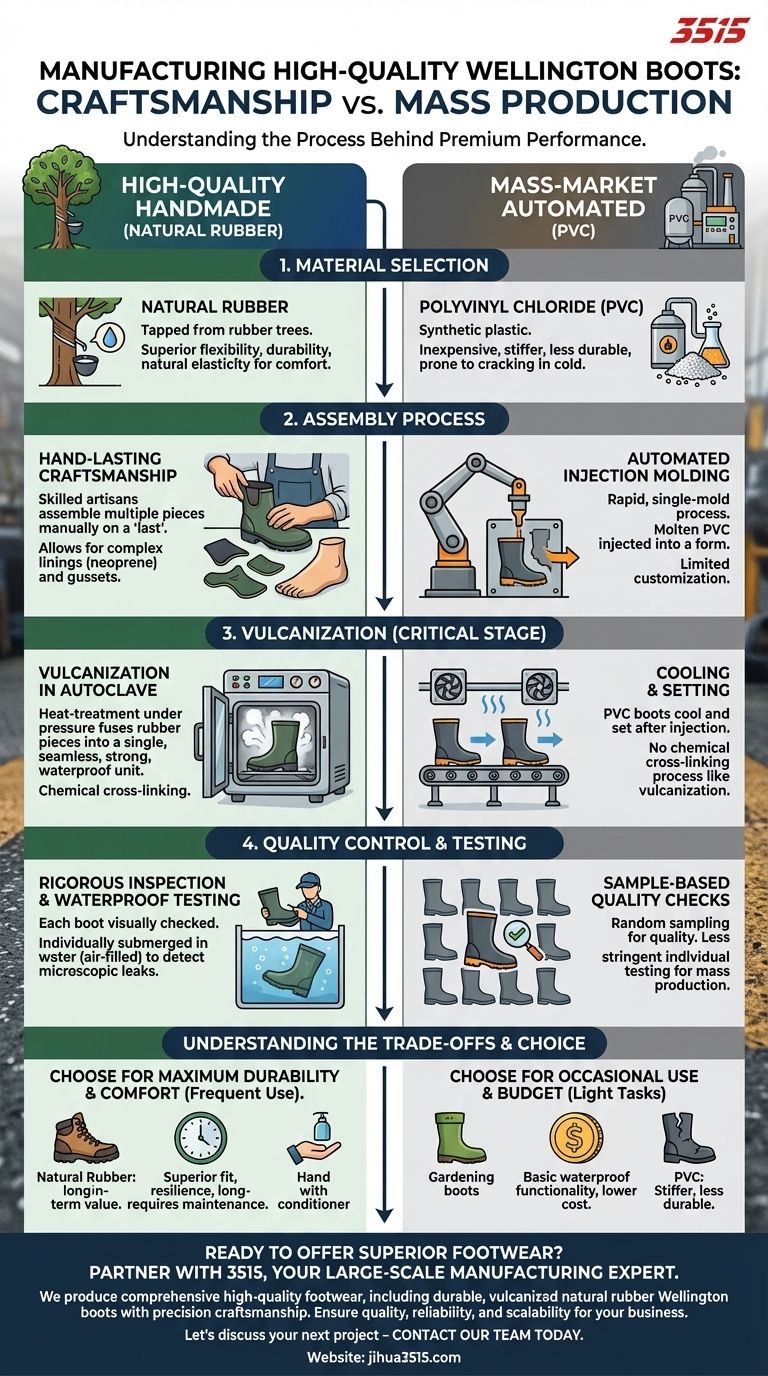

In short, high-quality Wellington boots are handmade. The process centers on manually assembling multiple pieces of natural rubber onto a boot-shaped form, a method fundamentally different from the single-mold injection process used for cheaper synthetic alternatives. This labor-intensive technique is followed by a heat-treatment process called vulcanization, which fuses the rubber pieces into a single, seamless, and waterproof unit.

The core difference in high-quality boot manufacturing lies in its use of natural rubber and a meticulous, multi-stage assembly process. This manual craftsmanship results in superior flexibility, durability, and comfort compared to mass-produced PVC boots.

The Foundation: Material Selection

The choice of material is the first and most critical distinction in Wellington boot manufacturing. It dictates the entire production process and the final quality of the boot.

Why Natural Rubber?

High-end boots are almost exclusively made from natural rubber. This material is tapped from rubber trees and is prized for its inherent flexibility, durability, and superior waterproof properties.

Its natural elasticity allows the boot to move with your foot, providing significantly more comfort over long periods of wear.

The PVC Alternative

Mass-market boots are typically made from polyvinyl chloride (PVC), a synthetic plastic. PVC is inexpensive and lends itself to a rapid, automated manufacturing method called injection molding.

While waterproof, PVC is much stiffer, less durable, and more prone to cracking in cold temperatures than natural rubber.

The Handmade Assembly Process

The "handmade" label on premium boots refers to a specific, skilled process known as hand-lasting, where the boot is built piece by piece.

Design and Pattern Cutting

The process begins with a design that considers ergonomics, traction, and fit. Patterns for each section of the boot—the sole, heel, upper, and reinforcements—are then cut from large sheets of natural rubber.

Hand-Lasting the Components

Skilled artisans then assemble these cut pieces around a three-dimensional foot model called a last. Each piece is carefully placed and bonded, gradually building the boot's shape. This manual assembly allows for the inclusion of complex features like linings and gussets.

Adding Linings and Support

During assembly, materials like neoprene are often added as a lining for insulation and comfort. Extra layers of rubber are also applied to high-wear areas like the heel, toe, and shin for added protection and structural integrity.

The Critical Vulcanization Stage

Once fully assembled, the "green" rubber boot is placed in a large, high-pressure oven called an autoclave. The boot is heated under pressure, which triggers vulcanization—a chemical process that cross-links the rubber molecules.

This crucial step fuses all the individual rubber pieces into a single, seamless, and incredibly strong waterproof shell.

Understanding the Trade-offs

Choosing a high-quality, handmade boot involves recognizing the inherent trade-offs in its materials and construction.

Cost and Labor

The multi-stage, manual assembly process is far more time-consuming and requires more skilled labor than automated injection molding. This craftsmanship is the primary driver of the higher cost.

Durability vs. Maintenance

Natural rubber is exceptionally durable but is not indestructible. Over time, it can be susceptible to degradation from UV light and ozone. This is why high-quality boots require occasional treatment with a rubber conditioner to maintain their flexibility and prevent cracking.

Quality Control: The Final Hurdle

The final stages of manufacturing are dedicated to ensuring every boot meets exacting standards before it leaves the factory.

Rigorous Inspection

After vulcanization, every boot is visually inspected by quality control experts. They check for any imperfections in the rubber, seams, or lining that could compromise performance or longevity.

Waterproof Testing

Most importantly, each boot is individually tested to guarantee it is 100% waterproof. This often involves filling the boot with air and submerging it in water to look for any escaping bubbles, ensuring there are no microscopic leaks.

What This Means for Your Choice

Understanding the manufacturing process allows you to select a boot based on your actual needs and priorities.

- If your primary focus is maximum durability and comfort for frequent use: Choose a hand-lasted, vulcanized natural rubber boot for its superior fit and resilience.

- If your primary focus is occasional use, light tasks, or a lower budget: A mass-produced PVC boot can provide basic waterproof functionality.

Recognizing the craftsmanship behind a handmade boot allows you to appreciate the value in its design, performance, and longevity.

Summary Table:

| Key Manufacturing Step | Description | Key Material |

|---|---|---|

| Material Selection | High-quality boots use natural rubber for flexibility and durability. | Natural Rubber |

| Hand-Lasting | Skilled artisans assemble rubber pieces by hand on a foot-shaped last. | Cut Rubber Pieces |

| Vulcanization | Boots are heat-treated in an autoclave to fuse pieces into a seamless shell. | N/A |

| Quality Control | Each boot undergoes rigorous inspection and waterproof testing. | N/A |

Ready to Offer Superior Footwear? Partner with 3515, Your Large-Scale Manufacturing Expert.

As a leading manufacturer, 3515 produces a comprehensive range of high-quality footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including durable, vulcanized natural rubber Wellington boots built with precision craftsmanship.

We ensure exceptional quality, reliability, and scalability for your business needs. Let's discuss your next project – contact our team today to get started!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Is it advisable to buy second-hand wellies for children? Protect Your Child's Foot Health & Development

- How should wellies fit around the calf and foot? Achieve All-Day Comfort and Security

- What factors should be considered when selecting waterproof snow boots for men? A Technical Guide

- How can wellies help keep kids' feet warm in cold weather? The Science of Dry, Warm Feet

- What factors should be considered when choosing wellington boots for different activities? A Guide to Material, Support, and Endurance

- How effective are rubber or slip-on boots in winter? The Surprising Truth About Warmth & Safety

- Do Wellington boots require a breaking-in period? No, but here's how to ensure immediate comfort.

- What are the key considerations when selecting women's wellies? A Guide to Choosing the Perfect Pair