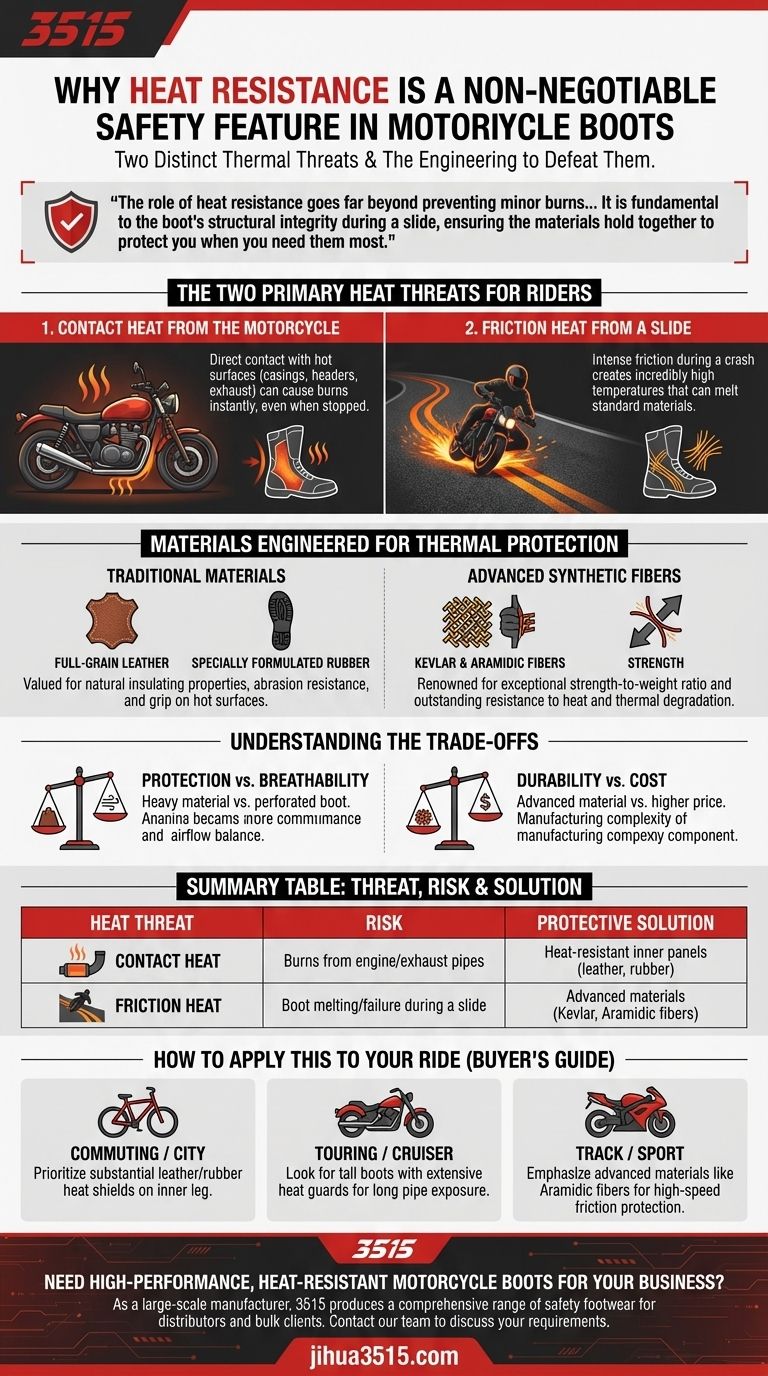

Heat resistance in motorcycle boots is a non-negotiable safety feature designed to protect you from two distinct thermal threats. It shields your lower legs from burns caused by contact with hot engine and exhaust components, and critically, it prevents the boot from melting or failing due to the intense friction generated during a crash.

The role of heat resistance goes far beyond preventing minor burns from a hot pipe. It is fundamental to the boot's structural integrity during a slide, ensuring the materials hold together to protect you when you need them most.

The Two Primary Heat Threats for Riders

A rider's lower legs are uniquely vulnerable to two different types of high-temperature events. Protective boots are engineered to handle both scenarios.

Contact Heat from the Motorcycle

The most obvious threat is direct contact with the motorcycle itself.

Engine casings, headers, and exhaust pipes can reach temperatures high enough to cause severe burns in an instant. This can happen while stopped in traffic, maneuvering the bike, or during an off-balance moment.

Tall boots with heat-resistant inner panels, often made of leather or rubber, create a crucial thermal barrier between your skin and these hot surfaces.

Friction Heat from a Slide

The second, and often more severe, thermal threat is the heat generated by friction.

When a rider slides across an asphalt or concrete surface during a crash, the friction can create incredibly high temperatures. A standard shoe or boot not designed for this would quickly melt, tear, or disintegrate.

Materials like high-grade leather, Kevlar, and Aramidic fibers are used precisely because they have a high melting point and resist thermal degradation, ensuring the boot remains intact and protective.

Materials Engineered for Thermal Protection

The effectiveness of a boot's heat resistance comes down to the materials used in its construction.

Traditional Leather and Rubber

Full-grain leather is a traditional material valued for its natural insulating properties and high resistance to heat and abrasion.

Specially formulated rubber compounds are also used, particularly on the inner calf and sole, to provide a heat shield against the bike and offer grip on hot surfaces.

Advanced Synthetic Fibers

Modern boots often integrate advanced synthetic materials for enhanced performance.

Kevlar and other Aramidic fibers are renowned for their exceptional strength-to-weight ratio and outstanding resistance to heat. These fibers are often used as an inner lining or in stitching to ensure the boot's seams don't fail under extreme friction and heat.

Understanding the Trade-offs

While essential, incorporating robust heat resistance involves balancing other design considerations.

Protection vs. Breathability

Thicker, more heat-resistant materials like heavy leather or multiple layers can reduce a boot's airflow and breathability. Manufacturers work to mitigate this with perforated zones or breathable membranes in areas less exposed to heat.

Durability vs. Cost

Boots that feature advanced materials like Aramidic fibers provide superior protection but often come at a higher price point. The cost reflects the research, development, and complex manufacturing required to integrate these high-performance components.

How to Apply This to Your Ride

Your ideal level of heat protection depends on your motorcycle and how you ride. Use these guidelines to make an informed choice.

- If your primary focus is daily commuting or city riding: Prioritize boots with substantial leather or rubber heat shields on the inner leg, as you'll frequently put your feet down near a hot engine.

- If your primary focus is long-distance touring or cruiser riding: Look for tall boots with extensive heat guards, as your legs may be positioned near exposed exhaust pipes for long durations.

- If your primary focus is track days or aggressive sport riding: Emphasize boots built with advanced materials like Aramidic fibers, as protection against friction heat in a high-speed slide is paramount.

Ultimately, choosing a boot with appropriate heat resistance is a direct investment in your safety and confidence on every ride.

Summary Table:

| Heat Threat | Risk | Protective Solution |

|---|---|---|

| Contact Heat | Burns from engine/exhaust pipes | Heat-resistant inner panels (leather, rubber) |

| Friction Heat | Boot melting/failure during a slide | Advanced materials (Kevlar, Aramidic fibers) |

Need high-performance, heat-resistant motorcycle boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of motorcycle boots and safety boots, engineered with advanced materials for superior thermal protection.

Contact our team today to discuss your requirements and discover how we can enhance your product line with durable, reliable footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- What are oil resistant safety boots? Your Guide to Slip-Resistant Footwear

- What is dielectric insulation in safety footwear? Essential Protection for High-Voltage Work

- What is metatarsal protection in safety boots? Essential Defense for Top-of-Foot Hazards

- What are the primary protective functions of professional-grade safety shoes? Enhance Safety in Heavy Industry

- What are the key differences between carbon fiber and composite-toe shoes? Choose the Best for Comfort & Safety

- What is the significance of impact resistance (IR) in safety boots? Protect Your Feet from Severe Injuries

- What role does standardized safety footwear play in high-intensity fall risk intervention studies? Ensuring Data Integrity & Participant Safety

- How should safety toe boots fit in terms of toe length? Achieve Maximum Comfort and Protection