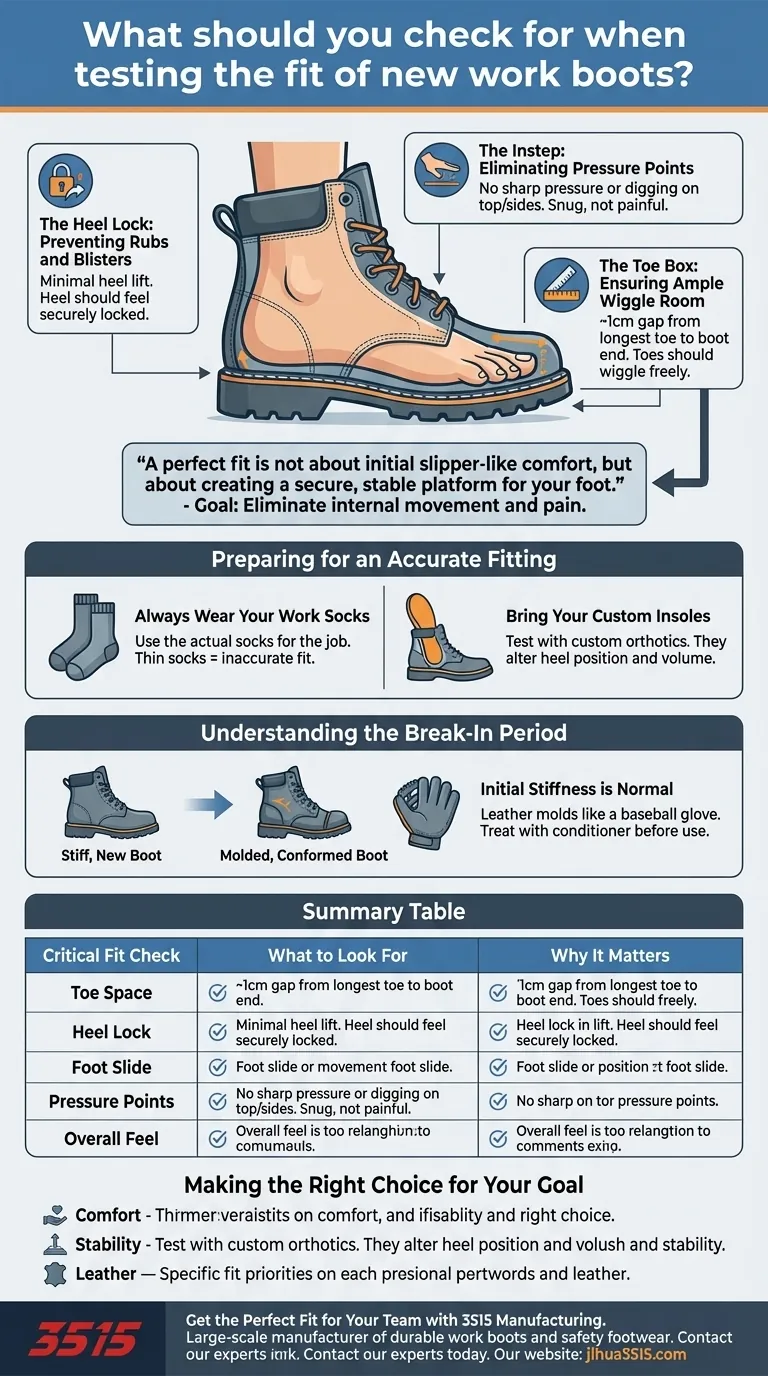

To properly test the fit of new work boots, you must check for five critical factors. Ensure there is about a centimeter of space between your longest toe and the end of the boot, your heel does not rub or lift excessively when you walk, your foot does not slide forward, and you feel no distinct pain or pressure points across your entire foot.

A perfect fit is not about initial slipper-like comfort, but about creating a secure, stable platform for your foot. The goal is to eliminate internal movement and pressure points that cause pain and fatigue over a long workday.

The Anatomy of a Proper Fit

A work boot isn't just footwear; it's a piece of equipment. Evaluating its fit requires a more detailed inspection than you would perform for a casual shoe. Each part of the boot must work with the anatomy of your foot.

The Heel Lock: Preventing Rubs and Blisters

The most critical area to check is the heel. While a very slight amount of heel lift can be acceptable in some new leather boots, your heel should feel securely "locked" into the back of the boot.

Excessive slipping or rubbing indicates a poor fit that will inevitably lead to painful blisters and instability on uneven ground.

The Toe Box: Ensuring Ample Wiggle Room

Your toes should never touch the end of the boot, even when walking downhill. A gap of about a thumb's width (roughly one centimeter) provides the necessary space for your foot to flex and swell slightly throughout the day.

You should be able to freely wiggle your toes. A cramped toe box restricts circulation and can cause significant discomfort over a full shift.

The Instep: Eliminating Pressure Points

Pay close attention to the top and sides of your foot. Run your fingers over the boot and press down, feeling for any areas where the boot digs in or creates a sharp point of pressure.

While a new leather boot should feel snug, it should not be painful. Sharp pressure points rarely improve with a break-in period and are a clear sign of an incompatible shape for your foot.

Preparing for an Accurate Fitting

Testing the fit is only effective if you replicate the exact conditions of your workday. Showing up to a fitting unprepared is the most common mistake buyers make.

Always Wear Your Work Socks

The thickness of your sock dramatically changes the volume of your foot. Always try on boots with the actual moisture-wicking or cushioned socks you wear on the job.

Testing with thin athletic socks will give you a completely inaccurate reading of the boot's true fit, leading you to buy a size that is too small.

Bring Your Custom Insoles

The factory insole that comes with a boot is often a simple foam placeholder. If you rely on custom orthotics or upgraded insoles for arch support, you must test the fit with them inside the boot.

A supportive insole can alter the position of your heel and reduce the boot's internal volume, making a proper test essential.

Understanding the Trade-offs: The Break-In Period

A brand-new work boot, especially one made of high-quality leather, will not feel perfect out of the box. You must distinguish between the discomfort of a poor fit and the expected stiffness of new materials.

Initial Stiffness is Normal

Stiff, full-grain leather requires a break-in period to soften and mold to the unique shape of your foot. The boot should feel snug and supportive, but not painfully tight.

Think of it like a high-quality baseball glove; its value comes from its ability to conform to you over time.

Treat Your Boots Before You Work

Before their first real use, new leather boots should be treated with a quality leather conditioner. This nourishes the leather, making it more pliable and accelerating the break-in process.

Applying a waterproofing agent afterward adds a crucial layer of protection against moisture and workplace chemicals, preserving the integrity of the fit you've established.

Making the Right Choice for Your Goal

Your specific job dictates which elements of the fit are most critical. Use your primary need to guide your final decision.

- If your primary focus is all-day comfort on hard surfaces: Prioritize correct toe spacing and ensure the boot can accommodate a high-quality, supportive insole.

- If your primary focus is stability on uneven terrain: Concentrate on achieving a secure heel lock and a snug fit around the ankle to prevent slipping.

- If you are buying stiff, full-grain leather boots: Accept that there will be an initial break-in period and focus on ensuring there are no severe, painful pressure points from the start.

Ultimately, the right work boot becomes an extension of your body, providing the foundation you need to perform your job safely and without distraction.

Summary Table:

| Critical Fit Check | What to Look For | Why It Matters |

|---|---|---|

| Toe Space | ~1 cm gap from longest toe to boot end | Prevents toe impact, allows for natural foot swelling |

| Heel Lock | Minimal heel lift or rubbing when walking | Prevents blisters and ensures stability on uneven ground |

| Foot Slide | Foot should not slide forward inside the boot | Maintains proper fit and prevents toe cramming |

| Pressure Points | No sharp pain or digging on the instep or sides | Avoids long-term discomfort and poor circulation |

| Overall Feel | Snug and secure, not slipper-like or painful | Creates a stable platform for safety and endurance |

Get the Perfect Fit for Your Team with 3515 Manufacturing

As a large-scale manufacturer, 3515 produces a comprehensive range of durable work boots and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, engineered for superior comfort, stability, and protection.

Let us help you equip your workforce with boots that provide the foundation for safe, distraction-free performance. Contact our experts today to discuss your specific needs and discover how our manufacturing solutions can benefit your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear