No, oil resistance and waterproofing are two distinct features in a boot. While a high-quality work boot may possess both characteristics, one does not automatically guarantee the other. Oil resistance refers to the outsole's ability to withstand degradation from petroleum-based substances, while waterproofing refers to the upper's ability to prevent water from entering the boot and reaching your foot.

The core misunderstanding is thinking of all "liquid protection" as the same. In reality, oil resistance protects the boot itself from chemical breakdown, ensuring its structural integrity and grip. Waterproofing protects your foot from environmental moisture, ensuring comfort and health.

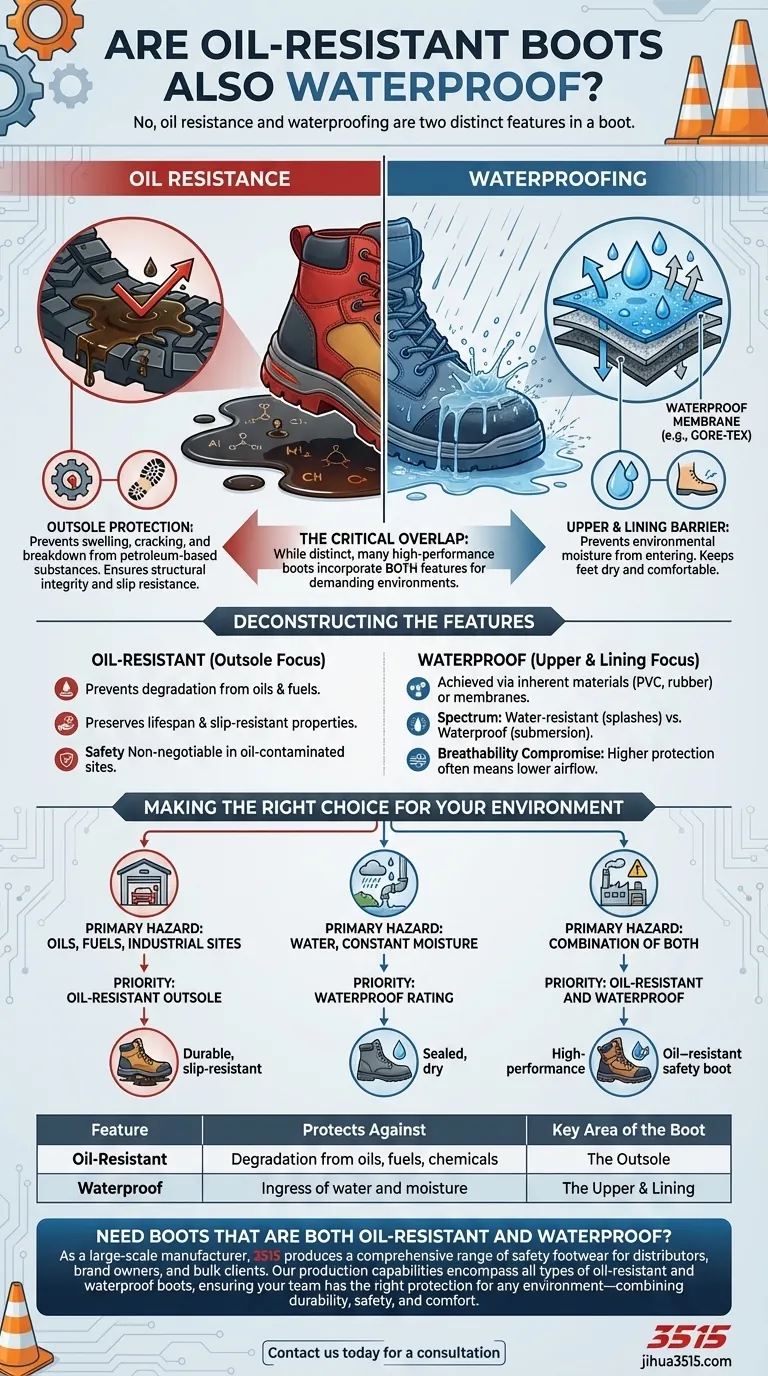

Deconstructing the Features: Oil vs. Water Protection

To select the right footwear, you must understand that these features are engineered to solve different problems in different parts of the boot.

What "Oil-Resistant" Truly Means

The oil-resistant rating applies specifically to the outsole—the part of the boot that contacts the ground.

Its purpose is to prevent oils, fuels, and other petroleum-based fluids from causing the sole's material to swell, crack, or break down. This preserves the boot's lifespan and, more critically, its slip-resistant properties on contaminated surfaces.

What "Waterproof" Actually Guarantees

Waterproofing, on the other hand, is about the boot's overall construction and its ability to act as a barrier against water.

This is typically achieved in two ways: through inherently waterproof materials like PVC or rubber, or by incorporating a waterproof membrane (like GORE-TEX) into the boot's lining. This membrane acts like a sock, preventing water from getting in while allowing sweat vapor to escape.

The Critical Overlap

While they are separate technologies, many boots designed for demanding industrial or outdoor environments will have both features.

A mechanic needs an oil-resistant sole to prevent slips and boot degradation, and they may also need waterproofing for washing down a bay. The key is to check the manufacturer's specifications for each feature explicitly. Never assume.

Understanding the Trade-offs

Choosing the right boot involves balancing protection with comfort and longevity. Each feature comes with its own set of considerations.

The Waterproofing Spectrum: Resistant vs. Proof

There is a significant difference between "water-resistant" and "waterproof."

Water-resistant boots can handle splashes or brief exposure to light rain but will eventually allow water to seep through, especially at the seams.

Waterproof boots are designed to withstand complete submersion for extended periods, featuring sealed seams and a non-porous membrane to ensure your feet stay completely dry.

The Breathability Compromise

The more waterproof a boot is, the less breathable it tends to be. A fully sealed rubber or PVC boot offers maximum water protection but will also trap sweat.

Modern breathable membranes like GORE-TEX mitigate this by allowing vapor to pass through, but even they cannot match the airflow of a non-waterproof boot made of leather or mesh.

The Safety Imperative of Oil Resistance

Failing to use an oil-resistant boot in the correct environment is a safety risk.

When a standard outsole is exposed to oil, it can soften and degrade rapidly, drastically reducing its traction. This makes slips and falls much more likely. Oil resistance is a non-negotiable feature for durability and safety in such conditions.

Making the Right Choice for Your Environment

Your specific work environment and its daily hazards should be the sole determining factor in your choice of footwear.

- If your primary focus is working in garages, machine shops, or industrial sites: Prioritize an oil-resistant outsole to ensure boot longevity and prevent slips on slick surfaces.

- If your primary focus is outdoor work, plumbing, or food production: Prioritize a "waterproof" rating with a sealed membrane or PVC construction to keep your feet dry from constant environmental moisture.

- If your primary focus is a combination of both hazards: Look for boots that are explicitly rated as both oil-resistant and waterproof, which is the standard for high-performance safety footwear.

Ultimately, reading the product specifications is the key to selecting footwear that provides the precise protection you need.

Summary Table:

| Feature | Protects Against | Key Area of the Boot |

|---|---|---|

| Oil-Resistant | Degradation from oils, fuels, and chemicals | The Outsole |

| Waterproof | Ingress of water and environmental moisture | The Upper & Lining |

Need boots that are both oil-resistant AND waterproof?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of oil-resistant and waterproof boots, ensuring your team has the right protection for any environment—combining durability, safety, and comfort.

Contact us today for a consultation and get the precise footwear solution you need.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health