprene-replicating socks improves insulation, it also consumes volume inside the boot.

If your boots are already snug, adding a thick liner may compress your foot. Compression restricts blood flow, which is the body's primary heating mechanism. If the sock is too tight, your feet will become colder regardless of the insulation thickness.

Moisture Management Limitations

Unlike high-end military boots which often utilize GORE-TEX membranes to allow moisture escape, standard wellies are impermeable.

Adding a warm liner increases the likelihood of sweating. Because the rubber shell does not breathe, this moisture is trapped. You must ensure you air out both the boot and the liner after every use to maintain thermal efficiency.

Making the Right Choice for Your Goal

To solve your specific problem, apply the following principles:

- If your primary focus is maximum heat retention: Select a thick, neoprene-style sock liner that reaches the very top of the boot to maximize the insulating air gap.

- If your primary focus is active comfort: Ensure the added liner does not restrict toe movement or circulation, as blood flow is critical for warmth during movement.

By effectively managing the internal environment of the boot with the right liner height and material, you transform a simple rain shell into a thermal tool.

Summary Table:

| Factor | Key Consideration | Benefit |

|---|---|---|

| Insulation Material | Use neoprene-replicating socks | Traps warm air, blocks cold from conductive rubber |

| Liner Height | Must match the full height of the boot | Creates a complete seal against drafts and moisture wicking |

| Fit & Volume | Ensure liner does not compress the foot | Maintains blood circulation, the body's natural heating system |

| Moisture Management | Air out boots and liners after use | Prevents trapped sweat from reducing thermal efficiency |

Need a reliable source for high-performance insulated footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and warm boots and liners for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of insulated and waterproof footwear, ensuring your customers stay warm and dry in any condition.

Contact our team today to discuss your specific needs and discover how we can provide the thermal solutions you require.

Visual Guide

Related Products

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- What factors should be considered when selecting waterproof snow boots for men? A Technical Guide

- How does the tread design of PVC boots enhance functionality? Boost Safety and Comfort for Your Workforce

- Can wellies be worn year-round? A Practical Guide to All-Weather Footwear

- Should you buy toddler wellies a size larger than normal? Prioritize Safety and a Perfect Fit

- How can you measure your calf for wellington boots? Get the Perfect Fit for All-Day Comfort

- What are some features of FSC-certified Wellington boots available in the UK? Sustainable, Durable & Ethical Footwear

- What materials are used in women's wellies? A Guide to Rubber, Neoprene & PVC

- What are the key considerations when choosing wellies for babies and toddlers? Ensure Safety and Comfort for Active Play