Contrary to a common assumption, not all tactical boots have steel toes. While some are equipped with safety toes for hazard protection, the core design of a tactical boot prioritizes mobility, support, and lightweight performance over the heavy-duty impact resistance that defines a traditional work boot.

The essential takeaway is that tactical boots are engineered for agility and operational readiness. Toe protection is a feature that can be added, but the absence of a steel toe is often a deliberate design choice to maximize flexibility and reduce operator fatigue.

What Defines a Tactical Boot?

To understand why a steel toe isn't a default feature, we must first understand the primary mission of a tactical boot. They are designed for personnel in demanding fields like law enforcement and the military.

The Core Mission: Performance and Mobility

A tactical boot's main purpose is to provide the support and durability of a traditional boot with the feel and agility of an athletic shoe.

The design is optimized for users who need to move quickly, quietly, and comfortably for long periods over varied and unpredictable terrain.

Lightweight and Flexible Construction

Unlike heavy work boots, tactical boots often use materials like nylon, synthetic leather, and durable fabrics. This construction drastically reduces weight, which helps minimize fatigue.

Thinner materials also allow for a much wider and more natural range of motion, which is critical for running, climbing, or kneeling.

All-Day Comfort and Breathability

Long hours on your feet demand superior comfort. Tactical boots typically feature soft, cushioned midsoles for excellent shock absorption.

They also incorporate moisture-wicking linings and breathable mesh panels to keep feet cool and dry, preventing blisters and discomfort during strenuous activity.

Superior Support and Traction

While lightweight, these boots do not compromise on stability. They feature reinforced ankle support to prevent injury on uneven ground.

The outsoles are engineered with aggressive tread patterns to provide exceptional grip on surfaces ranging from slick urban pavement to loose dirt and rock.

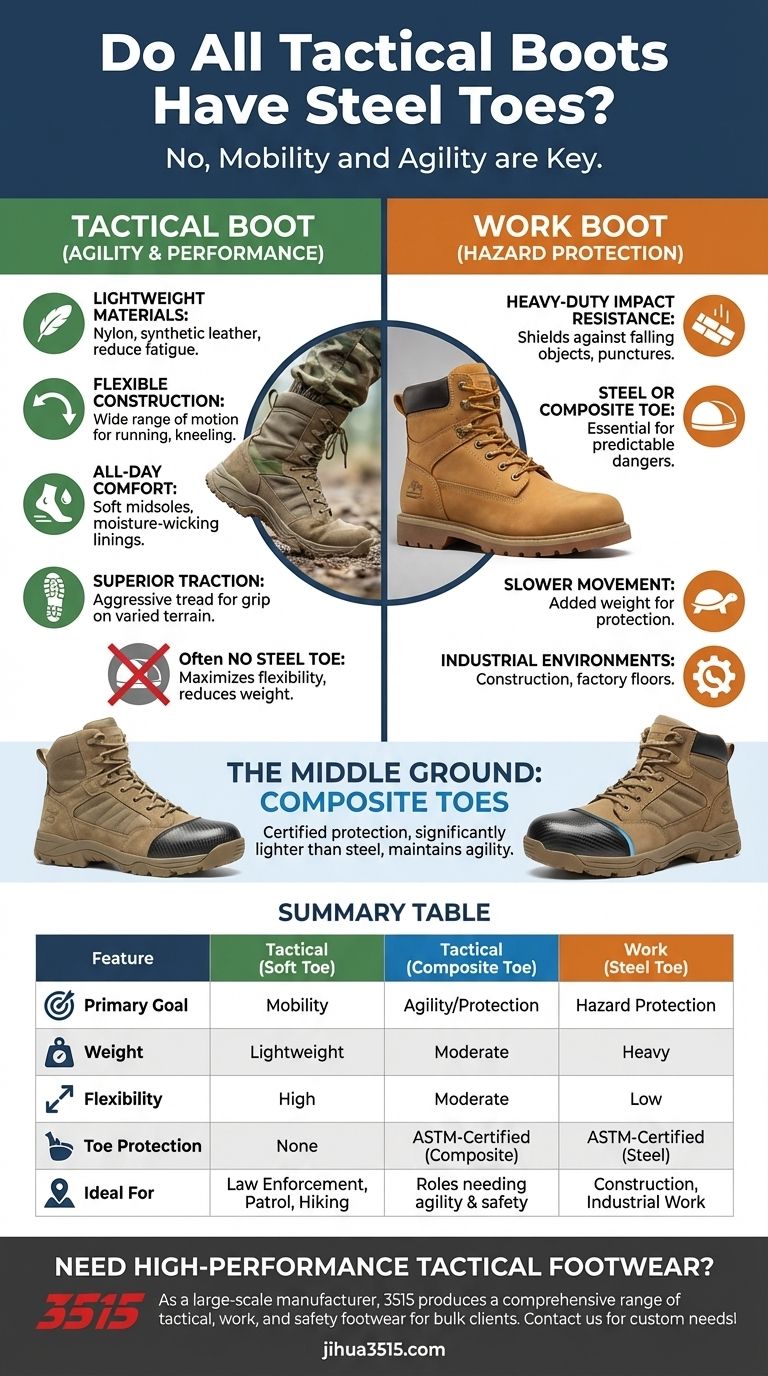

Tactical Boots vs. Work Boots: A Key Distinction

The confusion about steel toes often comes from blurring the line between tactical boots and traditional work or safety boots. Their design philosophies are fundamentally different.

Focus on Agility (Tactical)

The primary goal of a tactical boot is operational performance. Every feature is geared toward enabling the wearer to move effectively. Sacrificing weight and flexibility for a heavy steel toe would compromise this core mission.

Focus on Hazard Protection (Work)

The primary goal of a safety work boot is hazard mitigation. It is built to shield the foot from specific, predictable dangers like falling objects, punctures, or electrical currents. The steel or composite toe is central to this purpose, even if it adds weight.

The Rise of Composite Toes

For roles that require both mobility and impact protection, many modern tactical boots use composite safety toes. Made from materials like carbon fiber or Kevlar, these toes offer certified protection while being significantly lighter than steel.

This provides a middle ground, adding safety without the full weight and thermal conductivity penalty of a steel toe cap.

How to Choose the Right Boot for Your Needs

Selecting the correct footwear depends entirely on a clear understanding of your primary activities and environment.

- If your primary focus is rapid movement and all-day comfort (e.g., first responder, patrol, or demanding outdoor recreation): A lightweight tactical boot with a "soft toe" or non-safety toe is your ideal choice.

- If your primary focus is maximum protection in a hazardous industrial environment (e.g., construction or a factory floor): You require a boot with an ASTM-certified steel or composite safety toe, which may or may not be a tactical model.

- If you need a blend of agility and certified impact protection: Seek out a tactical boot specifically advertised with a composite safety toe to get the best of both worlds.

Ultimately, choosing the right boot means matching its specific design features to the demands of your mission.

Summary Table:

| Feature | Tactical Boot (Soft Toe) | Tactical Boot (Composite Toe) | Work Boot (Steel Toe) |

|---|---|---|---|

| Primary Goal | Mobility & Performance | Agility & Light Protection | Maximum Hazard Protection |

| Weight | Lightweight | Moderate | Heavy |

| Flexibility | High | Moderate | Low |

| Toe Protection | None | ASTM-Certified (Composite) | ASTM-Certified (Steel) |

| Ideal For | Law Enforcement, Patrol, Hiking | Roles needing agility & safety | Construction, Industrial Work |

Need High-Performance Tactical Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of tactical, work, and safety footwear for distributors, brand owners, and bulk clients. Whether you need lightweight soft-toe boots for maximum agility or composite-toe models for certified protection, we have the production capabilities and expertise to meet your exact requirements.

Contact 3515 today to discuss your custom footwear needs and get a quote!

Visual Guide

Related Products

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

People Also Ask

- What are the different types of tactical boots available? Find the Right Boot for Your Mission

- What special features can enhance the performance of tactical boots? Key Features for Superior Support & Protection

- What are the practical advantages of a rotary energy harvesting system in footwear? Power Your Tactical Edge

- Why should firefighters be involved in boot selection? Boost Safety & Performance with User Feedback

- What features provide ankle support and stability in tactical boots? The Complete System Explained

- What are some common types of tactical boots based on climate? Find the Perfect Boot for Your Environment

- How does the structure of high-top basketball shoes and tactical boots contribute to user safety? Expert Design Insights

- What should be included in a firefighting boot selection process? A Step-by-Step Guide for Departments