No, steel toe and composite toe are not the only options for safety shoes. While they are the most common, a third major category exists: alloy toe. Understanding the distinct properties of all three materials, as well as the different styles of safety footwear, is crucial for selecting the right protection for your specific work environment.

The most effective safety shoe is not simply the one with the strongest toe cap. It is the one whose materials, style, and protective features are correctly matched to the unique hazards and daily demands of your job.

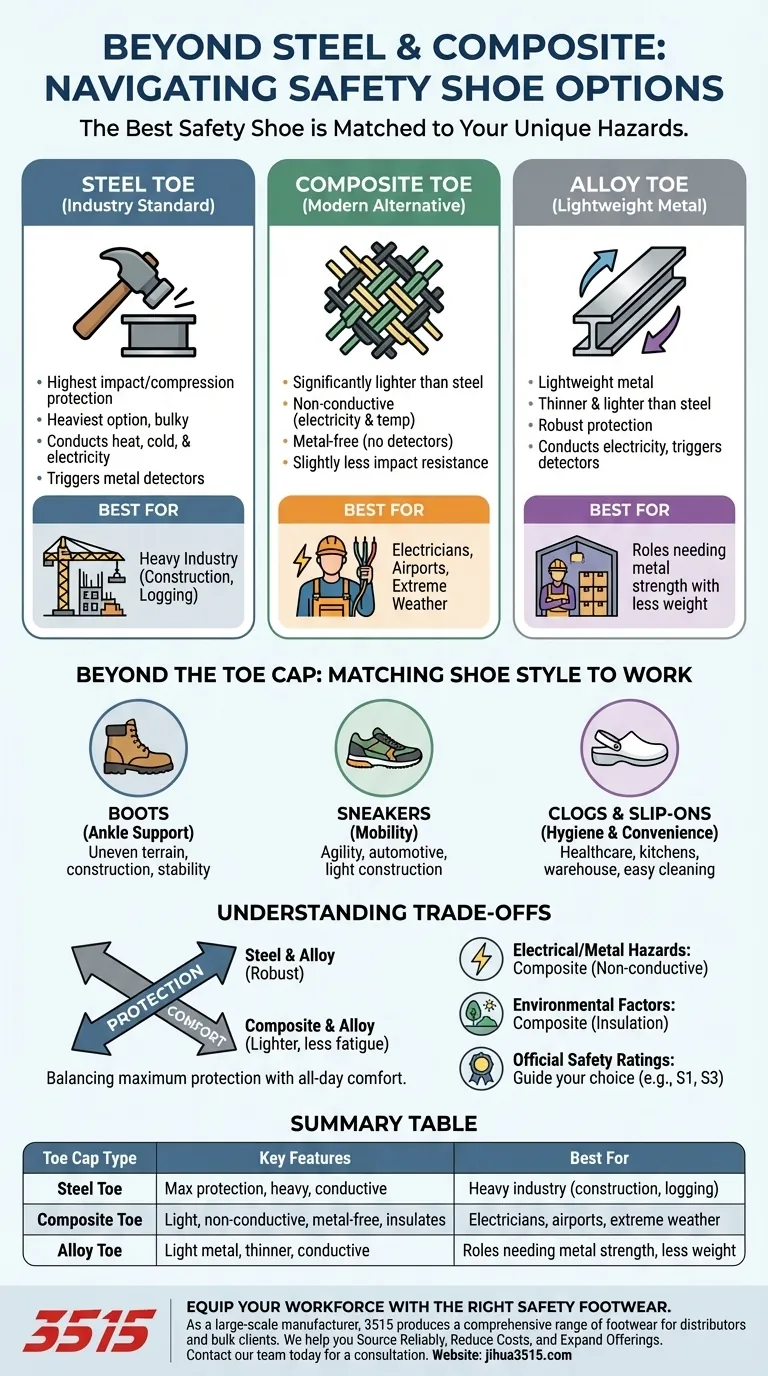

The Three Core Types of Safety Toes

The protective toe cap is the defining feature of a safety shoe. The material used dictates its weight, conductivity, and protective capabilities.

The Industry Standard: Steel Toe

Steel toes offer the highest level of protection against impact and compression. This makes them the traditional choice for high-risk industries.

However, they are the heaviest option, can be bulky, and will conduct heat, cold, and electricity. They also trigger metal detectors.

The Modern Alternative: Composite Toe

Composite toes are crafted from non-metallic materials like kevlar, carbon fiber, or plastic. This makes them significantly lighter than steel.

They do not conduct electricity or temperature, making them ideal for electricians or those working in extreme weather. They also won't set off metal detectors, a key benefit for airport and security personnel. Their primary drawback is that they offer slightly less impact resistance than steel.

The Lightweight Metal: Alloy Toe

Alloy toes are made from lightweight metals like aluminum or titanium. They provide a protective middle ground.

These caps are thinner and lighter than steel while still offering robust protection. Like steel, however, they conduct electricity and will set off metal detectors.

Beyond the Toe Cap: Matching Shoe Style to Your Work

The overall design of the shoe is just as important as the toe material. Different styles are engineered for different tasks and environments.

Boots for Ankle Support

Traditional work boots are essential for roles in construction or manufacturing where uneven terrain and falling objects pose a constant risk. They provide critical ankle support and stability.

Sneakers for Mobility

For automotive technicians or light construction workers, safety sneakers offer protection in a more flexible and mobile package. They allow for greater agility and comfort when squatting or moving frequently.

Clogs and Slip-ons for Hygiene and Convenience

In healthcare or kitchen environments, non-slip clogs are standard for their comfort and ease of cleaning. For warehouse workers, slip-on styles provide convenience for quickly gearing up.

Understanding the Trade-offs

Choosing the right safety shoe requires balancing competing factors. There is no single "best" option, only the best option for your specific needs.

Protection vs. Comfort

The core trade-off is often between maximum protection and all-day comfort. Steel offers the most robust safety but is heavy, while composite and alloy toes reduce weight and fatigue during long shifts.

Electrical and Metal Hazards

If you are an electrician or work in a secure facility with metal detectors, the choice is clear. Composite toes are non-negotiable as they are non-conductive and metal-free.

Environmental Factors

Composite materials provide superior insulation against extreme heat or cold, making them far more comfortable in challenging climates. Steel and alloy will readily transfer temperature to your feet.

Official Safety Ratings

Ultimately, your choice should be guided by formal protection classes (e.g., S1, S1P, S3). These standardized ratings define the specific hazards a shoe is built to withstand, from puncture resistance to water protection.

Making the Right Choice for Your Role

Select your footwear by starting with the non-negotiable requirements of your job, then consider your comfort preferences.

- If your primary focus is maximum impact protection in heavy industry like construction or logging, the superior strength of a steel toe is your most reliable choice.

- If your primary focus is all-day comfort, electrical safety, or passing through metal detectors, the lightweight, non-conductive properties of a composite toe are ideal.

- If your primary focus is reducing weight without sacrificing the strength of metal, an alloy toe offers an excellent balance, provided conductivity is not a concern.

The right safety shoe empowers you to work confidently and comfortably by aligning its specific features with the real-world demands of your job.

Summary Table:

| Toe Cap Type | Key Features | Best For |

|---|---|---|

| Steel Toe | Maximum impact/compression protection, heaviest, conducts temperature/electricity | Heavy industry (construction, logging) |

| Composite Toe | Lightweight, non-conductive, does not set off metal detectors, good insulation | Electricians, airports, extreme weather |

| Alloy Toe | Lightweight metal, thinner profile, conducts temperature/electricity | Roles needing metal strength with less weight |

Equip Your Workforce with the Right Safety Footwear

Choosing the correct safety shoe is critical for productivity and protection. As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the perfect match for your specific job hazards and comfort needs.

We help you:

- Source Reliably: Get consistent quality and volume from a trusted manufacturer.

- Reduce Costs: Benefit from competitive pricing on bulk orders.

- Expand Your Offerings: Access a full catalog of safety footwear styles.

Let's discuss your specific requirements. Contact our team today for a consultation and see how we can support your business.

Visual Guide

Related Products

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Why must enterprises maintain a stable supply of personal protective equipment like Safety Shoes? Ensure Worker Safety

- When should safety shoes be worn? Protect Your Workforce from Common Hazards

- How do specialized safety shoes contribute to the reduction of industrial accidents? Enhance Your Workplace Safety

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What are the essential comfort and durability features of security guard safety boots? Ensure All-Day Protection & Performance

- What are the production benefits of choosing modular electronic components for smart protective footwear? Scale Faster

- How does the structural design of industrial safety shoes prevent Tarsal Tunnel Syndrome? Protect Worker Foot Health

- What is the function of electrical insulation materials in the design of safety footwear? Vital High-Voltage Protection