The breaking-in period for military boots is a critical process of adaptation. It is essential for transforming a stiff, factory-made piece of equipment into a comfortable and reliable extension of your foot, preventing painful injuries and ensuring peak performance when it matters most.

Breaking in military boots is not about simply making them "softer." It is a deliberate process of molding rigid, protective materials to the unique anatomy of your feet to prevent mission-compromising issues like blisters and hot spots.

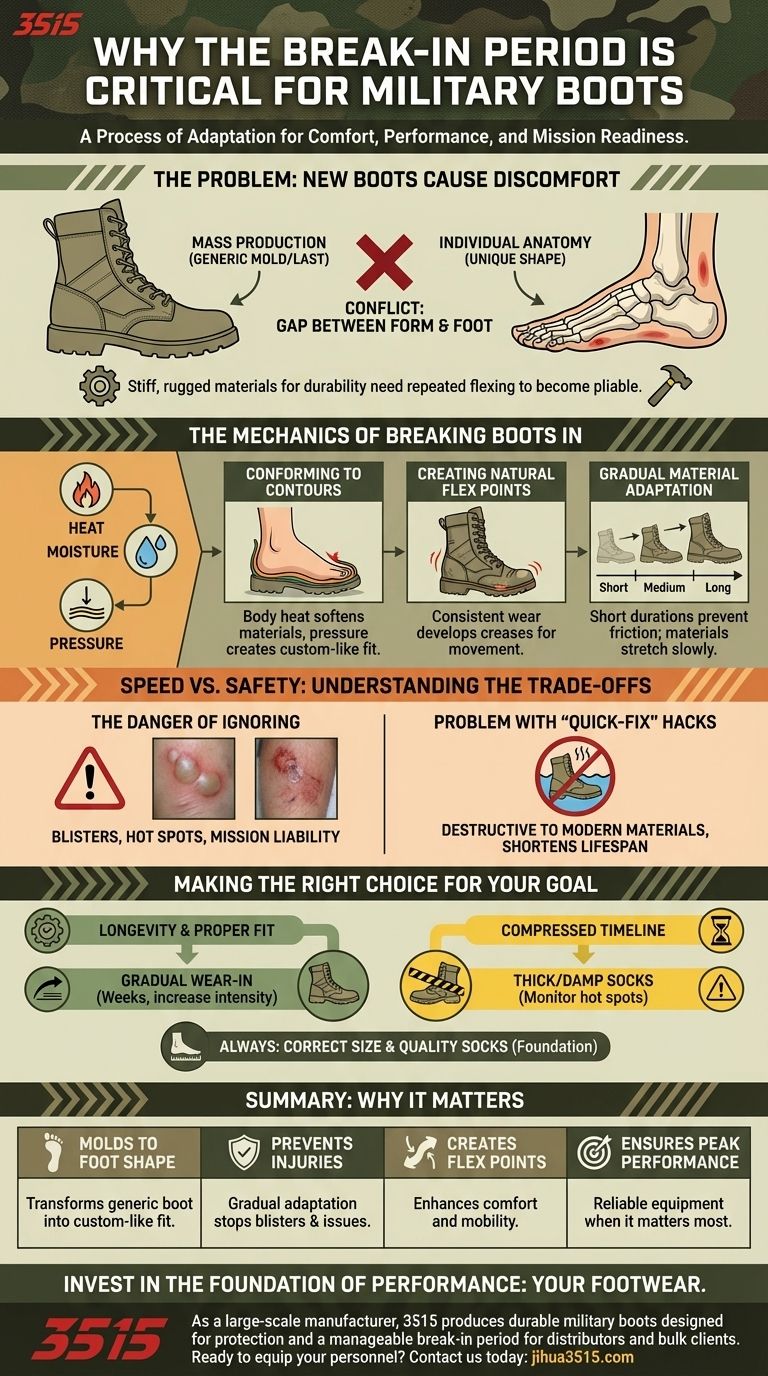

Why New Boots Cause Discomfort

A new pair of military boots is built for durability and protection, not immediate, out-of-the-box comfort. The initial stiffness and generic shape are the source of the problem.

The Conflict: Mass Production vs. Individual Anatomy

Military boots are manufactured on a standardized mold called a "last." This creates a uniform shape, while every individual's foot has a unique length, width, arch, and set of pressure points. The breaking-in period closes the gap between the boot's generic form and your specific foot shape.

The Role of Stiff Materials

These boots are constructed from rugged leather, dense synthetics, and other tough materials designed to withstand harsh conditions. This inherent rigidity is protective but requires a period of repeated flexing and pressure to become pliable in the right places.

The Mechanics of Breaking Boots In

The process of breaking in a boot involves physically altering its structure through wear. It's a combination of heat, moisture, and pressure from your foot.

Conforming to Your Foot's Contours

As you walk, your body heat softens the boot's materials. The pressure of your weight then gradually molds the footbed and leather to the specific contours of your arch, heel, and toes, creating a custom-like fit.

Creating Natural Flex Points

A new boot resists bending. Consistent wear forces the material at the ankle and across the ball of the foot to develop creases. These creases become the boot's natural flex points, allowing it to move with your foot instead of against it.

Gradual Material Adaptation

The key is gradual adaptation. Wearing boots for short durations at first allows the materials to stretch and conform slightly. This prevents the intense, prolonged friction that causes blisters and allows both your feet and the boots to adjust over time.

Understanding the Trade-offs: Speed vs. Safety

In an ideal world, you would have weeks to break in a new pair of boots. Rushing this process introduces significant risks that can compromise your effectiveness.

The Danger of Ignoring the Process

Failing to break in boots properly is the primary cause of severe blisters, chafing, and painful "hot spots." In a military or tactical environment, a foot injury is not a minor inconvenience; it is a liability that can impede movement and jeopardize safety.

The Problem with "Quick-Fix" Hacks

You may hear of methods like completely submerging boots in water and wearing them until they dry. While this can rapidly shape older, all-leather boots, it can be destructive to modern combat boots that use laminates, glues, and composite materials, potentially causing delamination and shortening the boot's lifespan.

Making the Right Choice for Your Goal

Your approach should be dictated by the boot's construction and your available timeline.

- If your primary focus is longevity and proper fit: Adhere to a gradual wear-in schedule, starting with an hour at a time indoors and slowly increasing the duration and intensity of activity over several weeks.

- If your timeline is compressed: Wear thick, slightly damp wool socks to help soften and stretch the leather, but stop immediately if you feel a hot spot forming to prevent blisters.

- For any new pair of boots: Always begin by ensuring you have the correct size and are using a quality sock system, as no amount of breaking in can fix a fundamentally poor fit.

Ultimately, treating the break-in period as a crucial part of your gear preparation is a direct investment in your own mission readiness and personal safety.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Molds to Foot Shape | Transforms a generic boot into a custom-like fit for your unique foot anatomy. |

| Prevents Injuries | Gradual adaptation prevents blisters, hot spots, and other painful foot issues. |

| Creates Flex Points | Allows the boot to move with your foot, enhancing comfort and mobility. |

| Ensures Peak Performance | A properly broken-in boot is a reliable piece of equipment when it matters most. |

Invest in the Foundation of Performance: Your Footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of durable military and tactical boots for distributors, brand owners, and bulk clients. Our expertise in material science and production ensures your team has access to boots designed for both protection and a manageable break-in period.

Ready to equip your personnel with reliable footwear built for the mission? Contact our team today to discuss your specific needs and volume requirements.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- How have United States military boots changed over time? From Heavy Leather to Versatile Modern Designs

- When do military personnel transition to combat boots? A Guide to Mission-Ready Footwear

- How do the heights of combat boots and jump boots differ? A Guide to Purpose-Built Footwear

- How often should military boots be maintained? A Proactive Guide to Maximize Boot Lifespan

- What are the drawbacks of jungle boots without a side zipper? A Guide to Trade-offs in Boot Design

- What are the drawbacks of Altberg jungle boots? High Cost, Lacing Issues & Quality Concerns

- Can combat boots be worn with a suit? A Guide to High-Risk, High-Reward Style

- What are the requirements for Navy boots? Essential Standards for Safety and Compliance