For work boots, Goodyear welt construction is chosen for its superior durability, water resistance, and long-term value. This method, which involves stitching a strip of leather (the "welt") between the boot's upper and the outsole, creates an exceptionally robust and repairable piece of footwear ideal for demanding environments.

The core reason to choose a Goodyear welt is viewing your boots as a long-term investment. While the upfront cost is higher, the ability to repeatedly resole the boot and its inherent durability mean it will outlast multiple pairs of cheaper, disposable footwear.

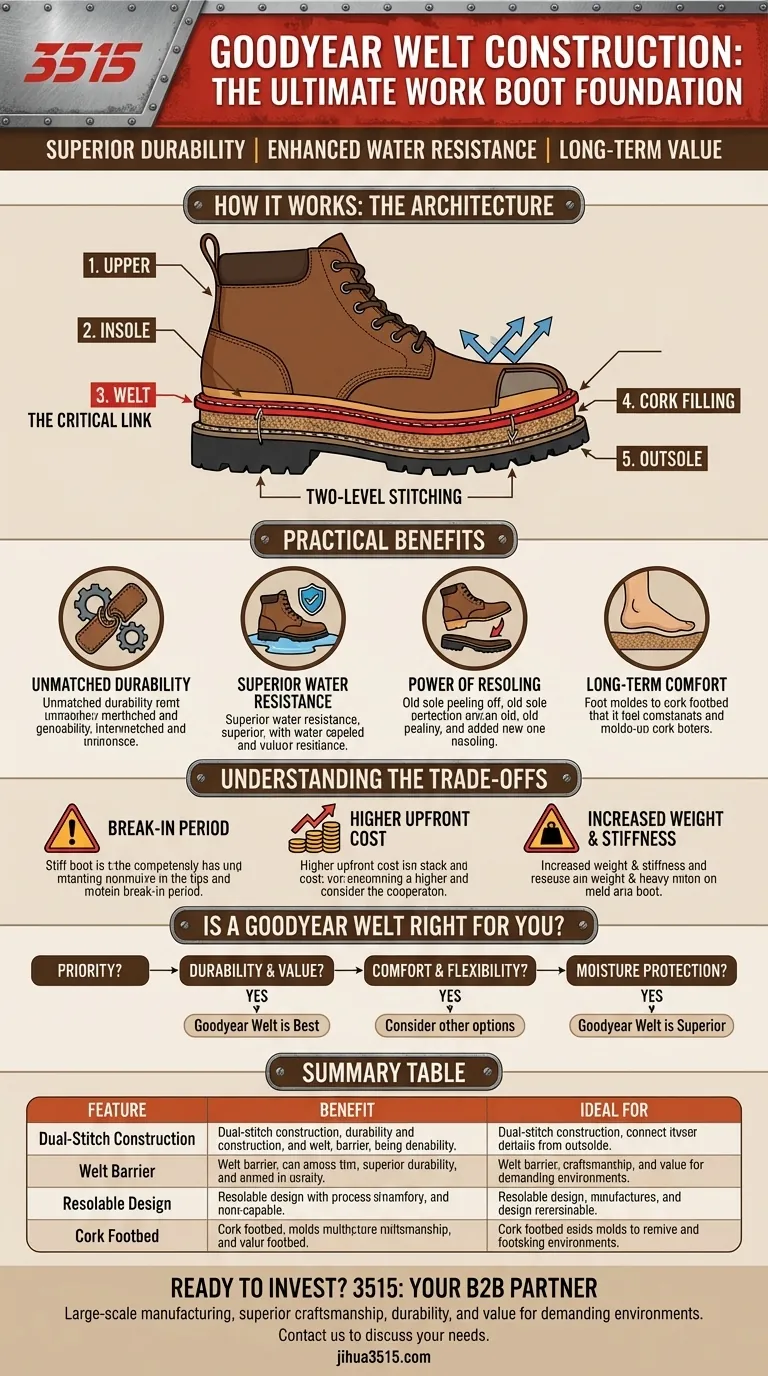

How a Goodyear Welt Actually Works

To understand the benefits, you must first understand the architecture. A Goodyear welt is a specific, multi-step construction method that creates a highly stable platform.

The Upper and the Insole

The process begins by attaching the boot's upper—the main leather body of the boot—to the insole, which is the layer your foot rests on. This creates the initial shape and structure.

The Role of the Welt

A strip of leather or synthetic material, known as the welt, is then stitched around the perimeter of the boot. This welt is the critical link in the entire system, acting as a buffer and connection point between the upper and the outsole.

Two-Level Stitching

This construction uses two independent stitches. The first stitch connects the upper, the insole, and the welt together. The second stitch then attaches the outsole directly to the welt. This two-level system means the outsole is never stitched directly into the boot's upper.

The Cork Filling

The cavity created between the insole and the outsole is filled with a layer of granulated cork. This material provides cushioning, insulation, and breathability.

The Practical Benefits in a Work Environment

The specific mechanics of the Goodyear welt translate directly into tangible advantages on the job site.

Unmatched Durability

The dual-stitching method creates an incredibly strong and stable bond. The entire structure is interlocked, preventing the sole from delaminating or separating from the upper, even under high stress and torsion.

Superior Water Resistance

The welt acts as a physical barrier, preventing water from easily seeping into the seam where the upper meets the sole. While not fully waterproof, this construction offers significantly more protection against moisture than simpler methods.

The Power of Resoling

Because the outsole is stitched only to the welt, a cobbler can easily remove the old sole and stitch on a new one without disturbing the integrity of the upper. This means a high-quality pair of boots can be resoled multiple times, dramatically extending their service life.

Long-Term Customized Comfort

Initially firm, the cork footbed gradually compresses and molds to the unique shape of your foot with heat and pressure. Over time, this creates a personalized, supportive footbed that is more comfortable than a generic insole.

Understanding the Trade-offs

No construction method is perfect for every application. Objectivity requires acknowledging the downsides of a Goodyear welt.

The Initial Break-in Period

The robust materials and stiff construction result in a significant break-in period. The boots will feel firm and less flexible out of the box and require time to conform to your foot and gait.

Higher Upfront Cost

The complexity of the process and the quality of materials required make Goodyear welted boots more expensive than those with cemented or Blake-stitched soles. This is an initial investment in future longevity.

Increased Weight and Stiffness

The extra layers of material—the welt, the midsole, the cork—add weight and reduce the overall flexibility of the boot. For jobs requiring maximum agility or a lightweight feel, this can be a drawback.

Is a Goodyear Welt Right for Your Job?

Choosing the right boot construction depends entirely on your priorities and work environment.

- If your primary focus is maximum durability and long-term value: A Goodyear welt is the undisputed best choice, especially in rugged, abrasive conditions.

- If your primary focus is out-of-the-box comfort and flexibility: You may prefer a different construction, like a direct-attach or cemented sole, at the cost of repairability.

- If your primary focus is moisture protection in a wet environment: The water resistance of a Goodyear welt makes it a superior option to most other traditional constructions.

Ultimately, a Goodyear welt is the foundational choice for professional-grade work boots built to last.

Summary Table:

| Feature | Benefit | Ideal For |

|---|---|---|

| Dual-Stitch Construction | Exceptional durability & sole stability | Rugged, abrasive work environments |

| Welt Barrier | Enhanced water resistance | Wet conditions & job sites |

| Resolable Design | Extends boot life, reduces long-term cost | Professionals seeking value |

| Cork Footbed | Molds to foot shape for custom comfort | All-day wear & support needs |

Ready to Invest in Boots That Last?

As a large-scale manufacturer, 3515 produces comprehensive ranges of Goodyear welt work boots for distributors, brand owners, and bulk clients. Our production capabilities ensure superior craftsmanship, durability, and value—perfect for demanding work environments.

Contact us today to discuss your specific needs and discover how our footwear solutions can enhance your product line or supply chain.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.