Metatarsal protection is required on job sites to shield the five long, delicate bones on the top of the foot from severe impact and compression. This requirement addresses specific, high-level hazards that go beyond the protection offered by standard safety-toe boots, which only shield the toes themselves.

While standard safety-toe footwear protects the front of the foot, metatarsal guards provide crucial, extended coverage for the entire instep. This area is uniquely vulnerable to crushing injuries from heavy objects that can fall or roll onto the foot.

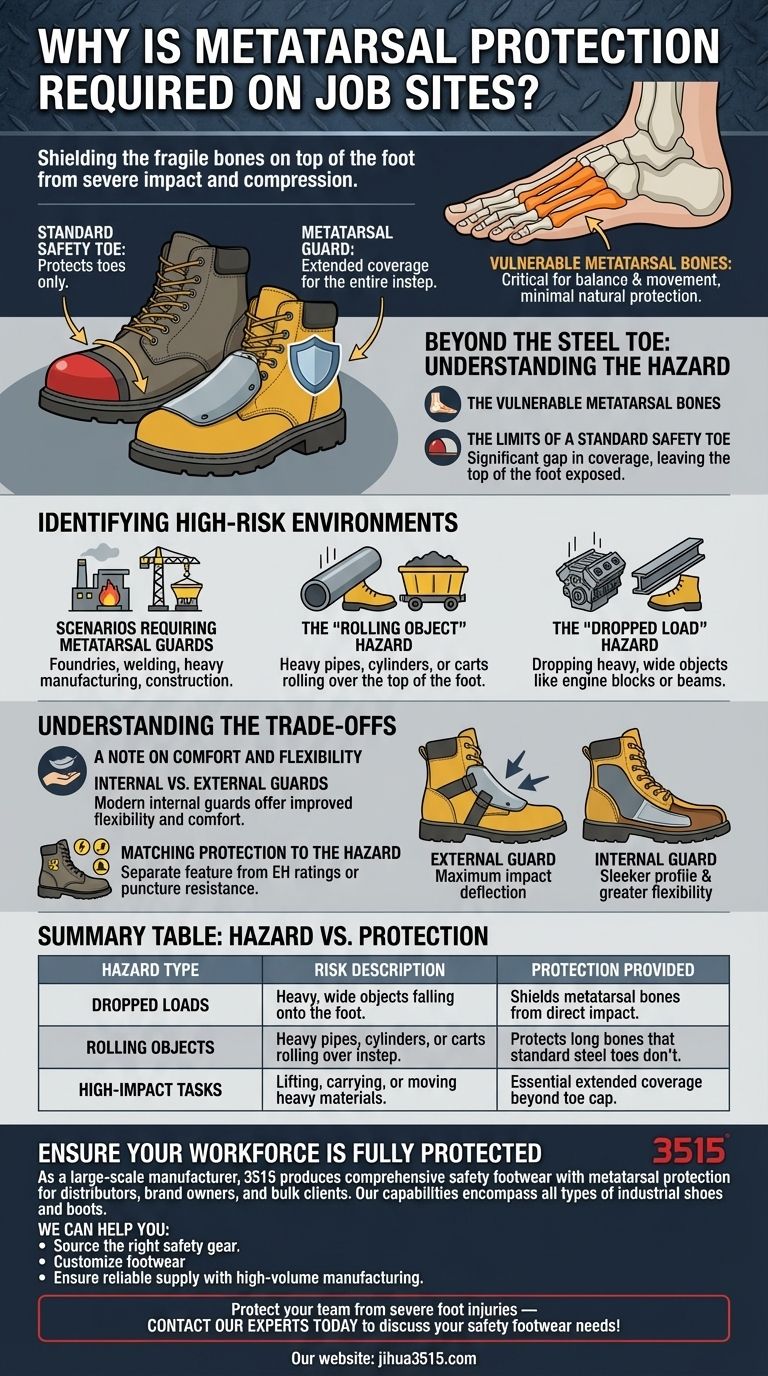

Beyond the Steel Toe: Understanding the Hazard

To grasp why this extra protection is mandated, it’s essential to understand the anatomy of the foot and the precise limits of traditional safety footwear.

The Vulnerable Metatarsal Bones

The metatarsals are the long bones connecting your ankle to your toes. They form the arch and top of your foot.

These bones are critical for balance and movement but have very little natural padding or muscle to protect them from direct impact.

The Limits of a Standard Safety Toe

A standard protective toe cap, whether made of steel, alloy, or composite material, is designed to protect the toes from being crushed.

However, this protective cap ends right where the metatarsal bones begin. This creates a significant gap in coverage, leaving the top of the foot exposed.

Identifying High-Risk Environments

Metatarsal protection isn't a universal requirement; it's mandated based on a specific risk assessment of the work environment. It becomes necessary when the danger is not just a dropped tool but a catastrophic impact.

Scenarios Requiring Metatarsal Guards

Jobs involving the lifting, carrying, or movement of extremely heavy items often require this protection. This includes industries like foundries, welding, heavy manufacturing, and construction where large materials are handled.

The "Rolling Object" Hazard

A primary driver for metatarsal guards is the risk of rolling objects. Think of heavy pipes, steel cylinders, or industrial carts that could roll over the top of the foot, an injury a steel toe would not prevent.

The "Dropped Load" Hazard

This protection is also vital where there's a risk of dropping heavy, wide objects. A falling toolbox might be stopped by a safety toe, but a dropped engine block, concrete slab, or steel beam could easily crush the entire top of the foot.

Understanding the Trade-offs

Like any specialized personal protective equipment (PPE), footwear with metatarsal protection comes with specific considerations.

A Note on Comfort and Flexibility

Historically, external metatarsal guards were seen as rigid and cumbersome. Modern designs, especially internal guards built directly into the boot, offer significantly improved flexibility and comfort without sacrificing safety.

Internal vs. External Guards

Metatarsal guards come in two primary forms. External guards are attached to the outside of the boot and offer maximum impact deflection. Internal guards are built into the boot's construction, offering a sleeker profile and greater flexibility.

Matching Protection to the Hazard

It's critical to remember that metatarsal protection is a specific feature, separate from others like electrical hazard (EH) ratings or puncture resistance. A boot can have one, all, or none of these features depending on its design and intended use.

Making the Right Choice for Your Goal

The requirement for metatarsal protection is a direct response to a hazard assessment. Your specific work environment dictates the necessary level of foot protection.

- If your primary risk is from dropped tools or small objects: Standard safety-toe footwear is often the appropriate baseline for protection.

- If you handle heavy, shifting, or rolling materials like pipes or beams: Metatarsal protection is essential to prevent catastrophic crushing injuries to the top of your foot.

- If you work near live electrical circuits: Your priority must be footwear with a certified Electrical Hazard (EH) rating, which is a feature independent of impact protection.

Ultimately, selecting the right protective footwear begins with a clear understanding of the specific dangers present in your workplace.

Summary Table:

| Hazard Type | Risk Description | Protection Provided by Metatarsal Guard |

|---|---|---|

| Dropped Loads | Heavy, wide objects (e.g., engine blocks, beams) falling onto the foot. | Shields the vulnerable metatarsal bones from direct impact and crushing. |

| Rolling Objects | Heavy pipes, cylinders, or carts rolling over the instep. | Protects the long bones on the top of the foot, which standard steel toes do not cover. |

| High-Impact Tasks | Lifting, carrying, or moving heavy materials in foundries, welding, etc. | Provides essential extended coverage beyond the toe cap to prevent catastrophic injuries. |

Ensure Your Workforce is Fully Protected

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear with metatarsal protection for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial shoes and boots, designed to meet the specific hazards of your industry.

We can help you:

- Source the right safety gear with integrated metatarsal guards for maximum protection and comfort.

- Customize footwear to meet your specific job site requirements and safety standards.

- Ensure reliable supply with our high-volume manufacturing expertise.

Protect your team from severe foot injuries — contact our experts today to discuss your safety footwear needs!

Visual Guide

Related Products

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Why is the ASTM D790 standard used to evaluate the flexural performance of safety shoe toe cap materials? Guide to ASTM D790

- What are the safety advantages of slip-on boots? Quick-Removal & Snag-Free Design for Hazardous Work

- What role do custom-made protective shoes play in the postoperative management of foot and ankle reconstruction?

- What factors contribute to the comfort and durability of safety boots? A Guide to All-Day Protection

- How does comfort factor into selecting work shoes? Ensure Safety and Reduce Fatigue

- What designs are available for oil resistant safety boots? Find the Perfect Fit for Your Industry

- What are the features of security guard safety boots for women vs. men? The Ultimate Guide to Anatomical Fit

- How are the parts of a safety shoe assembled? Discover the Engineered Process for Maximum Protection