The most reliable way to determine the right safety toe boot is to consult your employer's official safety plan and assess the specific hazards of your work environment. This isn't just a suggestion; it's the mandatory first step. Your workplace requirements will dictate the necessary safety ratings, from protection against falling objects to specialized needs like electrical hazard protection.

Choosing a safety boot is a critical risk management decision, not a simple footwear purchase. The right choice is found by first understanding your workplace's mandated requirements, then matching the boot's specific protective features and fit to the realities of your daily tasks.

The Starting Point: Workplace Requirements

Your selection process must begin with official guidance. Personal preference is secondary to mandated safety protocols that have been established for your protection.

Always Consult Your Employer First

Your employer or safety manager is the definitive source for determining the appropriate safety footwear. They are responsible for assessing workplace hazards and establishing the minimum protective standards you must follow.

This guidance removes guesswork and ensures you are in full compliance with company and regulatory safety standards.

Deconstruct Your Safety Plan

The workplace safety plan will specify the exact type of protection needed for your role. It will move beyond general requirements and identify the need for specific, certified features.

Look for key terms like EH-rated for environments with electrical hazards or SD-rated for roles requiring static dissipative footwear to protect sensitive equipment.

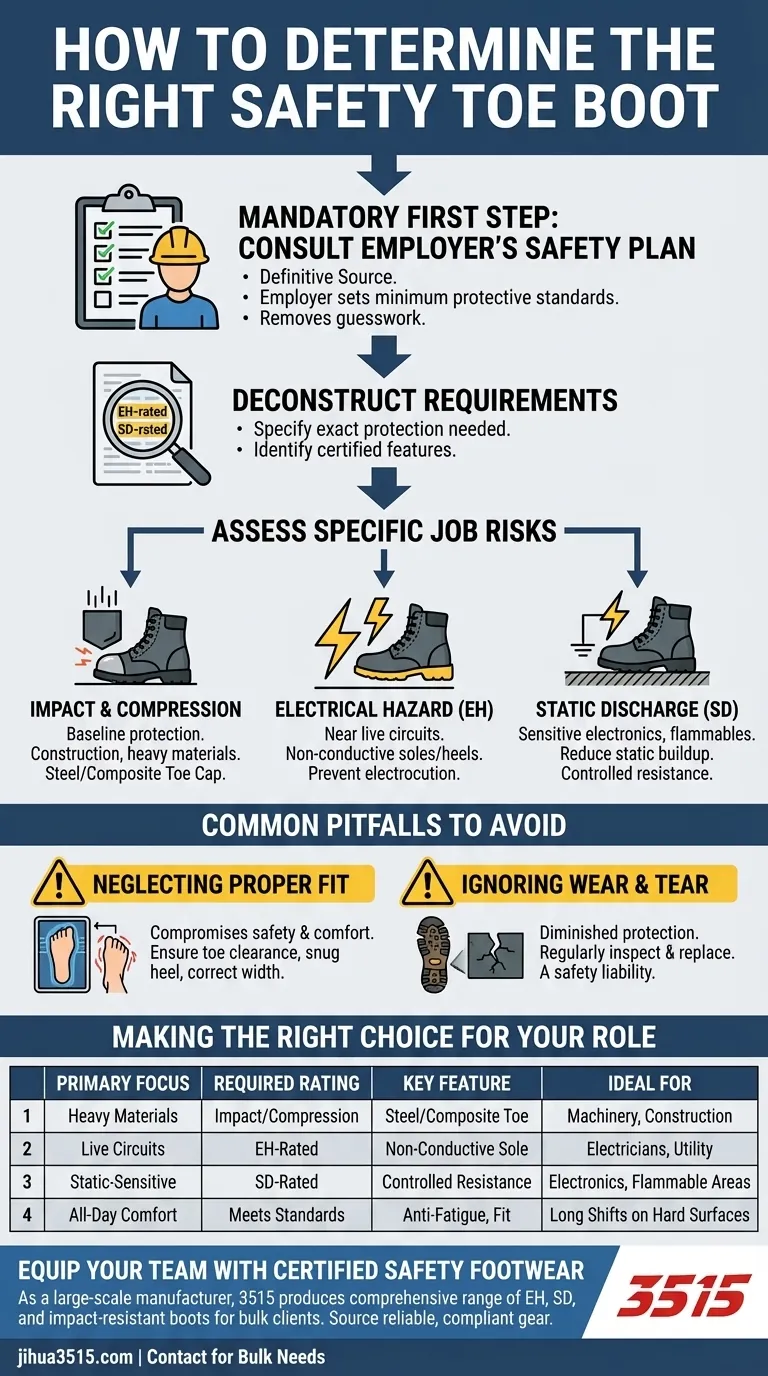

Assessing Your Specific Job Risks

Once you know the required standards, you can evaluate boots based on the daily hazards you face. Safety equipment is a preventative measure tailored to mitigate specific, known risks.

Impact and Compression

The foundational purpose of a safety toe boot is to protect your feet from the impact of falling objects and the compression from rolling equipment. This is the baseline feature for most industrial and construction environments.

Electrical Hazard (EH) Protection

If you work near live electrical circuits, an EH-rated boot is non-negotiable. These boots are designed with non-conductive soles and heels to provide a secondary source of protection against accidental electrocution.

Static Discharge (SD) Needs

In contrast to EH boots, SD-rated footwear is designed to reduce the buildup of static electricity. This is crucial in environments with sensitive electronics or flammable materials where a static spark could be catastrophic.

Common Pitfalls to Avoid

Even with the right safety rating, a boot can fail to protect you if fundamental mistakes are made during selection and use.

Neglecting a Proper Fit

An improper fit compromises both safety and comfort. Ensure there is adequate toe clearance so your toes aren't cramped. The boot should have a snug heel fit to prevent slipping and blisters, and the width must be appropriate for your foot.

Some retailers offer foot scanning technology to get a precise measurement, which can be invaluable for achieving a perfect fit.

Ignoring Wear and Tear

Safety boots are tools with a limited lifespan. As soles wear down and materials degrade, their protective qualities diminish significantly.

You must regularly inspect your boots and replace them when they show signs of being worn out. A compromised boot is a safety liability.

Making the Right Choice for Your Role

Use this framework to align your boot choice with your primary job function and its associated hazards.

- If your primary focus is working around heavy materials or machinery: Prioritize a boot with the highest impact and compression rating that meets your employer's standards.

- If your primary focus is protection from live electrical circuits: You must select a boot explicitly labeled with an Electrical Hazard (EH) rating.

- If your primary focus is preventing static electricity buildup: Look for a Static Dissipative (SD) rated boot to protect sensitive components or prevent ignition of flammable materials.

- If your primary focus is all-day comfort on hard surfaces: After meeting all safety requirements, consider features like anti-fatigue insoles and ensure a perfect fit to minimize strain.

By systematically matching your workplace requirements to the right boot features, you ensure your safety gear is a reliable preventative measure, not an afterthought.

Summary Table:

| Job Hazard | Required Safety Rating | Key Feature |

|---|---|---|

| Heavy Materials/Machinery | Impact/Compression Rated | Steel/Composite Toe Cap |

| Live Electrical Circuits | EH-Rated | Non-Conductive Sole & Heel |

| Static-Sensitive Environments | SD-Rated | Controlled Electrical Resistance |

| All-Day Comfort | Meets Safety Standards | Anti-Fatigue Insoles, Proper Fit |

Ensure Your Team is Equipped with the Right Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, including EH-rated, SD-rated, and impact/compression-resistant models, tailored to meet the specific hazards of your workplace.

We help you source reliable, compliant safety footwear that protects your team and meets your employer's mandated safety standards. Contact us today to discuss your bulk safety footwear needs and receive a customized solution.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How does protective footwear benefit employers? Slash Costs & Boost Productivity

- What are the long-term benefits of following work shoe maintenance tips? Boost Safety & Save Money

- Are there vegan firefighter boots available? Yes, NFPA-Certified & High-Performance

- What are the properties of polyurethane (PU) outsoles in safety shoes? Discover the Perfect Blend of Lightweight Protection and Comfort

- What are electric hazard work boots and who should wear them? Essential Safety for Electrical Workers

- What is the importance of slip-resistant outsole technology in high-performance safety footwear? Protect Your Workforce

- Why is a professional foot protection solution essential for the hygiene lock process in poultry farming? Secure Your Flock

- Why is metatarsal protection required on job sites? Essential Safety for Heavy-Duty Work