The Million-Dollar Mistake: When 'Top-Spec' Boots Backfire

The feedback from the field is in, and it’s not good. The state-of-the-art tactical boots you procured in bulk—the ones that ticked every box for durability and waterproofing—are causing widespread issues. Blisters are rampant on long marches in the heat. The soles, designed for maximum protection, are too stiff and heavy for agile maneuvers.

What looked like the perfect choice on a specification sheet is failing under the pressures of the real world. Now you're facing a cascade of problems: budget wasted on unusable gear, diminished team performance, and the logistical nightmare of returns and replacements. It’s a familiar story, and it's incredibly frustrating.

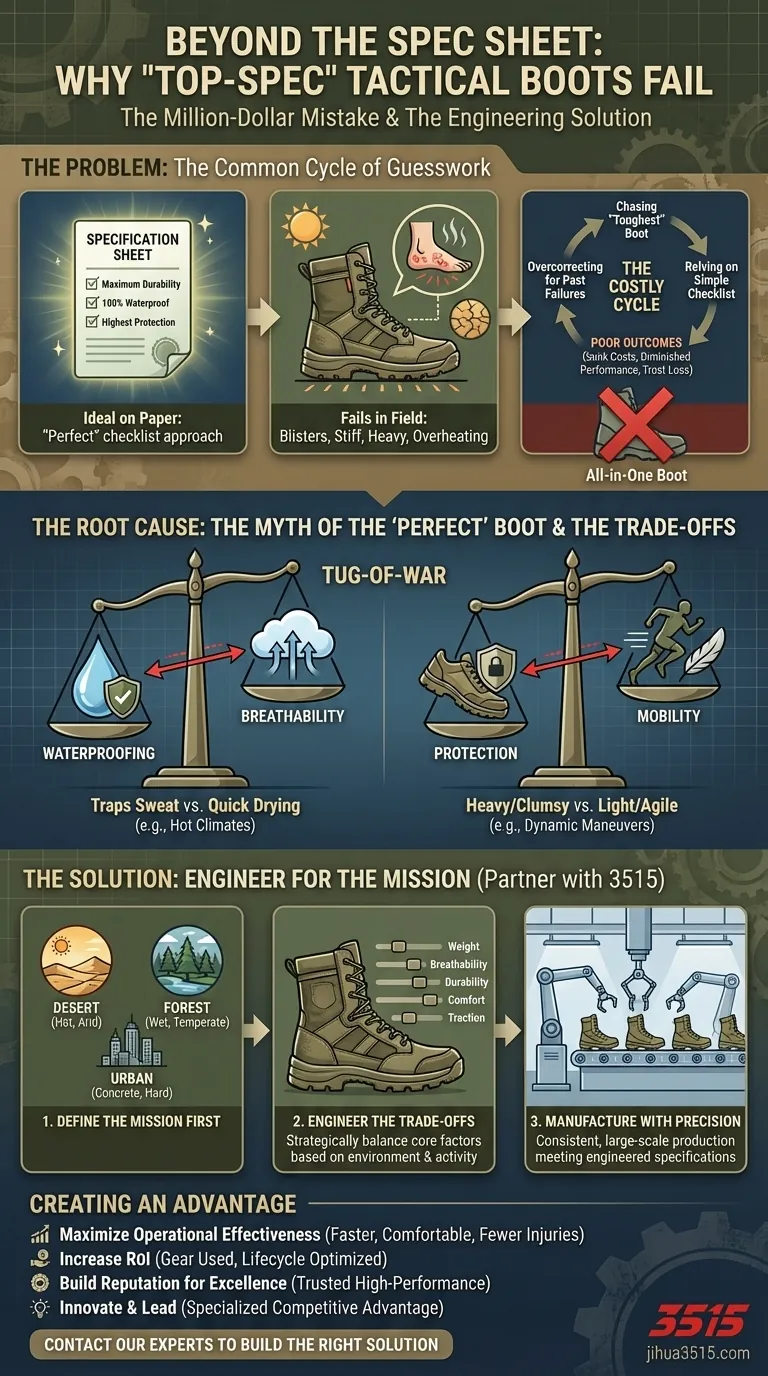

The Common—and Costly—Cycle of Guesswork

If this scenario sounds familiar, you're not alone. Many organizations, from government agencies to private brand owners, fall into the same trap. Faced with a complex procurement decision, they resort to a few common but flawed strategies:

- Chasing the "Toughest" Boot: They select the boot with the thickest leather and most aggressive sole, assuming durability is the ultimate virtue.

- Overcorrecting for Past Failures: If last year's boots leaked, this year's order is for a completely waterproof model, without considering if the operational environment has changed to a hot, dry climate.

- Relying on a Simple Checklist: They treat the five core factors—traction, durability, breathability, weight, and comfort—as independent features to be maximized, rather than an interconnected system.

This approach inevitably leads to poor outcomes. The business consequences are severe: sunk costs in equipment that hinders rather than helps, damage to your brand's reputation for quality, and a loss of trust from the end-users who rely on their gear to perform. You're left wondering: "We bought boots that met the specs. Why aren't they working?"

The Root Cause: The Myth of the 'Perfect' All-in-One Boot

The problem isn't that you chose a "bad" boot. The problem is that the concept of a single, perfect boot that excels in everything is a myth. The real root of the issue lies in a fundamental principle that spec sheets often ignore: every design choice is a trade-off.

The five critical factors of a boot are in a constant state of tug-of-war. Improving one almost always comes at the expense of another. The "common solutions" fail because they ignore this reality.

The Tug-of-War: Waterproofing vs. Breathability

A boot with a fully waterproof membrane is excellent at keeping water out during a river crossing. But that same membrane traps sweat vapor inside. During a long patrol in 40°C heat, the foot becomes soaked from the inside out, leading to the very blisters and discomfort you sought to avoid. A more breathable, non-waterproof boot would have gotten wet, but it also would have dried out far more quickly.

The Balancing Act: Protection vs. Mobility

A heavily armored boot with a rigid, puncture-proof sole offers incredible protection in a collapsed structure or on sharp rocks. But that same rigidity makes it heavy and clumsy when running, climbing, or trying to move quietly. The energy cost of lifting that extra weight with every step accumulates over miles, leading to premature fatigue. A lighter, more flexible boot sacrifices some protection for a massive gain in speed and efficiency.

Your procurement failed not because the boot's quality was poor, but because the specific balance of its trade-offs was wrong for the mission.

The Solution: Engineering for the Mission, Not the Checklist

To break this cycle, you don't need a better checklist; you need a better process and a partner who understands that a boot is an engineered system. The goal isn't to find a boot that's "the best," but to manufacture the boot that has the right balance of features for a specific set of conditions.

This is where a manufacturing partner like 3515 becomes essential. We aren't just order-takers; we are problem-solvers who build footwear based on a deep understanding of these performance trade-offs. Our approach is fundamentally different:

- Define the Mission First: We start with your end-user's primary environment. Is it a hot, arid desert? A wet, temperate forest? Urban concrete? This dictates the entire design philosophy.

- Engineer the Trade-offs: Based on the mission, we strategically balance the five core factors. For a rapid-deployment team in a hot climate, we prioritize low weight and maximum breathability, accepting a trade-off in long-term durability. For garrison duty, we prioritize all-day comfort and support on hard surfaces.

- Manufacture with Precision: Our large-scale production capabilities allow us to create footwear that consistently meets these precise, engineered specifications—ensuring every pair in a 10,000-unit order performs exactly as designed.

Our value isn't just in making boots; it's in leveraging our expertise to ensure you get the right boot, preventing the costly mistakes of a spec-sheet-only approach.

From Solving a Problem to Creating an Advantage

When you shift from buying off-the-shelf products to partnering on an engineered solution, everything changes. The recurring problem of failed gear disappears, and new possibilities open up.

With footwear correctly matched to the mission, you can:

- Maximize Operational Effectiveness: Your teams move faster, stay comfortable longer, and suffer fewer preventable injuries.

- Increase Your Return on Investment: You invest in gear that gets used, lasts for its intended lifecycle, and actively contributes to mission success.

- Build a Reputation for Excellence: As a distributor or brand owner, you become known for providing high-performance, reliable footwear that users trust.

- Innovate and Lead: You can develop specialized footwear for niche applications, creating a distinct competitive advantage in the market.

Choosing the right footwear is more than a logistical decision; it's a strategic investment in performance, safety, and your organization's reputation. Stop the cycle of trial-and-error procurement. Our team at 3515 doesn't just manufacture boots; we partner with you to engineer the precise solution your mission demands. Whether you're developing a new product line or equipping an entire force, we have the expertise and scale to deliver footwear that performs flawlessly from the factory to the field. Let's discuss the specific challenges your team faces and build the right solution together. Contact Our Experts

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

Related Articles

- Why Even the Best Tactical Boots Fail—And How to Choose the Right Ones

- The Versatility Trap: Why Your "Do-It-All" Tactical Boot Is Failing Your Customers

- Why Your Team Hates Their New Tactical Boots: A Buyer's Guide to What Really Matters

- Your Tactical Boots Are Failing. It’s Not Your Team's Fault.

- Why Most Tactical Boots Fail: It’s Not the Durability, It’s the System