The short answer is yes, a hot glue gun can be used to improve shoe traction by applying a thin, textured pattern of glue to the outsole. This creates a raised, grippy surface that increases friction between the shoe and the ground, reducing the risk of slipping on smooth surfaces.

This method is a fast and effective DIY solution for adding temporary grip to shoes with overly smooth soles. However, its success hinges on proper application, and it should be viewed as a short-term fix, not a permanent repair.

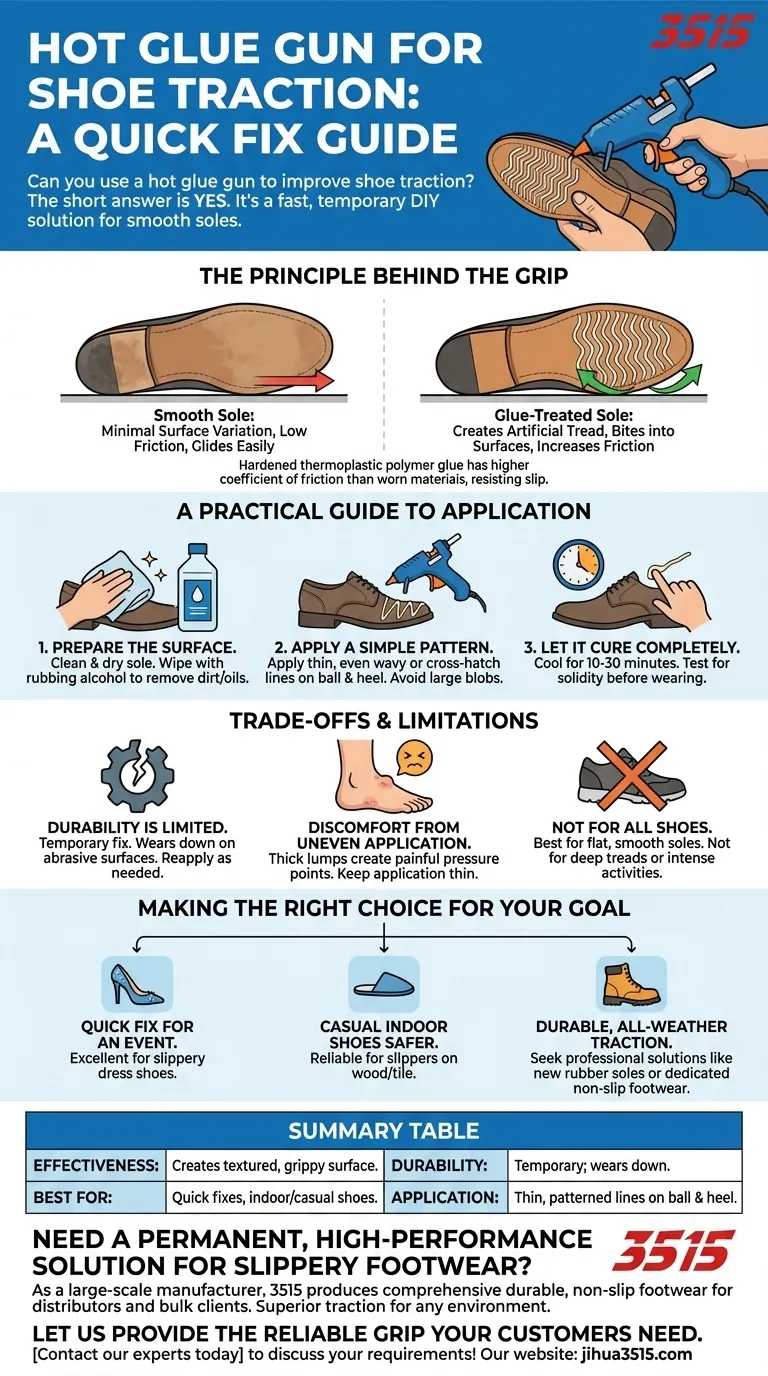

The Principle Behind the Grip

The reason this technique works is based on simple physics. A smooth, worn-out shoe sole has minimal surface variation, allowing it to easily glide over a smooth floor, much like a ski on snow. Adding hot glue fundamentally changes the sole's structure.

Creating a Physical Tread

The hardened glue acts as a new, artificial tread. These raised lines and patterns are able to "bite" into surfaces, creating physical anchor points that resist sliding.

Increasing the Coefficient of Friction

The glue itself, a thermoplastic polymer, often has a higher coefficient of friction than the worn-out material of the sole. This means it naturally resists slipping more effectively.

How Thin Layers Make a Difference

The goal is not to add a thick layer of glue. A thin pattern is sufficient to interrupt the smooth surface of the sole without creating uncomfortable lumps or altering how the shoe fits and feels on your foot.

A Practical Guide to Application

Following a few simple steps ensures the glue adheres properly and provides the best possible traction without causing discomfort.

Step 1: Prepare the Surface

The shoe's outsole must be completely clean and dry. Use a cloth with rubbing alcohol to wipe down the area where you will apply the glue to remove any dirt, oils, or residues that could prevent adhesion.

Step 2: Apply a Simple Pattern

Heat your glue gun until it is ready. Apply the glue in a thin, even pattern on the ball and heel of the shoe. Simple wavy lines, a cross-hatch pattern, or zig-zags are most effective. Avoid large blobs or thick pools of glue.

Step 3: Let it Cure Completely

Allow the glue to cool and harden completely before wearing the shoes. This can take anywhere from 10 to 30 minutes. Test it with your finger to ensure it is solid and no longer tacky to the touch.

Understanding the Trade-offs and Limitations

While effective, this is not a perfect solution. It's critical to understand the limitations before you begin.

Durability is Limited

This is a temporary fix. The hot glue will wear down over time, especially if the shoes are worn frequently on abrasive surfaces like concrete or asphalt. Expect to reapply the glue as needed.

Discomfort from Uneven Application

Applying too much glue or creating thick, lumpy spots will be noticeable when you walk. These pressure points can be uncomfortable or even painful. The key is to keep the application thin and consistent.

Not for All Shoes or Conditions

This method works best on shoes with flat, smooth soles, such as dress shoes or worn-out sneakers. It is not effective for shoes that already have a deep tread or for intense athletic activities where sole integrity is critical.

Making the Right Choice for Your Goal

Use this method when it aligns with your specific need for traction.

- If your primary focus is a quick fix for an event: This is an excellent, low-cost way to add grip to slippery dress shoes for a wedding or indoor party.

- If your primary focus is making casual indoor shoes safer: For slippers or house shoes used on hardwood or tile floors, the hot glue method provides a reliable improvement in safety.

- If your primary focus is durable, all-weather traction: You should seek a professional solution like having a cobbler add a new rubber sole or purchasing dedicated non-slip footwear.

By understanding its purpose as a simple, temporary tool, you can effectively use hot glue to give your slick shoes a new lease on life.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Effectiveness | Creates a textured, grippy surface on smooth soles. |

| Best For | Quick fixes for indoor events or casual shoes. |

| Durability | Temporary; wears down with use on abrasive surfaces. |

| Application | Thin, patterned lines on the ball and heel of the shoe. |

Need a permanent, high-performance solution for slippery footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, non-slip footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots with superior traction for any environment.

Let us provide the reliable grip your customers need. Contact our experts today to discuss your requirements!

Visual Guide

Related Products

- Durable Spiked Camouflage Boots Wholesale & Factory Production

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What activities are non-slip shoes suitable for? Maximize Safety in Any Slippery Environment

- What are the key features to look for in slip-resistant shoes? An Expert's Guide to Workplace Safety

- Why are slip-resistant shoes important in certain work environments? An Expert's Guide to Workplace Safety

- What is the benefit of wearing slip-resistant kitchen shoes? Prevent Costly Slips & Falls in Your Kitchen

- What variety of food service shoes are available for different workplace needs? Match Style to Role for Ultimate Safety & Comfort

- How do athletic shoes with non-slip features differ from regular ones? Discover the Grip Advantage

- What aspects of material and construction should be considered when choosing slip-resistant work shoes? A Guide to Safety and Durability

- Why is friction coefficient testing on wet surfaces essential? Science-Backed Slip Resistance Secrets