-

I started by deconstructing the request. I recognized that the user is a knowledgeable professional, so I need to provide more than just surface-level information. They're looking for an expert, someone who can explain the specifics and help them make an informed decision. My core strategy is to address both the immediate question ("Why are slip-resistant shoes important?") and the underlying question ("What makes a shoe truly slip-resistant, and how do I choose the right one?"). I'm going to adopt an authoritative yet empathetic tone. Short paragraphs, headings, and bolding will be my allies in creating a scannable, reader-friendly guide.

-

Next, I dove into the references. I carefully analyzed each one, noting key points and looking for opportunities to synthesize the information. I had to focus on building a narrative around these points:

- The Problem: I realized that refs 1, 2, and 3 established the core problem—slips, trips, and falls—and where they're most common. This would form the foundation.

- The Solution: Refs 5, 6, 7, and 8 provided the real meat. Ref 5 was key for its breakdown of specific features for different environments. This helps me show that it's not a one-size-fits-all solution. Ref 8 gave me the technical details to explain the how of slip resistance: the tread pattern, material, and groove depth.

- The Context: Ref 9 showed that these shoes contribute to worker productivity and safety by protecting against spills and grease.

- The Holistic View: I also saw I needed to explain that slip-resistance should be considered with other safety features.

-

Finally, I put together the structure of the guide. I'll start with a strong opening that directly addresses the "what". The quote box (the "Core Takeaway Box") will be the guiding theme: engineering. It's not just a shoe; it's a system.

- The "Deep Need" is addressed in a structured way: I'll deconstruct slip resistance from an engineering perspective, followed by a holistic safety system, and ending with a critical section on the nuances and misconceptions. I'll make sure to point out that even "slip-resistant" shoes have their limits, and the most robust safety features may not be the most comfortable in certain situations.

- Finally, I'll end with a clear, actionable list to empower the user to make an informed decision. I'll provide guidelines based on their specific work environment, taking the details from reference 5.

- I'll finish by emphasizing the importance of correctly engineered footwear for safety.

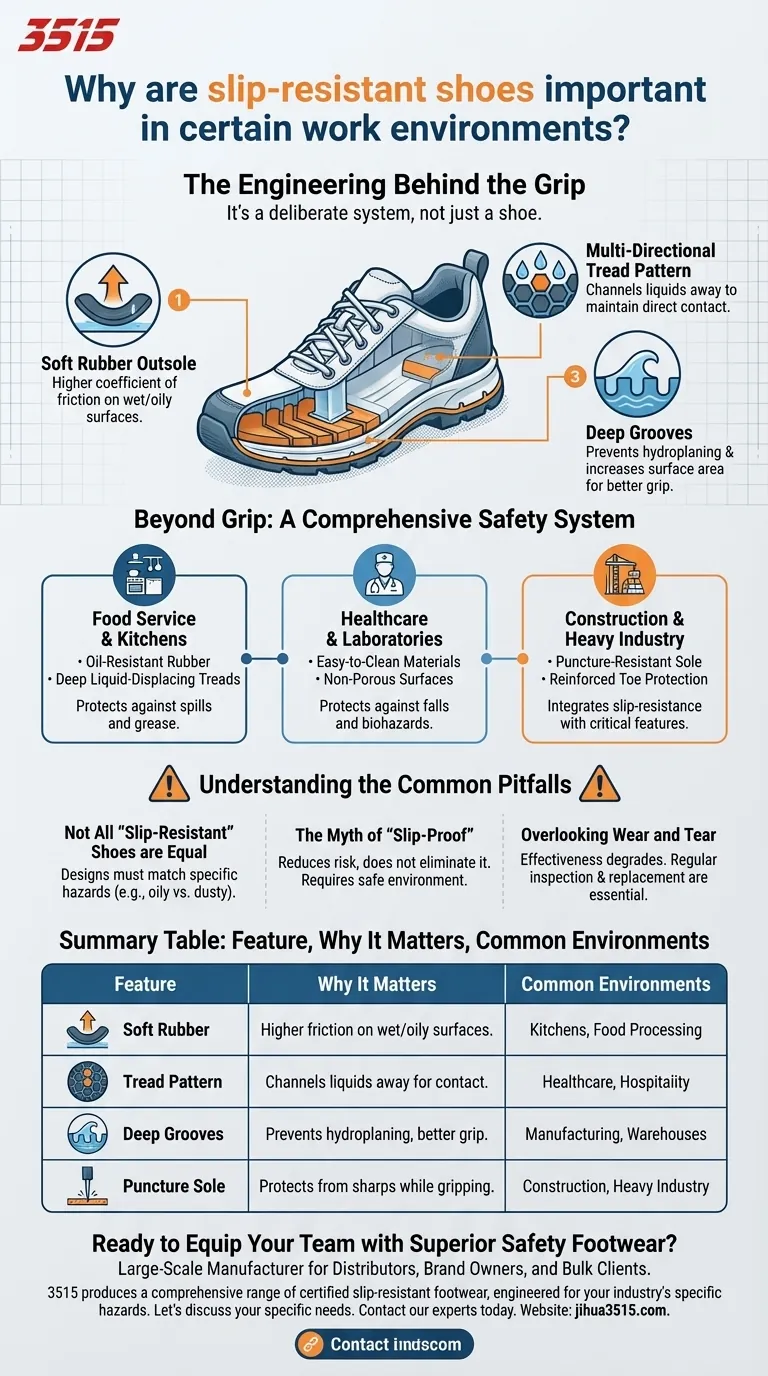

This structure allows me to give the user the complete picture: I'll answer the "why" and, more importantly, the "how," and I will point out the tradeoffs for each of the specific use cases. At its core, slip-resistant shoes are a critical piece of personal protective equipment designed to prevent slips, trips, and falls, which are among the most common causes of workplace injuries. Unlike standard footwear, they are specifically engineered with materials and tread patterns that provide superior traction on wet, oily, or otherwise slick surfaces common in environments like kitchens, hospitals, and manufacturing facilities.

The true value of slip-resistant footwear lies not in a vague promise of "grip," but in its specific engineering. The sole material, tread pattern, and groove depth work as a deliberate system designed to mitigate the precise risks—be it water, oil, or chemicals—of a given work environment.

Deconstructing Slip-Resistance: The Engineering Behind the Grip

To understand why these shoes are so important, you must first understand how they work. Their effectiveness is not accidental; it is the result of intentional design choices that address the physics of traction.

The Role of Outsole Material

The foundation of a slip-resistant shoe is its outsole, which is typically made from softer, high-grade synthetic rubber. This material offers a better coefficient of friction than the harder plastics or leather found on standard shoes, allowing it to better grip smooth, greasy, or wet floors.

Tread Pattern and Liquid Displacement

The shape of the tread is engineered to channel liquids away from the bottom of the shoe. Interlocking patterns, often hexagonal or circular, create pathways for water, oil, and other fluids to disperse, ensuring the sole makes direct contact with the solid ground beneath.

The Physics of Groove Depth

In addition to the pattern's shape, the depth of its grooves is critical. Deeper grooves create more surface area and higher friction, effectively preventing the shoe from hydroplaning on a thin layer of liquid. This design is what maintains a secure hold even when moving quickly across a spill.

Beyond Grip: A Comprehensive Safety System

True workplace safety footwear often integrates slip-resistance with other critical protective features. This turns a simple shoe into a comprehensive tool designed for a specific professional environment.

Environment-Specific Protection

Different jobs have different hazards. A construction boot needs a puncture-resistant sole and a steel toe, while a shoe for a lab requires chemical resistance and materials that are easy to clean and sterilize. The "slip-resistant" feature is the baseline, not the entire package.

Enhanced Durability

Workplace shoes are built to withstand heavy-duty tasks and unpredictable conditions. They use reinforced materials, sturdy construction, and often feature protected toes to endure the rigors of a demanding job far longer than everyday footwear could.

Understanding the Common Pitfalls

Choosing the right shoe requires looking past the marketing label. A failure to understand the nuances can lead to a false sense of security.

Not All "Slip-Resistant" Shoes are Equal

The term "slip-resistant" is not a universal standard. A shoe designed to grip an oily kitchen floor may not perform well on a dusty construction site or a polished hospital corridor. The design must match the specific hazard.

The Myth of "Slip-Proof"

No shoe can make you "slip-proof." Slip-resistant footwear is designed to drastically reduce the risk of a fall, but it cannot eliminate it entirely. It is one component of a safe workplace, which must also include clean floors and cautious movement.

Overlooking Wear and Tear

The effectiveness of a slip-resistant sole degrades over time. As the specialized tread wears down, its ability to displace liquid and maintain grip diminishes. Regular inspection and timely replacement of work shoes are essential for continued safety.

Making the Right Choice for Your Goal

To select the appropriate footwear, you must match the shoe's engineering to your specific workplace environment and its inherent risks.

- If your primary focus is food service or kitchens: Prioritize a shoe with deep, liquid-displacing treads and a sole made from oil-resistant rubber compound.

- If your primary focus is healthcare or laboratories: Choose footwear that combines certified slip-resistance with easy-to-clean, non-porous materials to protect against both falls and biohazards.

- If your primary focus is construction or heavy industry: You need a boot that integrates slip-resistance with critical features like puncture-proof soles and reinforced toe protection.

Investing in correctly engineered footwear is a foundational step in ensuring your safety and maintaining your focus at work.

Summary Table:

| Feature | Why It Matters | Common Environments |

|---|---|---|

| Soft Rubber Outsole | Provides a higher coefficient of friction on wet, oily surfaces. | Kitchens, Food Processing |

| Multi-Directional Tread Pattern | Channels liquids away to maintain direct contact with the floor. | Healthcare, Hospitality |

| Deep Grooves | Prevents hydroplaning and increases surface area for better grip. | Manufacturing, Warehouses |

| Puncture-Resistant Sole | Protects feet from sharp objects while maintaining slip resistance. | Construction, Heavy Industry |

Ready to Equip Your Team with Superior Safety Footwear?

As a leading large-scale manufacturer, 3515 produces a comprehensive range of certified slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the specific hazards of your industry in mind.

We provide durable, reliable footwear that protects your workforce, reduces injury-related downtime, and demonstrates your commitment to safety.

Let's discuss your specific needs. Contact our experts today for a consultation on the right footwear solution for your business.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- How is puncture resistance evaluated in footwear soles? Balance Protection, Comfort & Safety

- What does a green triangle symbol on safety footwear mean? Your Guide to Maximum Puncture & Impact Protection

- What materials are used in the construction of these boots? A Guide to Velour Leather, Textile & PU Soles

- Why is slip resistance important in safety footwear? Prevent Costly Workplace Slips and Falls

- What do the markings on ASTM-compliant safety shoes indicate? Decode the Safety Labels for Maximum Protection