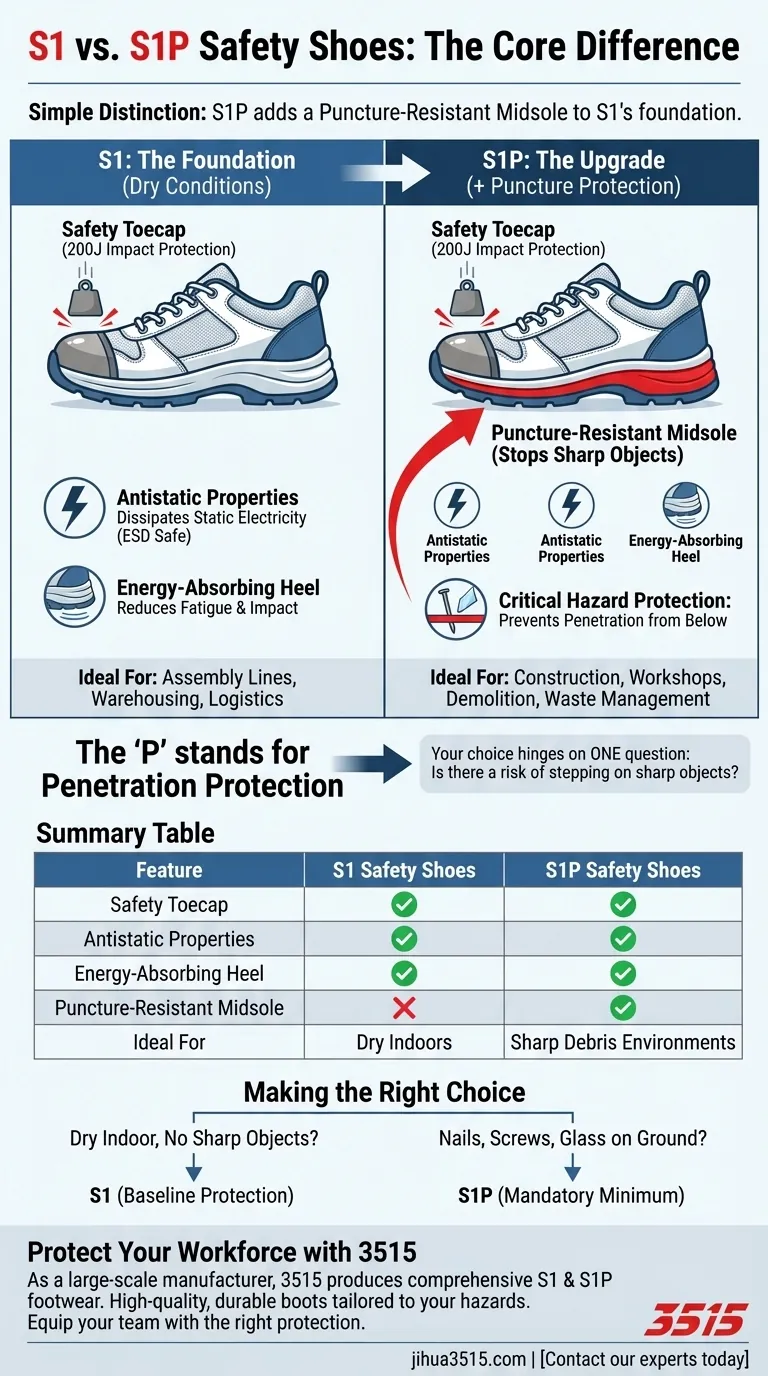

At its core, the difference is simple: S1P safety footwear includes all the features of the S1 standard, plus a crucial addition—a puncture-resistant midsole. The 'P' in S1P specifically denotes this protection against penetration from sharp objects like nails or glass from underfoot.

Your choice between S1 and S1P hinges entirely on one question: Is there any risk of stepping on sharp objects in your work environment? While both protect against basic impacts from the top, only S1P protects against hazards from below.

The Foundation: Understanding S1 Protection

The S1 rating represents the baseline standard for safety footwear designed for dry working conditions. It provides essential protection against common workplace risks.

Safety Toecap

All S1-rated footwear includes a protective toecap, typically made of steel or composite material. This component is tested to withstand an impact of 200 joules, shielding your toes from falling objects and compression.

Antistatic Properties

S1 shoes have antistatic soles that help to safely dissipate the body's static electricity. This is critical in environments where a sudden electrostatic discharge (ESD) could damage sensitive electronic components or ignite flammable materials.

Energy-Absorbing Heel

To reduce fatigue and minimize impact on your joints and back during long shifts, S1 footwear features an energy-absorbing heel region. This provides cushioning and stability with every step.

The Upgrade: What the 'P' in S1P Adds

The S1P rating builds directly upon the S1 foundation by incorporating one specific, vital feature.

Puncture-Resistant Midsole

The sole defining feature of S1P footwear is the puncture-resistant midsole. This is a protective layer, often made of steel or a flexible composite fabric, embedded within the sole of the shoe.

Critical Hazard Protection

This midsole is engineered to prevent sharp objects like nails, screws, metal shavings, or broken glass from penetrating the bottom of the shoe and injuring your foot.

Where S1P is Essential

This level of protection is non-negotiable in environments like construction sites, workshops, demolition zones, and waste management facilities, where floor debris is common.

Understanding the Trade-offs

Choosing between these two standards involves evaluating your environment against the capabilities of the footwear.

Protection vs. Perceived Comfort

The primary trade-off is risk. Opting for S1 footwear in an environment with puncture hazards is a significant safety failure. While an S1P midsole (especially steel) may add minimal weight or stiffness, modern composite options offer excellent flexibility.

The Cost of Safety

S1P footwear is typically priced slightly higher than its S1 equivalent due to the extra material and manufacturing process for the protective midsole. However, this marginal cost is insignificant when compared to preventing a serious foot injury.

Environmental Limitations

It is crucial to remember that both S1 and S1P are designed for dry work environments. Neither offers protection against water penetration. For wet conditions, you would need to look at S2 or S3-rated footwear.

Making the Right Choice for Your Goal

Your decision should be based solely on a clear assessment of your daily work environment and its specific hazards.

- If your primary focus is working in a dry indoor environment with no risk of sharp objects on the floor (e.g., assembly lines, warehousing, logistics): S1 footwear provides the required baseline protection against impact and static discharge.

- If your primary focus is working in any environment where nails, screws, glass, or other sharp debris could be on the ground (e.g., construction, manufacturing, auto repair): S1P is the mandatory minimum standard to ensure your safety.

Ultimately, assessing your environment accurately is the most critical step in protecting yourself from preventable injury.

Summary Table:

| Feature | S1 Safety Shoes | S1P Safety Shoes |

|---|---|---|

| Safety Toecap | Yes | Yes |

| Antistatic Properties | Yes | Yes |

| Energy-Absorbing Heel | Yes | Yes |

| Puncture-Resistant Midsole | No | Yes |

| Ideal For | Dry indoor environments (warehouses, logistics) | Environments with sharp debris (construction, workshops) |

Protect Your Workforce with the Right Safety Footwear

Choosing the correct safety standard is critical for workplace safety. As a large-scale manufacturer, 3515 produces a comprehensive range of S1 and S1P certified footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure high-quality, durable safety boots and shoes tailored to your specific industry hazards.

Let us help you equip your team with the right protection. Contact our experts today to discuss your requirements and receive a customized solution.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data