Yes, you can absolutely slip while wearing slip-resistant shoes. No shoe is "slip-proof." These shoes are engineered to significantly reduce the risk of slips and falls in hazardous conditions, but they cannot eliminate the possibility entirely. Their effectiveness is a function of their design, the surface you're on, and the type of spill.

The term "slip-resistant" describes a risk reduction, not a risk elimination. The shoe's effectiveness hinges on its ability to channel liquids away from the sole, but factors like worn-out treads, the type of contaminant, and the condition of the floor can still lead to a fall.

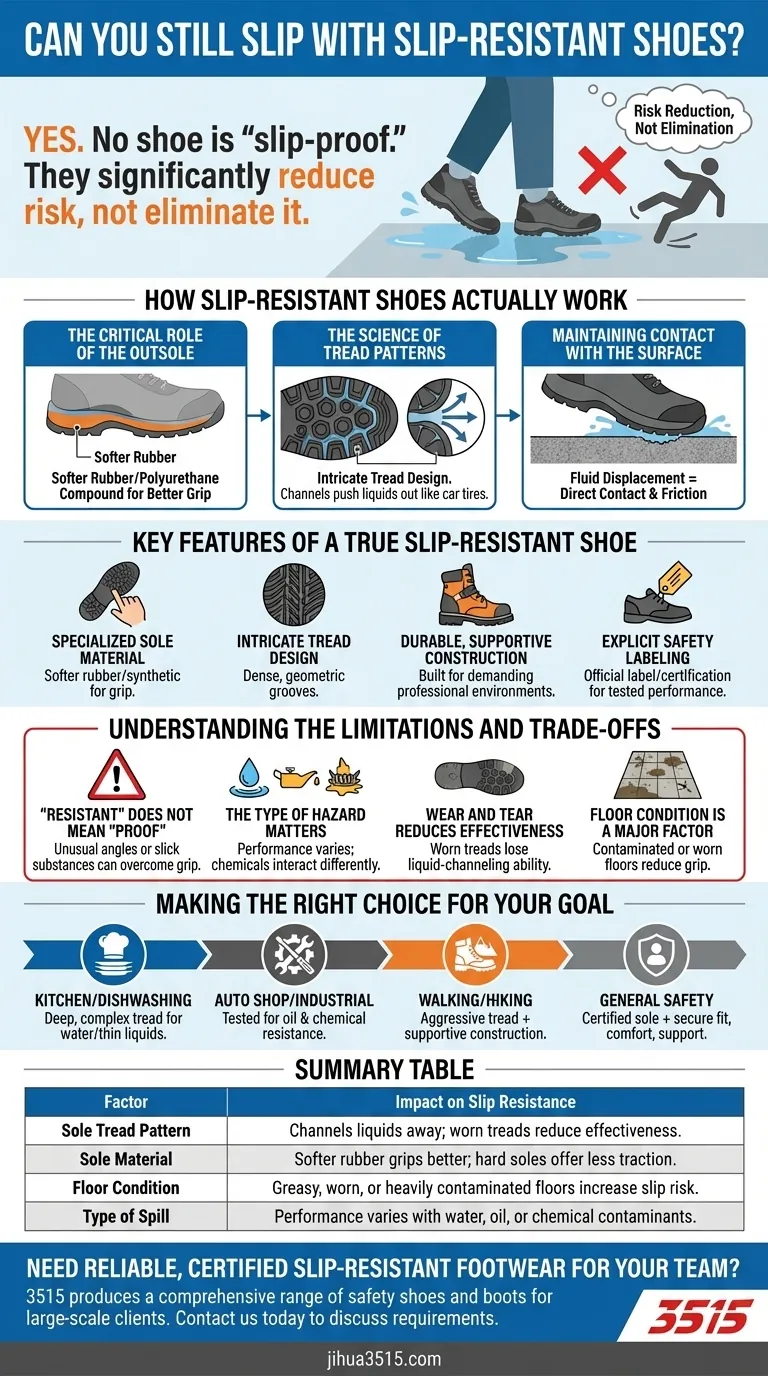

How Slip-Resistant Shoes Actually Work

To understand their limitations, you must first understand their core design principles. The magic is not in one feature, but in a system working together to maintain traction.

The Critical Role of the Outsole

The foundation of a slip-resistant shoe is its outsole, which is typically made from a softer rubber or polyurethane compound. These materials provide a naturally better grip on smooth surfaces compared to the harder plastics found on standard footwear.

The Science of Tread Patterns

The most crucial feature is the intricate tread pattern. These designs, often featuring hexagonal or circular shapes, are not for decoration. They create channels that actively push liquids out from under the shoe.

This functions much like the treads on a car tire, which prevent hydroplaning by dispersing water so the rubber can stay in contact with the road.

Maintaining Contact with the Surface

By effectively displacing fluids like water or oil, the sole of the shoe can make more direct, solid contact with the floor itself. This direct contact is what creates the friction necessary to prevent a slip.

Key Features of a True Slip-Resistant Shoe

When evaluating footwear, look for these specific, functional characteristics rather than just a marketing claim.

Specialized Sole Material

As mentioned, a softer rubber or synthetic sole is a primary indicator. This material is designed to grip, not just protect your foot.

Intricate Tread Design

Look for a dense pattern of small, geometric grooves. A flat or purely cosmetic tread will not provide meaningful slip resistance in wet conditions.

Durable, Supportive Construction

True slip-resistant footwear is often built for demanding professional environments. This means they typically feature reinforced materials and a sturdier build to provide stability and withstand heavy use.

Explicit Safety Labeling

The most reliable sign is an official label or certification. This indicates the shoe has been tested against a specific standard for slip resistance, providing a baseline of proven performance.

Understanding the Limitations and Trade-offs

Trusting your footwear blindly is a mistake. Knowing where these shoes fall short is essential for staying safe.

"Resistant" Does Not Mean "Proof"

This is the central point. The technology dramatically improves your odds, but an unusual angle, a sudden movement, or a particularly slick substance can still overcome the shoe's grip.

The Type of Hazard Matters

A shoe that performs exceptionally well on a water-covered tile floor might not be as effective on a surface with grease or industrial oils. The chemical properties of the spill can interact differently with the sole material.

Wear and Tear Reduces Effectiveness

Slip resistance is not permanent. As the soft rubber sole and its tread pattern wear down over time, the shoe's ability to channel liquids and grip the floor diminishes significantly.

Floor Condition is a Major Factor

Even the best shoes can be defeated by the environment. A heavily contaminated floor with thick grease or an old, worn-out surface with no natural texture provides very little for the shoe to grip onto.

Making the Right Choice for Your Goal

Select footwear based on your specific environment and the hazards you face most often.

- If your primary focus is a kitchen or dishwashing area: Prioritize shoes with deep, complex tread patterns designed specifically to channel away water and other thin liquids.

- If your primary focus is an auto shop or industrial setting: Look for shoes with labels explicitly stating they are tested for oil and chemical resistance, as the sole compound is critical.

- If your primary focus is stability for walking or hiking: Seek a combination of an aggressive, deep-lugged tread for loose surfaces and a supportive overall shoe construction.

- If your primary focus is general safety or fall prevention: Choose a shoe with a certified slip-resistant sole that also offers a secure fit, comfort, and good support.

Ultimately, viewing slip-resistant shoes as a critical piece of safety equipment—not a guarantee—is the correct approach to preventing falls.

Summary Table:

| Factor | Impact on Slip Resistance |

|---|---|

| Sole Tread Pattern | Channels liquids away; worn treads reduce effectiveness. |

| Sole Material | Softer rubber grips better; hard soles offer less traction. |

| Floor Condition | Greasy, worn, or heavily contaminated floors increase slip risk. |

| Type of Spill | Performance varies with water, oil, or chemical contaminants. |

Need reliable, certified slip-resistant footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of occupational footwear, engineered with advanced sole compounds and tread patterns tested for various hazardous conditions.

We can provide durable, supportive footwear tailored to your specific industry needs—whether for kitchens, factories, or outdoor work. Contact us today to discuss your requirements and enhance your workplace safety protocol with footwear you can trust.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- How should employers choose slip-resistant footwear? A Guide to Risk-Based Selection for Workplace Safety

- How can scuffing the outsoles of shoes improve traction? Prevent slips with simple physics.

- How can you identify slip-resistant shoes? Look for ASTM Certification & Key Features

- What are the six common types of non-slip shoes? Find the Perfect Grip for Your Work Environment

- What are the components of an ideal non-slip work shoe? Engineered for Ultimate Safety & Comfort

- What industries require special slip-resistant footwear? Protect Your Workforce from Slips and Falls

- What did the Scandinavian Journal of Work, Environment, and Health study find about slip-resistant footwear?

- What should be considered when choosing non-slip shoes for the workplace? Select the Right Safety Footwear