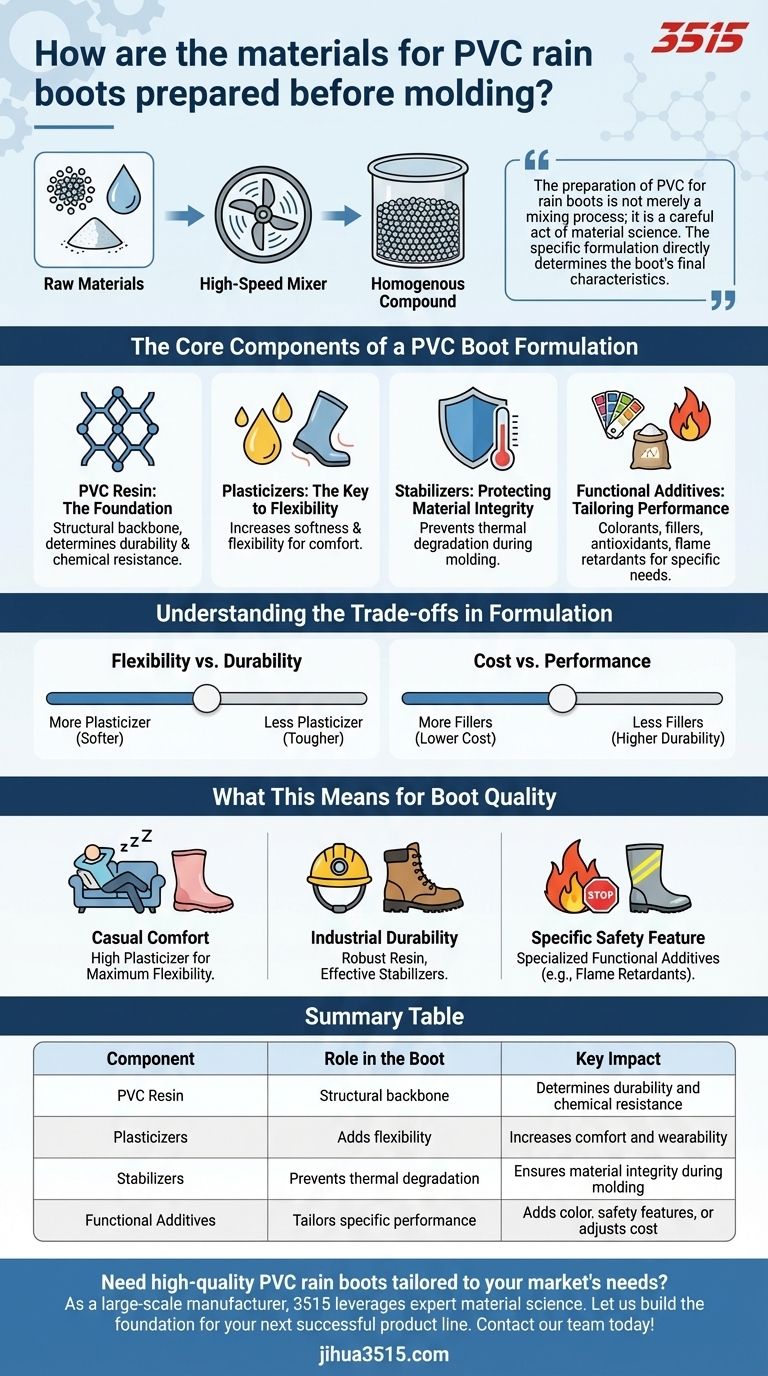

Before molding, the raw materials for PVC rain boots are precisely weighed and then combined in a high-speed mixer. This critical step ensures all ingredients, from the base resin to specialized additives, are thoroughly and evenly blended into a homogenous compound, which is essential for consistent quality in the final product.

The preparation of PVC for rain boots is not merely a mixing process; it is a careful act of material science. The specific formulation of ingredients directly determines the boot's final characteristics, including its flexibility, durability, and resistance to environmental factors.

The Core Components of a PVC Boot Formulation

The quality of a PVC rain boot is decided long before it takes shape in a mold. It begins with the precise combination of several key ingredients, each serving a distinct purpose.

PVC Resin: The Foundation

Polyvinyl chloride (PVC) resin is the structural backbone of the boot. The grade of resin selected dictates the footwear's fundamental properties, such as its overall durability and resistance to chemicals and abrasion.

Plasticizers: The Key to Flexibility

By itself, PVC is a rigid material. Plasticizers are oily substances added to the mixture to increase softness and flexibility, transforming the stiff polymer into a compound that is comfortable to wear.

Stabilizers: Protecting Material Integrity

The process of heating and molding PVC can cause it to decompose. Stabilizers are crucial additives that prevent this thermal degradation, ensuring the material maintains its structural integrity and intended properties throughout manufacturing.

Functional Additives: Tailoring Performance

Beyond the core components, a range of other additives can be included to meet specific requirements. These include colorants for aesthetics, fillers to adjust density and cost, antioxidants for longevity, and flame retardants for safety applications.

Understanding the Trade-offs in Formulation

Creating the ideal PVC compound involves balancing competing priorities. The decisions made during this preparation stage directly impact the final product's performance and cost.

Flexibility vs. Durability

Increasing the amount of plasticizer results in a softer, more comfortable boot. However, an excessively high ratio can compromise the material's tensile strength and abrasion resistance, making it less durable over time.

Cost vs. Performance

Manufacturers can reduce costs by using certain types of fillers. While this can be effective, over-reliance on lower-cost fillers may negatively impact the boot's long-term durability, chemical resistance, and overall lifespan. The highest-quality formulations prioritize performance ingredients over simple cost-cutting measures.

What This Means for Boot Quality

Understanding the material preparation allows you to better assess the quality and purpose of the final product.

- If your primary focus is comfort for casual use: The formulation likely prioritizes a higher ratio of quality plasticizers for maximum flexibility.

- If your primary focus is industrial durability: The compound will emphasize a robust grade of PVC resin and effective stabilizers, creating a tougher, more resilient boot.

- If your primary focus is a specific safety feature: The key lies in the presence of specialized functional additives, such as flame retardants or anti-static agents.

Ultimately, the careful and precise preparation of the PVC compound is the unseen foundation upon which the boot's performance is built.

Summary Table:

| Component | Role in the Boot | Key Impact |

|---|---|---|

| PVC Resin | Structural backbone | Determines durability and chemical resistance |

| Plasticizers | Adds flexibility | Increases comfort and wearability |

| Stabilizers | Prevents thermal degradation | Ensures material integrity during molding |

| Functional Additives | Tailors specific performance | Adds color, safety features, or adjusts cost |

Need high-quality PVC rain boots tailored to your market's needs? As a large-scale manufacturer, 3515 leverages expert material science to formulate the perfect balance of flexibility, durability, and cost-effectiveness for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of footwear. Let us build the foundation for your next successful product line. Contact our team today to discuss your requirements!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What is the significance of understanding the materials used in wellington boots? Choose the Right Boot for Your Needs

- What material are PVC boots made from? A Guide to Their Pros, Cons & Best Uses

- What are the benefits of wearing gumboots for protection? Essential Safety for Hazardous Environments

- Why are wellies a good footwear choice for children in cold and wet weather? Ultimate Protection for Active Play

- How were Wellington boots used in World War II? Essential Gear for Wet Battlefields

- What activities are Wellington boots suitable for? A Guide to Dry Feet in Any Environment

- What are the benefits and drawbacks of neoprene-lined wellington boots? A Guide to Cold-Weather Footwear

- What are some user-recommended brands and models for waterproof footwear? Find Your Perfect Fit for Any Activity