At its core, safe footwear is personal protective equipment (PPE) specifically engineered to protect your feet from predictable workplace hazards. It goes far beyond a simple sturdy boot by incorporating specific protective features designed to prevent common injuries caused by impact, compression, and punctures. The selection of appropriate footwear is always dictated by the specific risks present in your environment.

True "safe footwear" is not a one-size-fits-all solution. It is a system of protection where the boot or shoe has been tested and certified to meet specific performance standards against the unique hazards of your job.

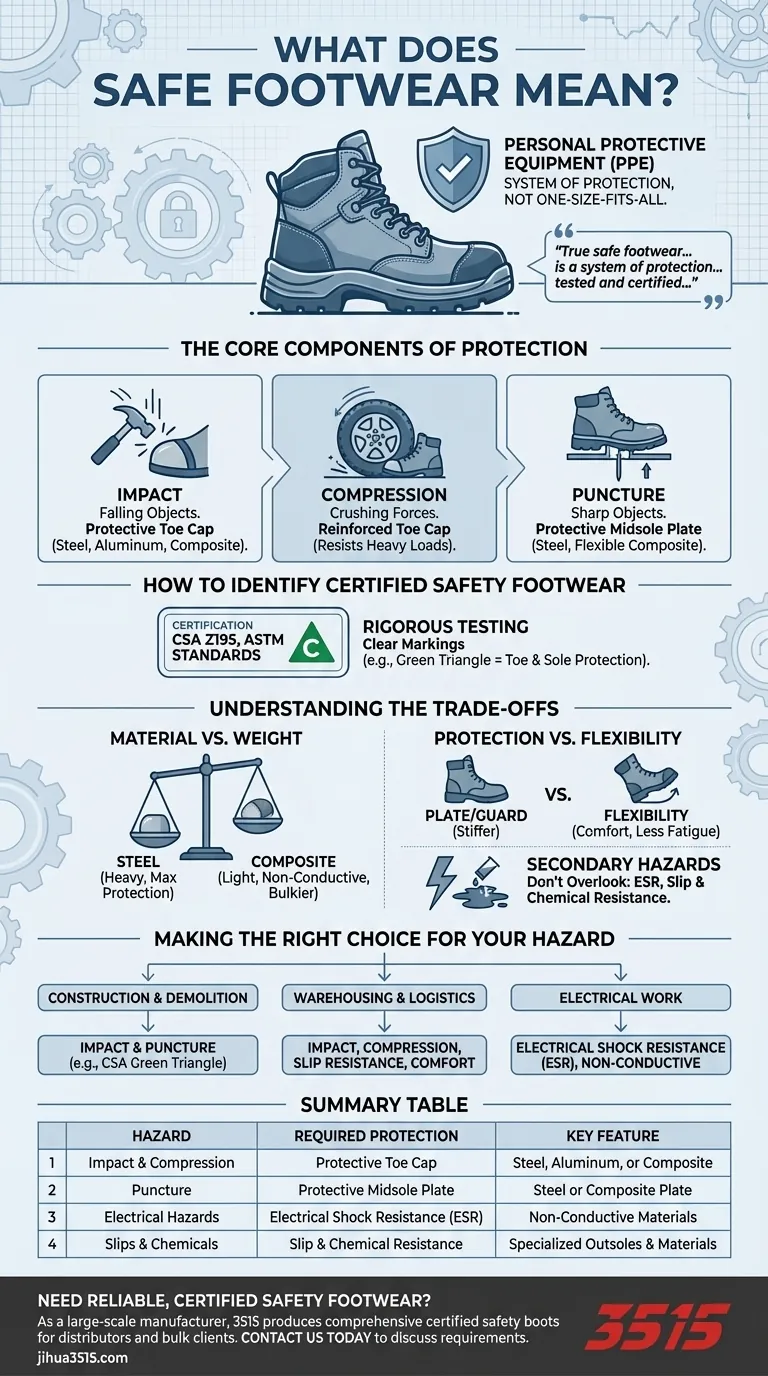

The Core Components of Protection

Understanding what makes footwear "safe" begins with understanding the primary threats it is designed to counter. These are the foundational elements of protection you will find in most certified safety footwear.

Protection Against Impact

This feature guards against injuries from falling objects. A protective toe cap, often made of steel, aluminum, or composite materials, is built into the front of the footwear to withstand a heavy, direct blow.

Protection Against Compression

This protects your feet from being crushed under a heavy rolling or stationary object, such as a vehicle tire or a pallet jack. The same protective toe cap that resists impact is also engineered to resist compressive forces.

Protection Against Puncture

This feature is critical when working around sharp objects like nails, scrap metal, or glass. A protective plate, made of steel or flexible composite material, is positioned in the midsole to prevent these items from piercing the sole and injuring your foot.

How to Identify Certified Safety Footwear

Simply looking "tough" is not enough. Authentic safety footwear is certified to meet specific regional and national standards, providing a guarantee of its protective capabilities.

The Role of Standards

Standards like CSA Standard Z195 in Canada or ASTM standards in the US are crucial. They ensure that the footwear has undergone rigorous, standardized testing for all its claimed safety features.

Reading the Markings

Certified footwear uses a system of clear markings, often on the tongue or side of the boot. For example, under the CSA system, a green triangle indicates protection for both the toe and the sole (puncture resistance), which is the most common standard for construction sites.

Understanding the Trade-offs

Choosing the right footwear involves balancing protection with other factors. An incorrect choice can lead to discomfort, non-compliance, or even new hazards.

Material vs. Weight

Traditional steel toes and plates offer maximum protection but add significant weight. Modern composite materials are much lighter, don't conduct cold, and won't set off metal detectors, but can sometimes be bulkier to achieve the same strength rating.

Protection vs. Flexibility

Features like puncture-resistant plates and metatarsal guards (which protect the top of the foot) inherently make footwear stiffer. While essential for high-risk areas, this reduced flexibility can cause fatigue over long periods in less hazardous environments.

Forgetting Secondary Hazards

Focusing only on impact and puncture can cause you to overlook other critical risks. A boot with a steel toe is not automatically suitable for an electrician, who needs Electrical Shock Resistance (ESR). Likewise, someone working with liquids needs slip and chemical resistance.

Making the Right Choice for Your Hazard

Your specific work environment is the only guide that matters. Use your workplace hazard assessment to determine the primary risks you face.

- If your primary focus is construction or demolition: You need footwear certified for impact and puncture protection (e.g., CSA Green Triangle).

- If your primary focus is warehousing or logistics: You need impact and compression resistance, but also prioritize excellent slip resistance and comfort for long hours on concrete.

- If your primary focus is electrical work: You must have footwear specifically rated for Electrical Shock Resistance (ESR) and ensure it has no conductive materials.

Ultimately, safe footwear is the correct footwear for the specific hazard you face.

Summary Table:

| Hazard | Required Protection | Key Feature |

|---|---|---|

| Impact & Compression | Protective Toe Cap | Steel, Aluminum, or Composite |

| Puncture | Protective Midsole Plate | Steel or Composite Plate |

| Electrical Hazards | Electrical Shock Resistance (ESR) | Non-Conductive Materials |

| Slips & Chemicals | Slip & Chemical Resistance | Specialized Outsoles & Materials |

Need reliable, certified safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. We ensure every pair meets rigorous standards for impact, puncture, and other specific hazards, combining protection with durability and comfort.

Contact us today to discuss your requirements and get a quote tailored to your needs.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Why is specialized personal protective equipment required for specific industries? Enhancing Safety in Heavy Industry

- What are the benefits of steel toe caps in work boots? Achieve Maximum Protection for Heavy-Duty Work

- What safety standards does the 11-inch waterproof pull-on boot meet? ASTM-Certified Protection for Industrial Work

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- How do safety features in work boots contribute to overall comfort and safety? Unlock the Secret to All-Day Protection