In short, seamless construction is critical because it eliminates the weakest points in a PVC work boot. Seams, created by stitching or gluing, introduce potential gateways for water and create stress points that are prone to tearing and failure under physical strain.

A work boot's primary function is to create an unbroken barrier between your foot and the environment. Seams are intentional breaks in that barrier, and seamless construction is the most effective way to ensure that barrier remains truly intact.

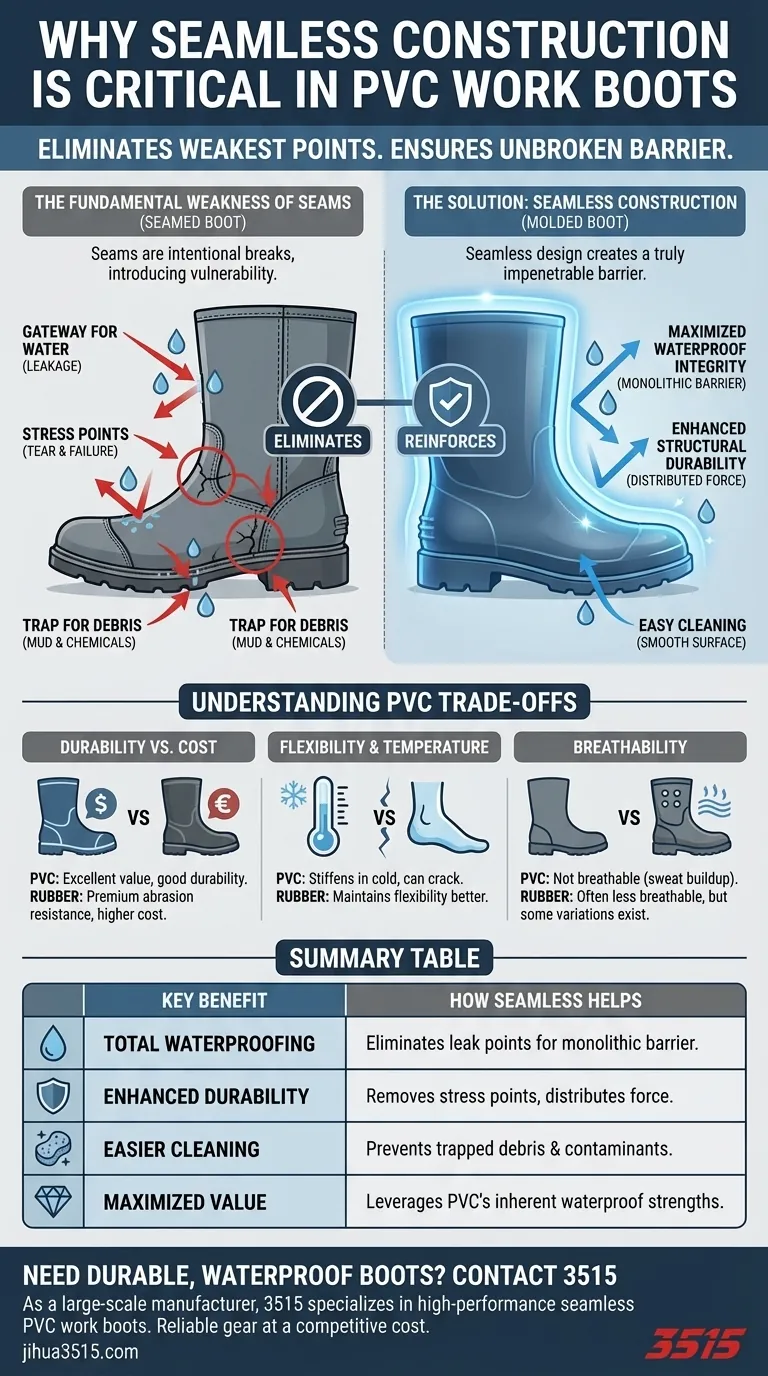

The Fundamental Weakness of Seams

Any seam, whether stitched or bonded, is an inherent vulnerability in a piece of protective gear designed to keep elements out. This is especially true for work boots subjected to constant flexing, abrasion, and moisture.

A Gateway for Water

The most obvious failure of a seam is leakage. Stitching creates hundreds of tiny perforations in the otherwise waterproof PVC material. While these may be sealed initially, constant movement and stress will eventually compromise the seal, allowing water ingress.

A Point of Mechanical Failure

Seams concentrate stress. When you walk, squat, or kick, the forces on the boot are not distributed evenly. A seam creates a rigid line where flexible materials meet, making it the most likely place for a tear or split to begin.

A Trap for Debris and Contaminants

External seams can trap mud, chemicals, and other worksite debris. This not only makes cleaning difficult but can also accelerate the degradation of the seam material itself, weakening the boot's overall structure over time.

How Seamless Construction Reinforces PVC's Strengths

Polyvinyl chloride (PVC) is chosen for work boots because it is naturally waterproof, lightweight, and inexpensive. Seamless construction methods, like single-pour injection molding, are designed to maximize these inherent benefits.

Maximizing Waterproof Integrity

A seamless, molded boot is a single, monolithic piece of PVC. There are no holes, no glued joints, and no stitched connections below the topline. This creates a truly impenetrable barrier against water, mud, and chemicals from the sole all the way up.

Enhancing Structural Durability

By eliminating seams, you eliminate the built-in stress points. Force is distributed more evenly across the entire surface of the boot. This makes the boot significantly more resistant to splitting when flexed or snagged, directly addressing one of PVC's primary material weaknesses.

Understanding the Trade-offs of PVC Boots

While seamless construction is a superior design, it's important to understand the limitations of the PVC material itself to make an informed decision.

Durability vs. Cost

Seamless construction makes a PVC boot far more durable than a seamed version. However, PVC as a material is generally less resistant to abrasion and puncture than premium vulcanized rubber. The key benefit of PVC remains its excellent performance for a much lower cost.

Flexibility and Temperature

PVC tends to become stiff and rigid in cold temperatures. A seamless design does not change this material property. In very cold environments, this stiffness can lead to cracking and reduced comfort.

Breathability

Like rubber, PVC is not a breathable material. This is essential for its waterproof quality but means moisture from sweat can build up inside the boot during extended wear.

Making the Right Choice for Your Goal

Selecting the right boot means matching its construction and material properties to your specific needs.

- If your primary focus is reliable waterproofing for wet, muddy, or chemical-rich environments: Seamless PVC construction provides the most dependable and cost-effective barrier.

- If your primary focus is long-term durability against constant abrasion and physical stress: You may want to consider a seamless boot made from a more robust material like high-grade rubber, though it will come at a higher cost.

- If your primary focus is comfort and flexibility in cold climates: Pay close attention to the boot's temperature rating, as standard PVC's stiffness can be a significant drawback.

Ultimately, choosing a seamless design ensures you are getting the maximum protective benefit that the PVC material has to offer.

Summary Table:

| Key Benefit | How Seamless Construction Helps |

|---|---|

| Total Waterproofing | Eliminates stitched or glued seams that can leak, creating a monolithic barrier. |

| Enhanced Durability | Removes stress points prone to tearing, distributing force evenly across the boot. |

| Easier Cleaning | Prevents debris and contaminants from getting trapped in external seams. |

| Maximized Value | Leverages PVC's inherent strengths (waterproof, low cost) by removing its weakest point. |

Need durable, waterproof work boots for your team?

As a large-scale manufacturer, 3515 specializes in producing high-performance seamless PVC work boots for distributors, brand owners, and bulk clients. Our seamless, injection-molded construction ensures maximum protection against water, chemicals, and physical stress, giving your customers reliable gear at a competitive cost.

Contact 3515 today to discuss your footwear needs and request a quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Why were traditional leather conditioners ineffective for firefighter boots? The Hidden Danger of Sealing vs. Breathing

- What should you look for to ensure boots are fully waterproof? The Essential 2-Part System

- How should one choose work shoes based on job responsibilities? Find the Perfect Fit for Your Workday

- In what work situations might cowboy boots not be appropriate? A Guide to Safety & Dress Code Compliance

- What should you check for when testing the fit of new work boots? Ensure All-Day Comfort and Safety

- What design features should be considered for additional protection and convenience in work boots? Enhance Your Safety and Comfort

- What safety features should be considered when selecting work boots? A Guide to Toe, Electrical & Slip Protection

- What safety boots are recommended for the transportation industry? Find the Perfect Fit for Your Role