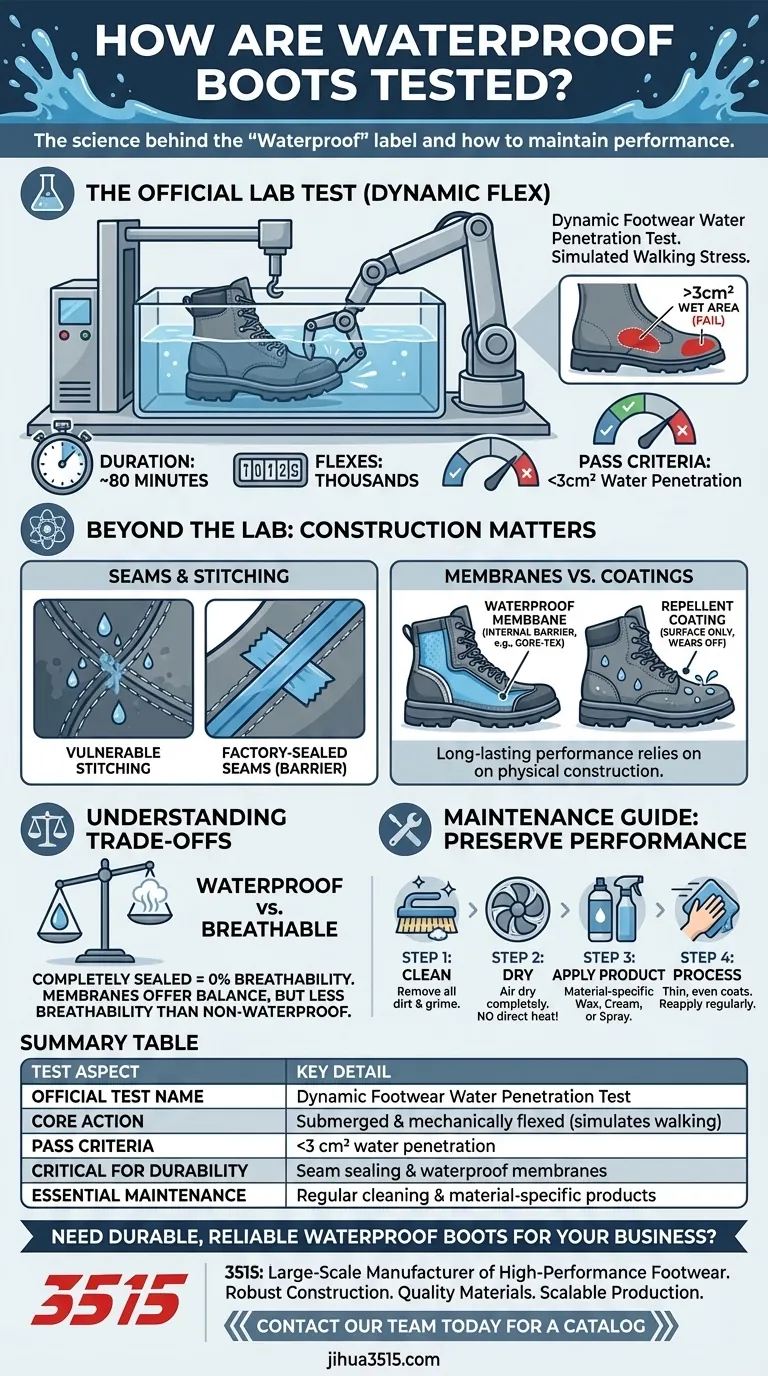

To be certified as waterproof, boots undergo a standardized "Dynamic Footwear Water Penetration Test," often called the water flex test. In this lab procedure, a boot is submerged in water at a specific angle and then mechanically flexed thousands of times to simulate the stress of walking. The boot passes and earns the "waterproof" label only if less than 3 square centimeters of water penetrates the interior after a set duration, typically 80 minutes.

The official waterproof test is a rigorous mechanical simulation, but true, long-lasting performance in the real world depends just as much on the boot's physical construction and your commitment to proper maintenance.

What "Waterproof" Means in a Lab Setting

To understand the promise of a waterproof boot, you must first understand how that promise is verified. The process is a highly controlled mechanical test, not a simple dunk in a bucket.

The Dynamic Flex Test

The core of the certification is a machine that mimics the motion of a foot walking. The boot is securely placed, submerged in water to a specific depth, and then the machine repeatedly bends the forefoot, simulating thousands of steps.

The Pass/Fail Criteria

This is not a subjective evaluation. The test is precise: after the flexing cycle is complete, the inside of the boot is checked for moisture. If the total wet area is less than 3cm², the boot is considered waterproof. If it exceeds this threshold, it fails.

Simulating Real-World Stress

The flexing motion is the critical part of the test. Water is most likely to penetrate a boot when the materials are stressed, bent, and creased during movement. This test is specifically designed to identify weaknesses that only appear under the strain of active use.

Beyond the Lab: Construction and Materials

A passing grade in the lab is a good start, but the boot's design and materials dictate how long that waterproof performance will last.

The Critical Role of Seams

Stitching is the natural enemy of a waterproof design. Every needle hole is a potential entry point for water. The most reliable waterproof boots feature minimal stitching and factory-sealed seams, where a waterproof tape is bonded over the stitching on the inside to create a complete barrier.

Waterproof Membranes vs. Repellent Coatings

A key distinction is how the boot achieves its waterproofness. Some rely solely on external treatments like waxes or sprays, which create a water-repellent surface. These treatments are effective but require regular reapplication as they wear off.

Higher-performance boots use a dedicated waterproof membrane (like a Gore-Tex bootie) as an internal layer. This barrier provides a more durable and reliable line of defense, independent of the external surface treatment.

Understanding the Trade-offs

No single boot design is perfect for every situation. Understanding the inherent compromises in waterproof footwear helps you manage your expectations and make better choices.

Waterproof vs. Breathable

The ultimate trade-off is between keeping water out and letting sweat vapor escape. A completely sealed rubber boot is 100% waterproof but has zero breathability. High-tech boots with membranes attempt to balance both, but a highly waterproof boot will almost always be less breathable than a non-waterproof alternative.

The Limits of Testing

A lab test simulates a specific condition for a limited time. It cannot replicate every real-world scenario, such as full submersion for an extended period, the grinding effect of trail debris, or the gradual degradation of materials over years of use.

Why Waterproofing Fails Over Time

Surface treatments inevitably wear off with abrasion and flexing. Waterproof membranes can be punctured by debris or break down after thousands of flexes. This is why maintenance is not optional—it's essential for preserving performance.

How to Maintain Your Boots' Waterproofing

You can replicate the core principles of waterproofing at home to maintain and restore your boots' performance. The process is simple but must be done correctly.

Step 1: Thorough Cleaning

You cannot waterproof a dirty boot. Dirt and grime hold moisture against the material and abrade surface coatings. Use a stiff brush to remove all dried debris, then clean with a rag and a simple soap-and-water solution if needed.

Step 2: Proper Drying

Allow the boots to dry completely and naturally in a well-ventilated area. Never use a direct heat source like a radiator or campfire, as intense heat can damage adhesives and cause leather to crack. A fan can safely speed up the process.

Step 3: Applying the Right Product

The product you use depends entirely on the boot's material.

- Waxes, creams, or oils are best for smooth leather boots.

- Waterproof sprays are necessary for suede, nubuck, and fabric boots, as heavier treatments can ruin their texture.

- Seam sealants can be applied directly to the stitching for an extra layer of protection before the main treatment.

Step 4: The Application Process

Read your product's instructions. Generally, you'll apply a thin, even coat to all exterior surfaces with a clean rag, paying special attention to seams, eyelets, and the tongue. Let it absorb, apply a second coat if needed, and then buff off any excess.

Making the Right Choice for Your Needs

- If your primary focus is guaranteed dryness for extreme conditions: Look for boots with a waterproof membrane liner (like Gore-Tex) and minimal, factory-sealed seams.

- If your primary focus is maintaining existing boots: Commit to a routine of cleaning them after use and reapplying a waterproofing product specifically designed for their material.

- If your primary focus is evaluating a new purchase: Understand the "waterproof" label signifies passing a specific mechanical test, but long-term performance will depend on construction and your care.

Understanding how boots are tested and maintained empowers you to choose the right gear and keep it performing at its best.

Summary Table:

| Test Aspect | Key Detail |

|---|---|

| Official Test Name | Dynamic Footwear Water Penetration Test (Water Flex Test) |

| Core Action | Boot is submerged and mechanically flexed to simulate walking |

| Pass/Fail Criteria | Less than 3 cm² of water penetration after testing |

| Critical for Durability | Seam sealing and use of waterproof membranes (e.g., Gore-Tex) |

| Essential Maintenance | Regular cleaning and application of material-specific waterproofing products |

Need Durable, Reliable Waterproof Boots for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance waterproof footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, built to pass rigorous standards and deliver long-lasting customer satisfaction.

We ensure durability and performance by focusing on:

- Robust Construction: Utilizing advanced sealing techniques and premium waterproof membranes.

- Quality Materials: Sourcing materials designed to withstand the demands of the official flex test and real-world use.

- Scalable Production: Delivering consistent quality and reliability for large-volume orders.

Let's discuss how we can meet your specific needs. Contact our team today to request a catalog or discuss your next project.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How do professional safety shoes provide protection in automotive workshop environments? Essential PPE for Workshop Safety

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection

- What does safe footwear mean? The Ultimate Guide to Choosing the Right PPE for Your Job

- What specific protective functions do safety shoes offer during high-risk tasks? Master Safety on Structural Beams