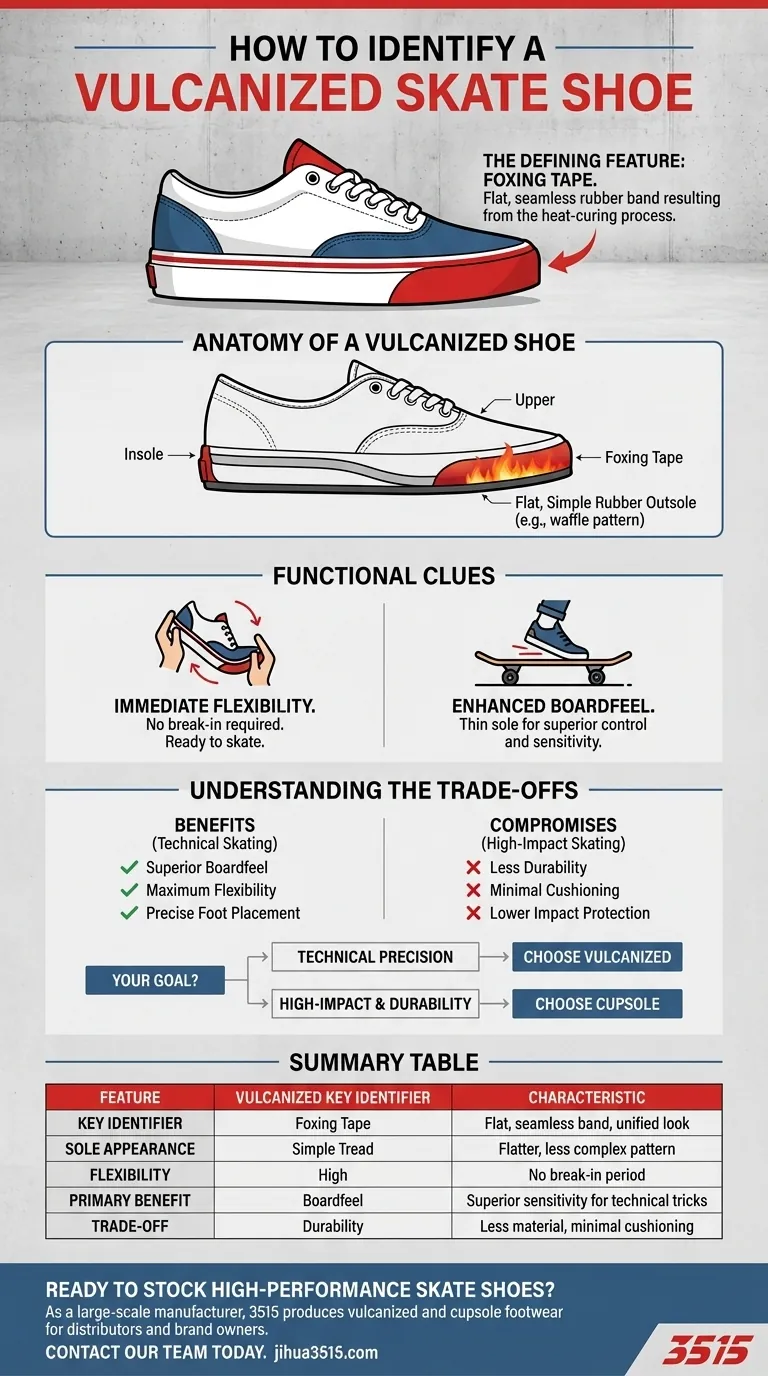

The simplest way to identify a vulcanized skate shoe is by looking for the flat, seamless band of rubber, known as foxing tape, that wraps around the side of the shoe where the upper connects to the sole. This band is a direct result of the vulcanization process, where the sole is heat-cured to the rest of the shoe, creating a distinct, unified look.

Understanding the visual cues of a vulcanized shoe is less about identifying a single feature and more about recognizing a design philosophy. This construction method prioritizes boardfeel and flexibility, and its characteristics are a direct reflection of that goal.

The Anatomy of a Vulcanized Shoe

A vulcanized shoe's construction is fundamentally different from that of a cupsole, and this difference is visible in its key components.

The Defining Feature: Foxing Tape

The most reliable indicator is the foxing tape. This is a flat strip of rubber that runs around the entire perimeter of the shoe.

This tape is not just decorative; it's a structural part of the shoe. During the vulcanization process, the upper and the outsole are essentially baked together in a large oven, fusing the foxing tape and creating a single, cohesive unit.

The Sole's Appearance

Vulcanized soles typically appear flatter and less complex than their cupsole counterparts. You won't see deep, multi-level treads or separate midsole components visible from the side.

The bottom tread is often a classic pattern like a waffle or herringbone, designed for maximum grip and a consistent feel underfoot.

Functional Clues: Feel and Flexibility

Beyond visual inspection, the feel of the shoe provides strong clues to its construction.

Immediate Flexibility

Right out of the box, a vulcanized shoe is noticeably flexible and pliable. You can easily bend and twist the shoe with your hands.

This inherent flexibility means the shoe requires almost no break-in period. It feels ready to skate from the first wear.

Enhanced Boardfeel

The primary reason skaters choose vulcanized construction is for superior boardfeel. The thin, flat sole allows you to feel the contours of your board with much greater sensitivity.

This direct connection is ideal for technical skating where precise foot placement and subtle adjustments are critical for landing tricks.

Understanding the Trade-offs

Choosing a vulcanized shoe involves accepting a specific set of compromises in exchange for its unique benefits.

Durability vs. Boardfeel

The thin sole that provides excellent boardfeel is also less durable. The single layer of rubber offers less material to wear through and less cushioning against impacts.

Skaters who do a lot of high-impact tricks, like jumping down large sets of stairs, may find that vulcanized shoes wear out faster and offer insufficient protection.

Support and Cushioning

The streamlined, heat-fused construction leaves little room for advanced cushioning technologies. The sole is primarily rubber, offering minimal impact absorption.

This lack of structural support can lead to more foot fatigue and bruising, especially during long sessions or when skating high-impact obstacles.

Making the Right Choice for Your Goal

Ultimately, identifying a vulcanized shoe is the first step toward deciding if it's the right tool for your specific style of skating.

- If your primary focus is technical precision and board control: A vulcanized shoe is the ideal choice, as its flexibility and thin sole provide unmatched sensitivity.

- If your primary focus is high-impact skating and durability: You may want to look for a cupsole shoe, which offers superior cushioning and a longer lifespan.

Knowing how to spot a vulcanized shoe empowers you to choose the equipment that best serves your needs on the board.

Summary Table:

| Feature | Vulcanized Skate Shoe | Key Identifier |

|---|---|---|

| Foxing Tape | Flat, seamless rubber band wrapping the sole | Visible, unified look from the vulcanization process |

| Sole Appearance | Flatter, less complex tread (e.g., waffle/herringbone) | Simpler design compared to cushioned cupsoles |

| Flexibility | Highly flexible, requires no break-in period | Easy to bend and twist by hand |

| Primary Benefit | Superior boardfeel and sensitivity for technical tricks | Ideal for precise foot control and skateboard connection |

| Trade-off | Less durable sole, minimal impact cushioning | Wears faster on high-impact obstacles |

Ready to Stock High-Performance Skate Shoes?

As a large-scale manufacturer, 3515 produces a comprehensive range of vulcanized and cupsole footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the right shoe for every skater's need—whether they prioritize technical boardfeel or high-impact durability.

Let's discuss your next order: Contact our team today to explore our catalog and leverage our expertise in skate shoe manufacturing!

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- What are the benefits of breathable mesh in shoe design? Enhance Comfort and Performance

- How do athletic shoes with non-slip features differ from regular ones? Discover the Grip Advantage

- What is high-tech 'air' mesh, and how is it used in footwear? The Key to Cool, Lightweight Shoes

- What are the features of cross training shoes? Master Versatile Performance for Your Workouts

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team