In short, slip resistance is critical because it directly mitigates one of the most common and costly causes of non-fatal injury in the workplace. Safety footwear with proper slip resistance provides the necessary grip and traction on wet, oily, or uneven surfaces, fundamentally preventing accidents before they happen.

The core purpose of slip-resistant footwear is not just to add grip, but to function as a critical safety system. It is engineered to actively manage the interface between the sole and the walking surface, reducing the risk of slips, trips, and falls which are a leading cause of preventable workplace injuries.

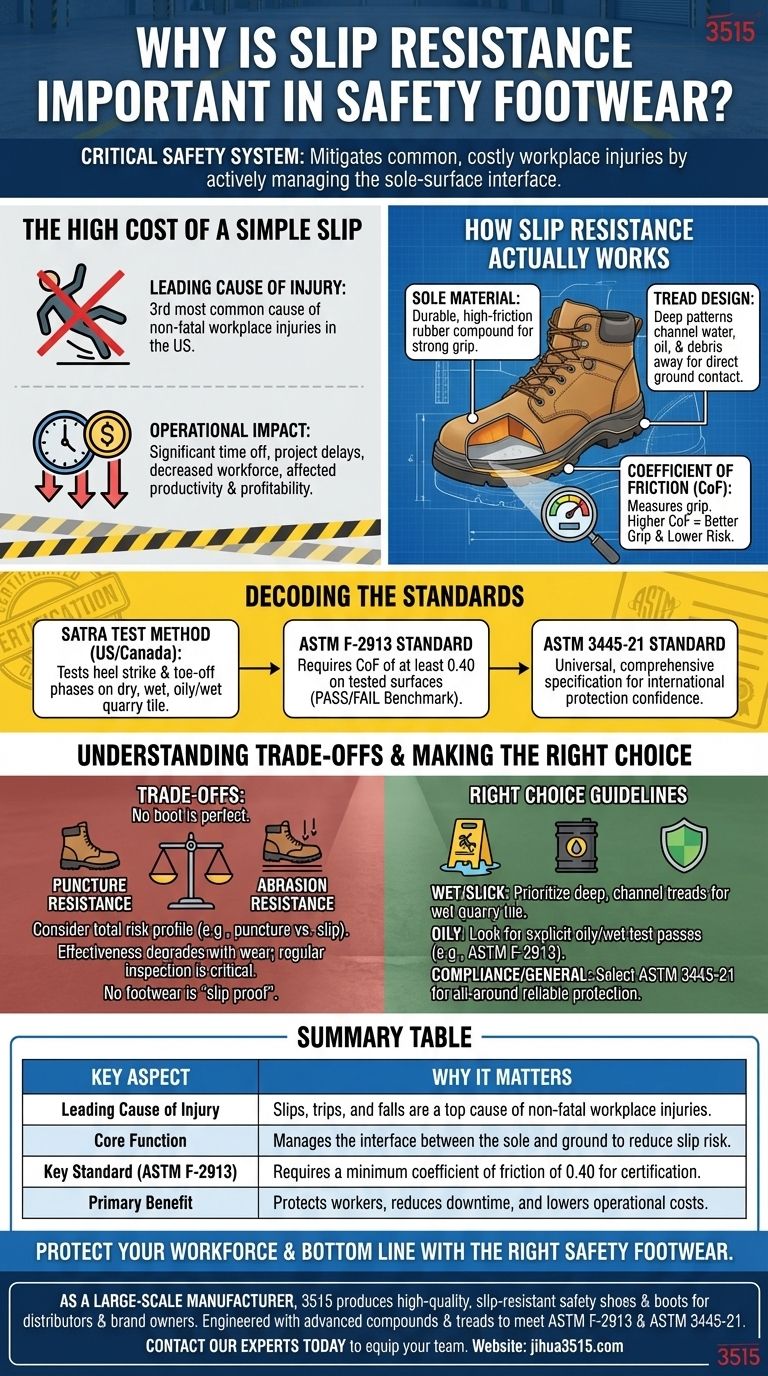

The High Cost of a Simple Slip

A slip might seem minor, but its cumulative impact on both personnel and operations is significant. Understanding this risk is the first step in appreciating the value of proper footwear.

A Leading Cause of Injury

Slips, trips, and falls are consistently ranked as the third most common cause of non-fatal work-related injuries in the United States.

These incidents are not just occasional mishaps; they are a frequent and predictable hazard in many industries.

The Impact on Operations

When an employee is injured, the consequences ripple through the business. It can lead to significant time off for the worker, project delays, and a temporarily decreased workforce, all of which affect productivity and profitability.

How Slip Resistance Actually Works

Effective slip resistance is not a single feature but the result of deliberate engineering, combining material science with functional design.

The Role of Sole Material

The foundation of a slip-resistant shoe is a sole made from a durable, high-friction material, typically a specialized rubber compound. This material is formulated to create a strong grip on a variety of surfaces.

The Importance of Tread Design

The pattern on the sole, or its tread, is just as important as the material. Deep, well-defined tread patterns are designed to channel water, oil, and other debris away from the bottom of the shoe.

This channeling action ensures that the sole makes direct contact with the ground, dramatically improving traction in slick conditions.

Measuring Performance: Coefficient of Friction

The effectiveness of slip resistance is measured scientifically by its coefficient of friction. This value quantifies the amount of grip a shoe has on a specific surface.

A higher coefficient of friction means better grip and a lower risk of slipping.

Decoding the Standards

To ensure reliability, safety footwear is tested against rigorous industry standards. These standards provide a clear benchmark for safety managers and workers.

The SATRA Test Methodology

In the United States and Canada, slip resistance is commonly evaluated using the SATRA test method. This process tests performance during both the heel strike and the toe-off phases of a person's stride.

The tests are conducted on multiple surfaces, including dry, wet, and oily/wet quarry tile, to simulate real-world conditions.

The ASTM F-2913 Standard

To pass the widely recognized ASTM F-2913 test, a shoe must achieve a coefficient of friction of at least 0.40 on the tested surfaces. This number serves as a critical pass/fail benchmark for performance.

The Universal Standard: ASTM 3445-21

The newer ASTM 3445-21 standard provides a more universal and comprehensive specification for slip resistance. It helps safety managers choose appropriate footwear with confidence, knowing it meets an internationally recognized level of protection.

Understanding the Trade-offs

Selecting the right safety footwear requires looking at the complete picture. No boot is perfect for every single hazard.

Slip Resistance vs. Other Protections

A boot with exceptional slip resistance may not have adequate puncture resistance from nails or abrasion resistance against rough materials. The total risk profile of the job site must be considered.

The Impact of Wear and Tear

The effectiveness of a slip-resistant sole degrades over time. As the tread pattern wears down, its ability to channel away liquids diminishes, and the shoe loses its grip. Regular inspection of footwear is a critical safety practice.

The Myth of "Slip Proof"

No footwear is truly "slip proof." The term "slip resistant" is used because these shoes are designed to significantly reduce the risk of slipping, not eliminate it entirely. User awareness and caution remain essential.

Making the Right Choice for Your Environment

Your specific work environment dictates which features are most critical. Use these guidelines to select the appropriate footwear.

- If your primary focus is wet or slick surfaces: Prioritize footwear with deep, channel-like treads specifically tested and rated for performance on wet quarry tile.

- If your primary focus is oily environments: Look for footwear that explicitly passes the oily/wet surface tests under standards like ASTM F-2913.

- If your primary focus is compliance and general safety: Select footwear that meets the comprehensive ASTM 3445-21 standard to ensure a reliable, all-around benchmark of protection.

Choosing the right slip-resistant footwear is a foundational investment in a proactive and effective safety culture.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Leading Cause of Injury | Slips, trips, and falls are a top cause of non-fatal workplace injuries. |

| Core Function | Manages the interface between the sole and ground to reduce slip risk. |

| Key Standard (ASTM F-2913) | Requires a minimum coefficient of friction of 0.40 for certification. |

| Primary Benefit | Protects workers, reduces downtime, and lowers operational costs. |

Protect your workforce and your bottom line with the right safety footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality, slip-resistant safety shoes and boots for distributors, brand owners, and bulk clients. Our footwear is engineered with advanced sole compounds and tread patterns designed to meet rigorous safety standards like ASTM F-2913 and ASTM 3445-21.

We can help you equip your team with durable footwear that provides the critical grip needed for wet, oily, and uneven surfaces.

Ready to enhance your safety program? Contact our experts today to discuss your specific needs and explore our production capabilities for all types of safety shoes and boots.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- Are composite toe boots puncture resistant? No, and here's why toe protection and sole safety are different.

- What materials are used in composite toe boots? Discover the Non-Metallic Safety Advantage

- What are the critical features to consider when selecting work shoes? A Guide to Safety, Comfort & Durability

- What core protective functions do Industrial-grade Safety Shoes provide? Key Foot Protection for High-Risk Environments

- What is the difference between S1 and S1P safety shoes? A Guide to Puncture-Resistant Protection

- What are safety shoes and what is their primary purpose? Essential PPE for Workplace Foot Protection

- How do safety shoes reduce fatigue and improve comfort for workers? Key Features for All-Day Support

- Why is the transmission of perceived competence vital in the sales of safety shoes? Building Trust Through Expertise