You’ve invested months developing a new line of tactical boots. The spec sheet is impressive: high-denier Cordura, aggressive Vibram soles, reinforced stitching. They look indestructible. But then, the first round of field reports lands on your desk, and the feedback is brutal.

Seams are blowing out on rocky terrain. The "waterproof" membrane is turning the boot into a swamp in humid climates, sidelining operators with severe blisters. The product that looked so strong in the lab is failing the very people who depend on it most. Why does this keep happening?

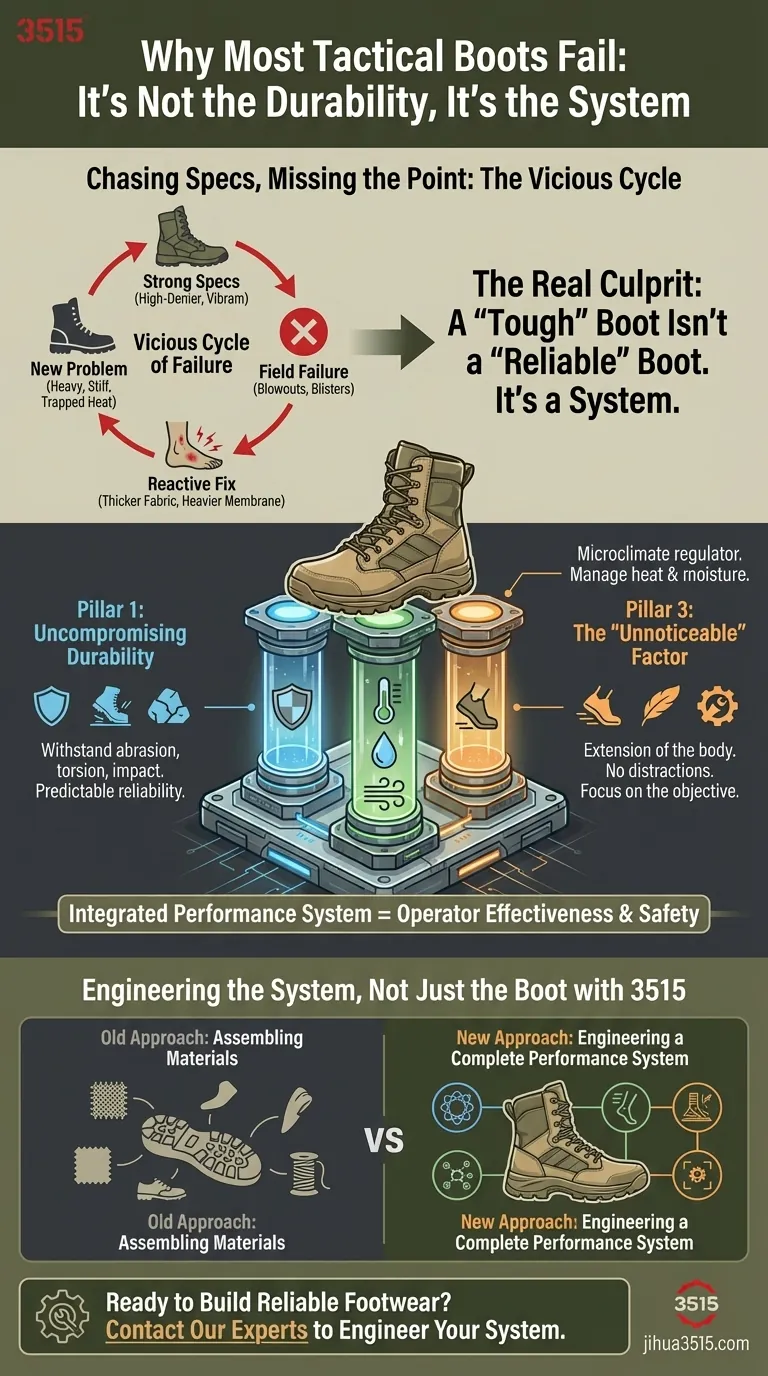

The Vicious Cycle: Chasing Specs, Missing the Point

When a product fails, the typical response is to double down on the perceived weakness.

- "The seams failed? Let's use a thicker, tougher fabric." The result is often a boot that's too heavy and stiff, restricting movement and causing fatigue. It also traps more heat, creating new problems.

- "Users complained about wet feet? Let's add a heavier waterproof membrane." This common "fix" often ignores sweat. It turns the boot into a plastic bag, trapping moisture from the inside. The outcome? Blisters, maceration, and a catastrophic drop in operator performance.

- "Let's just copy the design of a best-seller." This approach fails because it copies the what without understanding the why. A design optimized for a dry, desert environment will fail disastrously in a temperate jungle, but the spec sheet might look nearly identical.

This reactive approach creates a vicious cycle of solving one problem while creating another. The business consequences are severe: costly returns, damaged brand reputation, and lost contracts. More importantly, it erodes the trust between your brand and the end-user who faces real-world risks.

The Real Culprit: A 'Tough' Boot Isn't a 'Reliable' Boot

The fundamental mistake is treating boot design as a checklist of individual features. We fixate on "durability" or "waterproofing" as isolated metrics. But in the field, performance is not a feature; it's an integrated system. The true cause of failure isn't a single weak material, but an imbalanced system that compromises the operator.

A truly reliable tactical boot is built on three interconnected pillars. If one is weak, the entire structure collapses under pressure.

Pillar 1: Uncompromising Durability

This is the baseline. The materials and construction must withstand extreme abrasion, torsion, and impact without structural failure. This is about predictable reliability—the absolute confidence that the boot will not fall apart at a critical moment.

Pillar 2: Environmental Versatility

This is where most designs fail. The boot must act as a microclimate regulator for the foot. It needs to provide support and protection while actively managing heat and moisture from both the outside and the inside. A boot that can't breathe is as much a liability as one that leaks. This thermoregulation is critical for preventing the fatigue and injury that can compromise a mission.

Pillar 3: The "Unnoticeable" Factor

The ultimate goal of any piece of gear is to become an extension of the body, not a distraction. A superior boot doesn't chafe, create hot spots, or restrict natural movement. Its weight, fit, and flexibility work in harmony, allowing the operator to maintain 100% focus on their objective, not on the gear that's supposed to be helping them.

Focusing only on Pillar 1 (Durability) while ignoring Pillars 2 and 3 is the single greatest reason why technically "strong" boots fail in the real world.

Engineering the System, Not Just the Boot

To solve this problem permanently, you need to shift your approach from assembling materials to engineering a complete performance system. This requires a deep, practical understanding of how materials interact under stress, in varied climates, and on the human body.

This is where our expertise at 3515 becomes your strategic advantage. We don't just manufacture footwear; we engineer solutions based on a holistic understanding of these three pillars.

- For Durability: We don't just select "tough" fabrics. We select and test material combinations proven to withstand specific field conditions, from the abrasion of scree slopes to the constant flexing of a 20-mile march.

- For Versatility: Our expertise lies in creating laminate packages and construction methods that strike the critical balance between water resistance and breathability. We build boots that keep water out while actively expelling the sweat that causes debilitating blisters.

- For the "Unnoticeable" Factor: Our designs are built around the anatomy of the foot in motion. We obsess over details like lacing systems that prevent pressure points, ankle construction that provides support without restricting mobility, and material choices that minimize weight.

We understand the trade-offs. We know that the perfect boot for a desert law enforcement unit is fundamentally different from one designed for a mountain reconnaissance team. Our process is built to deliver the right system for the specific mission.

Beyond Reliability: Building a Reputation That Lasts

When you partner with a manufacturer who understands the entire performance system, the conversation changes. Instead of fixing field failures, you start building a reputation for unshakeable reliability.

Suddenly, you can confidently pursue more demanding contracts. Your product development cycle accelerates because you get it right the first time. Your brand becomes synonymous not with a single feature, but with the trust that your gear will perform when everything is on the line. This is the foundation of a lasting, respected brand in the tactical space.

Your next project deserves more than just a spec sheet. It requires an expert partner dedicated to engineering a system that guarantees operator effectiveness and safety. If you're ready to move beyond the cycle of field failures and build footwear that truly delivers on its promise, we should talk.

Contact Our Experts to discuss how we can engineer the right performance system for your specific needs.

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

Related Articles

- Camouflage vs. Durability: The False Choice in Tactical Footwear

- Your Tactical Boots Are Failing. It’s Not Your Team's Fault.

- Tactical vs. Combat Boots: How the Wrong Choice Is Costing Your Organization

- Beyond the Spec Sheet: The Real Reason Your Tactical Footwear Fails

- Why Your Team Hates Their New Tactical Boots: A Buyer's Guide to What Really Matters