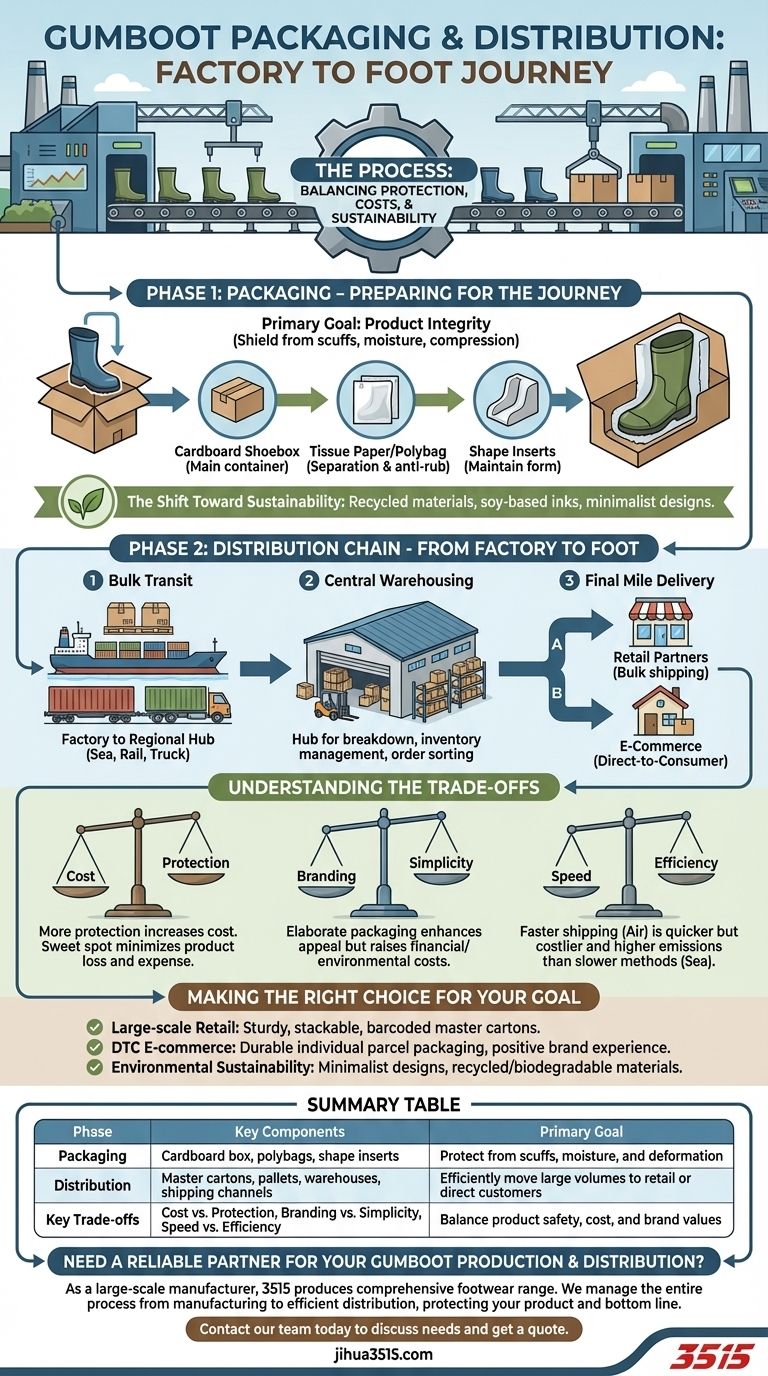

To get gumboots from the factory to the customer, they are first packaged in materials designed to protect them from scuffs, moisture, and compression. This packaging, which increasingly prioritizes sustainability, prepares the boots for distribution through a logistics network of warehouses, retail partners, and direct-to-consumer shipping channels.

The entire process is a carefully managed system designed to balance three critical factors: protecting the product, managing logistical costs, and meeting modern demands for brand presentation and environmental responsibility.

The Packaging Phase: Preparing for the Journey

The primary role of packaging is to ensure the gumboots arrive in the same condition they left the factory. This involves multiple layers of protection and branding.

Primary Goal: Product Integrity

The packaging must shield the boots from common hazards during shipping and storage. This includes preventing scratches, crushing that can deform the rubber, and damage from moisture.

Common Packaging Components

A typical gumboot package includes a sturdy cardboard shoebox as the main container. Inside, each boot is often separated by tissue paper or placed in a thin polybag to prevent rubbing, with cardboard or plastic inserts used to maintain the boot's shape.

The Shift Toward Sustainability

Modern packaging strategies heavily emphasize environmental impact. Brands are increasingly moving to recycled and recyclable cardboard, using soy-based inks for printing, and adopting minimalist designs that reduce overall material waste without compromising protection.

The Distribution Chain: From Factory to Foot

Once packaged, gumboots enter a multi-step distribution chain designed for efficiency. This process moves large volumes from a central point to various sale locations.

Step 1: Bulk Transit

Individual shoeboxes are packed into large master cartons. These cartons are then loaded onto pallets for cost-effective freight shipping via sea, rail, or truck from the manufacturing facility to a regional distribution center.

Step 2: Central Warehousing

Distribution centers or warehouses act as the central hub. Here, bulk shipments are broken down, inventory is managed, and orders are sorted for different destinations.

Step 3: Final Mile Delivery

From the warehouse, the gumboots complete their journey. Orders are either shipped in bulk to brick-and-mortar retail stores or sent directly to individual customers who ordered online through e-commerce fulfillment.

Understanding the Trade-offs

Choosing the right packaging and distribution strategy involves balancing competing priorities. Making a decision in one area almost always impacts another.

Cost vs. Protection

More robust, multi-layered packaging offers better protection against damage but increases material and shipping costs. Companies must find the sweet spot that minimizes product loss without making the final price uncompetitive.

Branding vs. Simplicity

Elaborate packaging with high-quality printing can enhance a brand's visual appeal and create a positive unboxing experience. However, this often comes at a higher financial and environmental cost compared to simpler, more sustainable options.

Speed vs. Efficiency

Faster shipping methods, like air freight, get products to market quickly but are significantly more expensive and have a larger carbon footprint than slower methods like sea freight. The choice depends on market demand, product launch timelines, and budget.

Making the Right Choice for Your Goal

Your optimal strategy depends entirely on your business model and brand priorities.

- If your primary focus is large-scale retail: Prioritize sturdy, stackable, and barcoded master cartons for efficient warehousing and handling by retail partners.

- If your primary focus is direct-to-consumer e-commerce: Invest in durable packaging that can withstand individual parcel handling while still offering a positive brand experience upon opening.

- If your primary focus is environmental sustainability: Implement minimalist designs using recycled and fully biodegradable materials throughout your entire supply chain.

Ultimately, a thoughtful packaging and distribution strategy is essential for protecting your product, your brand reputation, and your bottom line.

Summary Table:

| Phase | Key Components | Primary Goal |

|---|---|---|

| Packaging | Cardboard box, polybags, shape inserts | Protect from scuffs, moisture, and deformation |

| Distribution | Master cartons, pallets, warehouses, shipping channels | Efficiently move large volumes to retail or direct customers |

| Key Trade-offs | Cost vs. Protection, Branding vs. Simplicity, Speed vs. Efficiency | Balance product safety, cost, and brand values |

Need a reliable partner for your gumboot production and distribution?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear, including gumboots, for distributors, brand owners, and bulk clients. We manage the entire process—from manufacturing with our extensive capabilities to ensuring your products are packaged correctly and distributed efficiently—helping you protect your product and your bottom line.

Contact our team today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- What are the advantages of PVC wellington boots? Discover the Perfect Blend of Affordability & Waterproofing

- How long do Wellington boots typically last with proper care? Maximize Your Boot's Lifespan

- Are wellies suitable for long walks or hiking? Avoid Blisters and Choose the Right Footwear

- What factors should be considered when choosing wellies for dog walking? Find the Perfect Fit for Comfort and Safety

- What are the advantages of natural rubber wellington boots? Superior Durability & Eco-Friendly Performance

- What makes gumboots versatile? From Work Sites to City Streets

- What advantages do duck snow boots provide for men in winter? Stay Dry, Warm, and Safe in Harsh Conditions

- How do gumboots contribute to health benefits? Essential Protection Against Infections & Injuries