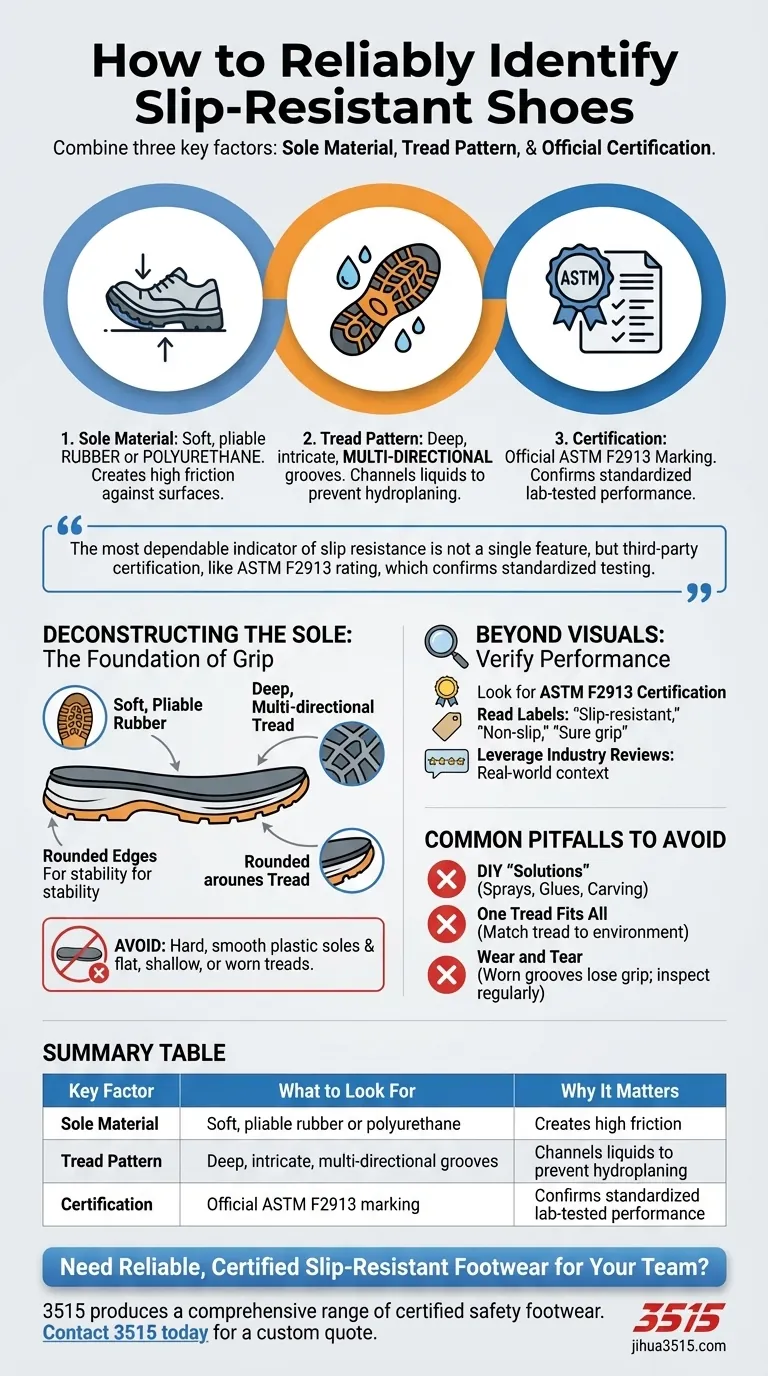

To reliably identify slip-resistant shoes, you must look for a combination of three key factors: soles made from high-traction materials like soft rubber, a deep and intricate tread pattern designed to channel liquids, and an official safety compliance marking, such as ASTM F2913. While marketing terms are helpful, these physical and certified attributes provide the true measure of a shoe's ability to prevent falls.

The most dependable indicator of slip resistance is not a single feature, but third-party certification. A shoe's design—from its sole material to its tread pattern—is important, but an official ASTM rating confirms it has passed standardized tests for grip on hazardous surfaces.

Deconstructing the Sole: The Foundation of Grip

A shoe's ability to resist slips is determined almost entirely by the design and material of its outsole. Understanding these components allows you to make a quick and accurate initial assessment.

The Material That Matters

The outsole material is your first clue. Look for soft, pliable rubber or polyurethane, as these materials have a naturally high coefficient of friction, meaning they create more grip against a surface.

Avoid shoes with hard, smooth plastic soles, which offer very little traction, especially on wet or greasy floors.

Engineering for Traction: The Tread Pattern

The pattern of grooves on the bottom of the shoe is critical. It's designed to channel water, oil, and other liquids away from the point of contact between the sole and the floor.

Look for deep, intricate, and multi-directional tread patterns. Small shapes like circles, hexagons, or squiggly lines create multiple edges to bite into the surface and prevent hydroplaning.

Flat, shallow, or worn-down treads are a significant red flag, as they cannot effectively disperse liquids.

The Role of Sole Shape

The overall shape of the sole also contributes to stability. Many high-quality slip-resistant shoes feature slightly rounded edges rather than sharp, flat ones. This design helps maintain contact with the floor even when your foot rolls slightly.

Beyond Visuals: How to Verify Performance

While a visual inspection is a good start, it isn't foolproof. True verification comes from standardized testing and explicit labeling.

The Gold Standard: ASTM Certification

The most reliable way to confirm slip resistance is to look for an ASTM (American Society for Testing and Materials) compliance marking. The key standard for footwear is ASTM F2913.

This marking certifies that the shoe has passed rigorous, standardized lab tests on various surfaces, often proving a coefficient of friction of .40 or higher. This is an objective, data-backed guarantee of performance.

Reading the Labels and Descriptions

Manufacturers of genuine slip-resistant shoes will state it clearly. When shopping, look for explicit terms like "slip-resistant," "non-slip," or "sure grip" in the product title, features, or description.

If this language is absent, you should assume the shoe does not offer enhanced traction.

Leveraging Industry Reviews

Check reviews from people who work in your specific industry. A chef's review of a shoe's performance on a greasy kitchen floor is far more valuable than a general comment on comfort. This provides real-world context that lab tests cannot.

Common Pitfalls to Avoid

Choosing the right shoe also means understanding what doesn't work and recognizing that "slip-resistant" can have its limits.

DIY "Solutions" Are Unreliable

Do not rely on aftermarket sprays, glues, or physical alterations like carving grooves into a sole. These are temporary, unreliable fixes that cannot match the safety and durability of professionally engineered footwear. They often provide a false sense of security.

One Tread Does Not Fit All

A shoe designed for wet tile in a hospital may not perform as well on the greasy floors of a commercial kitchen. The effectiveness of a tread pattern is tied to the specific type of hazard you face. Always consider your primary work environment.

Wear and Tear Degrades Grip

A slip-resistant shoe is only effective as long as its tread is intact. Once the grooves wear down and the sole becomes smooth, the shoe loses its ability to channel liquids and must be replaced. Regularly inspect your shoes for wear.

Making the Right Choice for Your Goal

Selecting the correct shoe requires matching its features to your specific safety needs and environment.

- If your primary focus is maximum verified safety (e.g., food service, healthcare): Prioritize shoes with a clear ASTM F2913 certification listed in the product specifications.

- If your primary focus is all-weather traction for general use: Focus on shoes made with soft rubber soles and deep, multi-directional tread patterns that have strong positive user reviews.

- If you are assessing a shoe with no information: Visually confirm it has a soft, pliable rubber sole with an intricate, channel-like pattern and avoid any shoe with a hard, flat, or smooth bottom.

Ultimately, investing in footwear with proven, certified slip resistance is a critical step in ensuring your personal safety at work and beyond.

Summary Table:

| Key Factor | What to Look For | Why It Matters |

|---|---|---|

| Sole Material | Soft, pliable rubber or polyurethane | Creates high friction against surfaces |

| Tread Pattern | Deep, intricate, multi-directional grooves | Channels liquids away to prevent hydroplaning |

| Certification | Official ASTM F2913 marking | Confirms standardized lab-tested performance |

Need Reliable, Certified Slip-Resistant Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with high-traction materials and ASTM-compliant designs to protect your workforce.

Contact 3515 today to discuss your safety footwear needs and receive a custom quote.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now