At its core, an oil-resistant safety boot is specialized footwear engineered to maintain its structural integrity and protective qualities when exposed to oil. Unlike standard boots that can degrade, swell, or become dangerously slick, these boots use specific materials that resist oil, ensuring both the boot's longevity and the wearer's safety in demanding environments.

The primary function of an oil-resistant boot is not just to avoid being damaged by oil, but to preserve the grip and stability of its sole, which is the most critical factor in preventing slips and falls on contaminated surfaces.

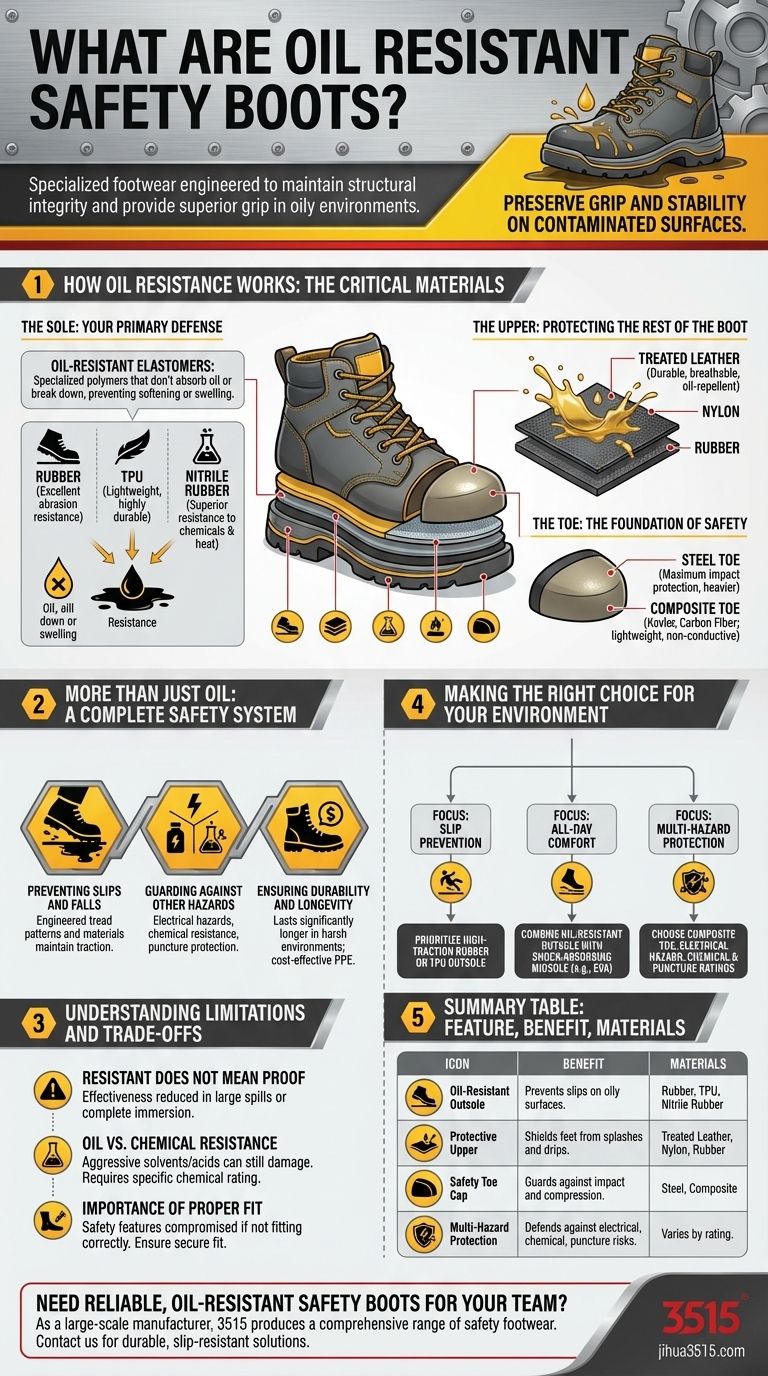

How Oil Resistance Works: The Critical Materials

A boot's ability to resist oil is determined by the specific compounds used in its construction, particularly in the outsole. These materials are chosen for their chemical stability when encountering hydrocarbons.

The Sole: Your Primary Defense

The outsole is the component in direct contact with hazardous surfaces. Its material composition is paramount.

Manufacturers use oil-resistant elastomers—specialized polymers that do not absorb oil or break down. This prevents the sole from softening, swelling, or losing its intended shape and grip.

Common high-performance sole materials include:

- Rubber: Offers excellent resistance to oil and abrasion, making it a durable choice for tough conditions.

- Thermo-Polyurethane (TPU): A modern material known for being lightweight yet highly durable and resistant to oils and chemicals.

- Nitrile Rubber: Often used in combination with other materials, Nitrile provides superior resistance to oils, chemicals, and high temperatures.

The Upper: Protecting the Rest of the Boot

While the sole provides slip resistance, the upper must protect your foot and withstand splashes and drips without weakening.

Materials like specially treated leather offer durability and breathability while repelling oil. For more intense exposure, synthetic materials like nylon or full rubber uppers provide a less porous barrier.

The Toe: The Foundation of Safety

The protective toe cap is a non-negotiable feature in a safety boot. Oil resistance complements this core function.

Steel toes offer maximum impact protection but are heavier. Composite toes are made from materials like Kevlar, carbon fiber, or plastic, providing excellent structural integrity at a much lighter weight and without conducting electricity.

More Than Just Oil: A Complete Safety System

Oil resistance is a key feature, but it functions as part of a broader system designed to protect you from a range of workplace hazards.

Preventing Slips and Falls

This is the most immediate benefit. Standard boot soles can become incredibly slick when they contact oil, but an oil-resistant sole is engineered with tread patterns and material properties designed to maintain traction.

Guarding Against Other Hazards

True safety boots are multi-functional. Look for ratings that indicate protection from electrical hazards, resistance to certain chemicals, and the ability to shield your feet from punctures or falling objects.

Ensuring Durability and Longevity

In an environment with oils and solvents, standard boots will break down rapidly. Investing in oil-resistant footwear ensures the boot will last significantly longer, making it a more reliable and cost-effective piece of personal protective equipment (PPE).

Understanding the Limitations and Trade-offs

To make an informed decision, you must understand what these boots can and cannot do. Objectivity is crucial for safety.

"Resistant" Does Not Mean "Proof"

Oil-resistant soles are designed to handle typical workplace exposure. However, in the event of a large spill or complete immersion, their effectiveness can be reduced, and a slip hazard may still exist.

Oil vs. Chemical Resistance

Oil resistance does not automatically equal broad chemical resistance. Aggressive solvents or acids can still damage the boot's sole and upper. If you work with substances like Sodium Hydroxide or Sulphuric Acid, you need a boot specifically rated for chemical resistance.

The Importance of Proper Fit

Safety features are compromised if the boot doesn't fit correctly. Sizing can differ between men's and women's models due to anatomical differences, so it is essential to try boots on and ensure a secure, comfortable fit.

Making the Right Choice for Your Environment

Select your boot based on the primary challenges of your specific job.

- If your primary focus is slip prevention in oily automotive or industrial settings: Prioritize a boot with a high-traction rubber or TPU outsole explicitly rated for oil resistance.

- If your primary focus is all-day comfort on hard surfaces: Look for a boot that combines an oil-resistant outsole with a shock-absorbing midsole made from materials like EVA (ethylene-vinyl acetate).

- If your primary focus is protection from multiple hazards: Choose a boot with a composite toe, electrical hazard rating, and verify if it carries additional ratings for chemical or puncture resistance.

Ultimately, choosing the right boot is a critical investment in your personal safety and daily performance.

Summary Table:

| Feature | Key Benefit | Common Materials |

|---|---|---|

| Oil-Resistant Outsole | Prevents slips on oily surfaces | Rubber, TPU, Nitrile Rubber |

| Protective Upper | Shields feet from splashes and drips | Treated Leather, Nylon, Rubber |

| Safety Toe Cap | Guards against impact and compression | Steel, Composite (Kevlar, Carbon Fiber) |

| Multi-Hazard Protection | Defends against electrical, chemical, and puncture risks | Varies by rating and design |

Need reliable, oil-resistant safety boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities include all types of oil-resistant boots and shoes designed for durability, slip resistance, and compliance with safety standards. Let us provide the right footwear solution for your workforce—contact us today to discuss your needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the primary functions of industrial-grade safety shoes? Protect Workers in Grinding & Cutting Operations

- In what way do assistive devices like crutches and protective footwear synergize during early-stage load management?

- What are the differences between safety, protective, and work shoes? Choose the Right Footwear for Your Job's Hazards

- What comfort features should a good safety shoe have? 5 Key Elements for All-Day Comfort

- How does the lacing system affect work shoes? Secure Fit, Stability & Safety

- Which is better, steel toe or composite toe boots? Match Your Job's Hazards for Optimal Safety

- What are the design advantages of using safety shoes for smart wearable tech? Build Rugged Data Platforms.

- What is the value of using high-precision timing for obstacle walk tests in safety shoes? Data-Driven Agility Design