Beyond mere footwear, a work boot is a critical piece of personal protective equipment. Safety is its most vital attribute because its core function is to prevent serious, and potentially life-altering, injuries in hazardous environments. The specific safety features integrated into a boot, from its toe cap to its sole, are engineered to protect against direct threats that can range from heavy impacts and punctures to chemical burns and slips.

A work boot's primary function isn't durability or comfort—it's to act as the last line of defense between your feet and a serious workplace accident. Understanding its specific safety features is non-negotiable for ensuring your well-being.

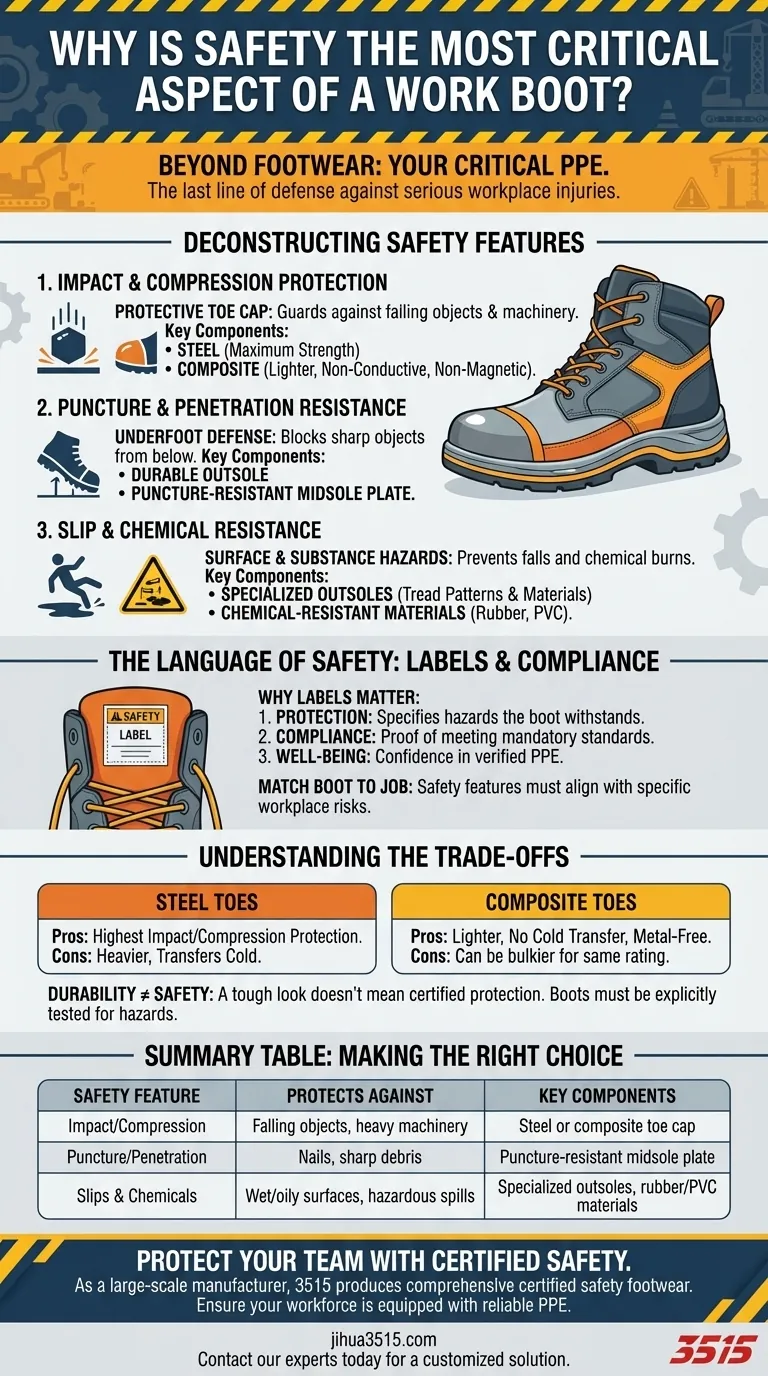

Deconstructing Work Boot Safety Features

A work boot achieves safety not through a single component, but through a system of protective features designed to counter specific workplace hazards.

Impact and Compression Protection

The most recognized safety feature is the protective toe cap. This component is crucial for guarding against injuries from falling objects or compression from heavy machinery.

These caps are typically made from steel for maximum strength or composite materials (like Kevlar, carbon fiber, or plastic) which are lighter and do not conduct electricity or temperature.

Puncture and Penetration Resistance

The bottom of your foot is just as vulnerable as your toes. Many hazards, such as loose nails or sharp scrap metal, pose a threat from the ground up.

A durable outsole offers the first layer of defense, but true protection comes from a puncture-resistant plate that is often embedded in the midsole.

Slip and Chemical Resistance

Slips, trips, and falls are among the most common workplace accidents. The boot's outsole is engineered with specific tread patterns and materials to provide traction on wet, oily, or uneven surfaces.

For environments with chemical hazards, boots made from specialized rubber or PVC can be certified as chemical-resistant, preventing harmful substances from penetrating the material and reaching the skin.

The Language of Safety: Labels and Compliance

The safety features of a work boot are meaningless without a way to verify them. This is where standardized labeling and compliance become essential.

Why Safety Labels Matter

A safety label on a boot is a clear declaration of its protective capabilities. It serves three critical functions:

- Protection: It tells you exactly which hazards (e.g., impact, electrical shock, puncture) the boot is rated to withstand.

- Compliance: It proves the boot meets the mandatory safety standards required by regulatory bodies and employers in many industries.

- Well-being: It gives you the confidence that you are wearing verified personal protective equipment (PPE).

Matching the Boot to the Job

Simply having a "work boot" is not enough. The safety features must align with the specific risks of your job. A boot designed for a construction site may not offer the necessary chemical resistance for a factory, and vice-versa.

Understanding the Trade-offs

Choosing the right work boot involves balancing different factors. Recognizing the inherent trade-offs is key to making an informed decision.

Steel vs. Composite Toes

The choice between a steel and a composite toe is a classic example. Steel toes often offer the highest level of protection against impact and compression.

However, composite toes are significantly lighter, don't transfer cold in winter, and are ideal for metal-free work environments. They may, however, be slightly bulkier to achieve the same safety rating as steel.

Durability Does Not Equal Safety

A common misconception is that any thick, durable boot is a safe boot. While high-quality materials like thick cowhide leather contribute to longevity, they do not automatically provide certified protection.

A boot must be explicitly tested and rated for specific hazards. Never assume a boot is safe simply because it looks and feels tough.

Making the Right Choice for Your Hazard

Your selection process should be driven entirely by the specific risks you face in your work environment.

- If your primary focus is protection from falling objects: Prioritize a boot with a certified steel or composite toe cap that meets impact and compression standards.

- If your primary focus is preventing punctures: Ensure the boot specifies a puncture-resistant plate in its construction.

- If your primary focus is avoiding slips or chemical exposure: Scrutinize the outsole's material and design, looking for explicit slip-resistant and chemical-resistant certifications.

Ultimately, choosing the right work boot is a direct investment in your personal safety and your ability to perform your job with confidence.

Summary Table:

| Safety Feature | Protects Against | Key Components |

|---|---|---|

| Impact/Compression | Falling objects, heavy machinery | Steel or composite toe cap |

| Puncture/Penetration | Nails, sharp debris | Puncture-resistant midsole plate |

| Slips & Chemicals | Wet/oily surfaces, hazardous spills | Specialized outsoles, rubber/PVC materials |

Protect your team with certified safety. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, engineered to meet rigorous standards for impact, puncture, and slip resistance. Ensure your workforce is equipped with reliable PPE – contact our experts today to discuss your specific needs and receive a customized solution.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What features should carpenters/builders look for in work boots? Essential Guide for Safety & Comfort

- What features should work boots have for cold or hot working conditions? A Guide to Temperature-Specific Safety

- Are water-resistant and water-repellent boots the same? A Guide to Choosing the Right Footwear

- What is a composite toe work boot? A Lightweight, Non-Metallic Safety Solution

- How should suede and nubuck leather work boots be cleaned? A Dry-Cleaning Guide to Preserve the Nap

- What are the key safety features to consider when choosing work boots? Ensure Maximum Protection for Your Job

- Are oil-resistant boots also waterproof? Don't Confuse These Two Critical Safety Features

- What are the key considerations when choosing work boots? Prioritize Safety, Durability, and Comfort