You’ve done the research. You invested a significant portion of your budget into acquiring new, top-of-the-line tactical boots for your team. They have the best safety ratings, the most rugged materials, and a brand name everyone recognizes. Yet, a few weeks into deployment, the reports start trickling in: blisters, sore joints, complaints about weight, and even a few preventable slips.

The expensive gear meant to be an asset has become a liability. Morale dips, and performance is compromised—all because of footwear.

This isn't a fluke. It's a predictable outcome of a flawed, yet common, procurement strategy.

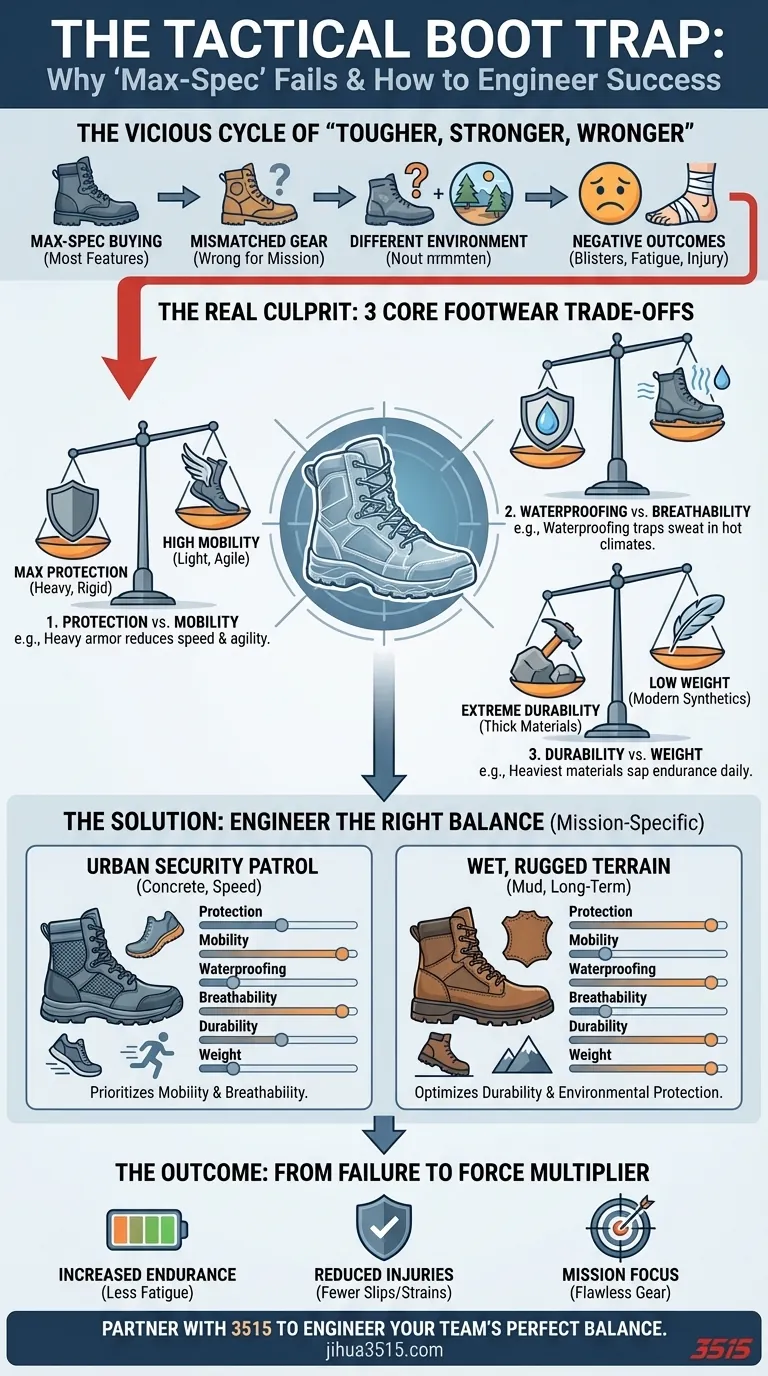

The Vicious Cycle of "Tougher, Stronger, Wronger"

When faced with outfitting a team for a high-stakes environment, many procurement managers and team leaders fall into the same traps. They believe the solution is to find the single "best" boot available. This often leads to:

- Buying the "Max-Spec" Boot: Choosing the boot with the most features—the thickest leather, the highest waterproof rating, a steel toe, and aggressive treads—assuming more is always better.

- Copying Another Organization: Selecting the same boots used by a military special forces unit, without considering that your team's operational environment (e.g., urban concrete vs. rural mountains) is completely different.

- Focusing Solely on Durability: Prioritizing boots that will last for years, without calculating the cost of that durability in terms of weight and the physical toll it takes on the wearer every single day.

The business consequences are significant and immediate. You face wasted capital on equipment your team can't or won't use effectively, reduced operational readiness as personnel struggle with fatigue and discomfort, and an increased risk of slips, trips, and falls that can lead to lost-time injuries. You aimed for an upgrade but ended up with a downgrade in performance.

The Real Culprit: The Three Trade-Offs Every Buyer Must Understand

The fundamental mistake is thinking of a tactical boot as a single product. It's not. A high-performance boot is a carefully engineered balance of competing properties.

The reason the "toughest" boot often fails is that it has been optimized for one variable at the expense of others that are equally critical for your specific mission. Every design decision involves a trade-off. Ignoring them is the root cause of nearly every footwear failure.

Here are the three non-negotiable laws of footwear design:

1. Protection vs. Mobility

A heavily armored boot with a rigid sole and safety toe offers maximum protection from impact and puncture. But that armor comes with weight and stiffness, reducing agility and increasing the energy needed for every step. Conversely, a lightweight, flexible boot enhances speed and conserves energy but offers far less protection.

- The Mistake: Giving a rapid-response urban team a heavy, rigid boot designed for navigating rubble. You've protected them from a threat they won't face at the cost of the mobility they desperately need.

2. Waterproofing vs. Breathability

A boot with a fully waterproof membrane is excellent at keeping water out. However, it is also excellent at keeping sweat in. In a hot and arid climate, that trapped moisture can lead to blisters and heat injuries faster than any rainstorm.

- The Mistake: Deploying a fully waterproof boot in a desert environment. Your team's feet will be soaked from the inside out, defeating the entire purpose of the feature.

3. Durability vs. Weight

The toughest, most abrasion-resistant materials like thick, full-grain leather are also the heaviest. Lighter synthetic materials can offer excellent performance and comfort but may have a shorter operational lifespan.

- The Mistake: Choosing the heaviest leather boot for a role that requires covering long distances daily. The boot might last five years, but the wearer's endurance will be sapped by the end of every shift.

Beyond Off-the-Shelf: Engineering the Right Balance

The solution, therefore, is not to find a mythical "one-size-fits-all" perfect boot. The solution is to define your operational context and then source a boot built with the precise balance of trade-offs that your mission demands.

This is where a manufacturing partner, not just a product vendor, becomes essential. As a large-scale producer of all types of footwear, 3515 is built on a deep understanding of these engineering principles. We don't just offer a catalog; we provide the capability to produce footwear that directly addresses the root cause of performance failure.

- For Urban Security Patrols: We can manufacture a lightweight boot using breathable synthetic uppers, a flexible midsole for comfort on concrete, and a slip-resistant outsole—prioritizing mobility and breathability.

- For Industrial Site Response Teams: We can build a boot compliant with ASTM F2413 standards, featuring a composite safety toe and puncture-resistant plate, but using modern materials to reduce weight—balancing certified protection with reduced fatigue.

- For Field Teams in Wet, Rugged Terrain: We can produce a durable, high-ankle boot with a waterproof membrane and an aggressive lug pattern—optimizing for durability and environmental protection.

Our value is not in a single product, but in our ability to deliver the right combination of materials and construction to solve your specific operational puzzle.

From Footwear Failure to Force Multiplier

When your team is equipped with footwear truly matched to their mission, the change is transformative. The persistent "gear problem" disappears and is replaced by tangible performance gains.

This isn't just about comfortable feet; it's about unlocking new potential. Teams can stay on-mission longer with less fatigue, improving their overall endurance and effectiveness. Injury rates from slips and strains decrease, protecting both your people and your budget. Most importantly, when gear works flawlessly, your team can focus 100% of their attention on the mission at hand. You haven't just bought boots; you've invested in a genuine force multiplier.

Your operational challenges are unique, and your equipment solution should be too. Stop searching for the perfect off-the-shelf boot and start a conversation about building the right one. Our team can help you analyze your specific needs and develop a footwear solution that delivers the precise balance of protection and performance your environment demands. Contact Our Experts to discuss your project requirements.

Visual Guide

Related Products

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

Related Articles

- Why Even the Best Tactical Boots Fail—And How to Choose the Right Ones

- Camouflage vs. Durability: The False Choice in Tactical Footwear

- The 'One-Boot-Fits-All' Fallacy: Why Your Tactical Footwear Isn't Selling—And How to Fix It

- Why Your Tactical Boots Are Failing: It’s Not the Pattern, It’s the Platform

- Your Tactical Boots Are Failing. It’s Not Your Team's Fault.