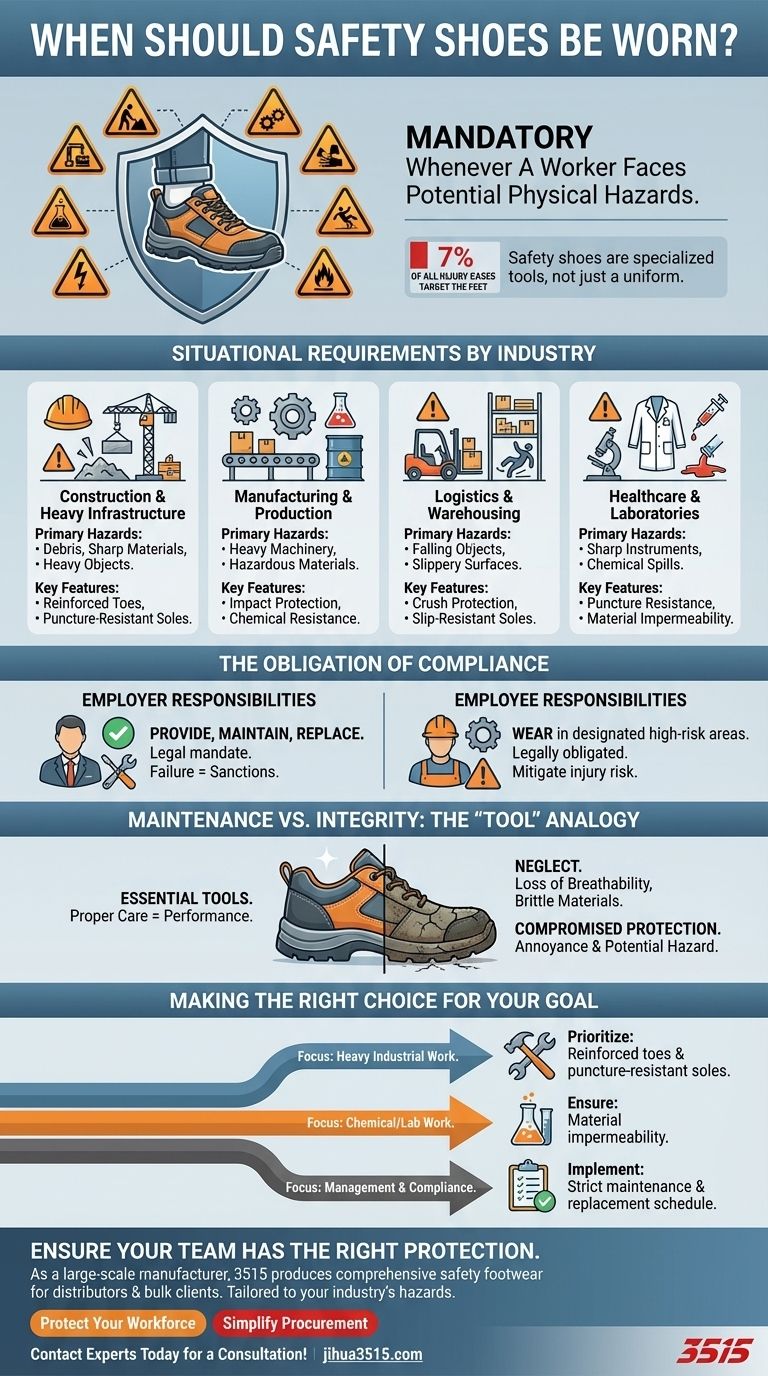

Safety shoes must be worn whenever a worker faces potential physical hazards, specifically during tasks involving heavy material handling, machinery operation, or exposure to dangerous chemicals. If your environment presents risks of crushing injuries, punctures from sharp objects, electrical shock, or chemical burns, protective footwear is a mandatory piece of personal protective equipment (PPE).

Workplace accidents frequently target the feet, accounting for roughly 7% of all injury cases. Safety shoes are not merely a uniform requirement; they are specialized tools that must be matched to the specific risks of your environment and maintained with the same rigor as heavy machinery.

Situational Requirements by Industry

Construction and Heavy Infrastructure

In these environments, the primary threats are debris, sharp materials, and heavy objects. Safety shoes are non-negotiable here to prevent puncture wounds from nails or crushing injuries from dropped equipment.

Manufacturing and Production

Workers operating heavy machinery or handling hazardous materials face significant risks. Footwear here serves a dual purpose: physical protection against impact and barrier protection against chemical exposure.

Logistics and Warehousing

The risks in logistics are often underestimated but critical. Personnel must wear safety shoes to protect against falling objects from shelving and to maintain traction on potentially slippery surfaces.

Healthcare and Laboratories

Safety footwear extends beyond industrial sites. In these sectors, shoes must protect against sharp instruments and unexpected chemical spills, preventing biological or chemical contamination.

The Obligation of Compliance

Employer Responsibilities

Safety is a legal mandate, not a suggestion. Employers are required to provide, maintain, and replace safety shoes for their workforce. Failure to provide suitable footwear can result in labor inspection sanctions.

Employee Responsibilities

Employees are legally obligated to wear the provided gear in designated high-risk areas. It is the worker's duty to utilize the equipment effectively to mitigate the 7% injury statistic associated with foot trauma.

Understanding the Trade-offs: Maintenance vs. Integrity

The "Tool" Analogy

You must view your safety shoes exactly as a forestry worker views their saw or a tiler views their trowel. They are essential tools, not just clothing.

The Cost of Neglect

There is a direct trade-off between maintenance and performance. Without proper care, safety shoes lose breathability and the materials can become brittle.

Compromised Protection

A neglected shoe is a dangerous shoe. Dirt and wear can destroy the protective features designed to save your foot. Instead of a safety device, a degraded shoe becomes an annoyance and a potential hazard itself.

Making the Right Choice for Your Goal

Selecting the correct footwear depends entirely on the specific "features required by the job."

- If your primary focus is heavy industrial work: Prioritize shoes with reinforced toes and puncture-resistant soles to counter crushing and sharp debris.

- If your primary focus is chemical or laboratory work: Ensure your footwear selection focuses on material impermeability to prevent skin exposure to hazardous substances.

- If your primary focus is management and compliance: Implement a strict maintenance and replacement schedule to avoid liability and ensure protective features remain functional.

Treat your footwear with the same respect as dangerous machinery, because it is the only barrier between you and a life-altering injury.

Summary Table:

| Industry / Setting | Primary Hazards | Key Shoe Features Required |

|---|---|---|

| Construction & Heavy Infrastructure | Debris, sharp materials, heavy objects | Reinforced toes, puncture-resistant soles |

| Manufacturing & Production | Heavy machinery, hazardous materials | Impact protection, chemical resistance |

| Logistics & Warehousing | Falling objects, slippery surfaces | Crush protection, slip-resistant soles |

| Healthcare & Laboratories | Sharp instruments, chemical spills | Puncture resistance, material impermeability |

Ensure your team has the right protection. As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes and boots tailored to your industry's specific hazards. Protect your workforce and simplify your procurement — contact our experts today for a consultation!

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How is the absence of PPE (safety shoes & helmets) categorized in construction motion data labeling? Unlock Real-Time Safety Insights!

- Why is Precise Sizing of Safety Shoes Critical in Preventing Ulcers? Expert Guide on Proper Fit

- What primary protective functions do professional safety shoes provide? Essential Industrial Safety Guide

- What are the advantages of KPU moulding material for labour protection shoes? Superior Durability & Comfort

- Why are Force Sensing Resistor (FSR) sensors core for Safety Shoes? Ensure Workplace Compliance with Smart Tech

- Why is an advanced AR engine essential for safety shoes? Enhance Product Visualization and Spatial Accuracy

- Where can one purchase firefighter boots? Find Trusted Sources for NFPA-Certified Gear

- What are the benefits of the insulating components in women's safety toe work boots? Achieve Comfort and Safety in Extreme Cold