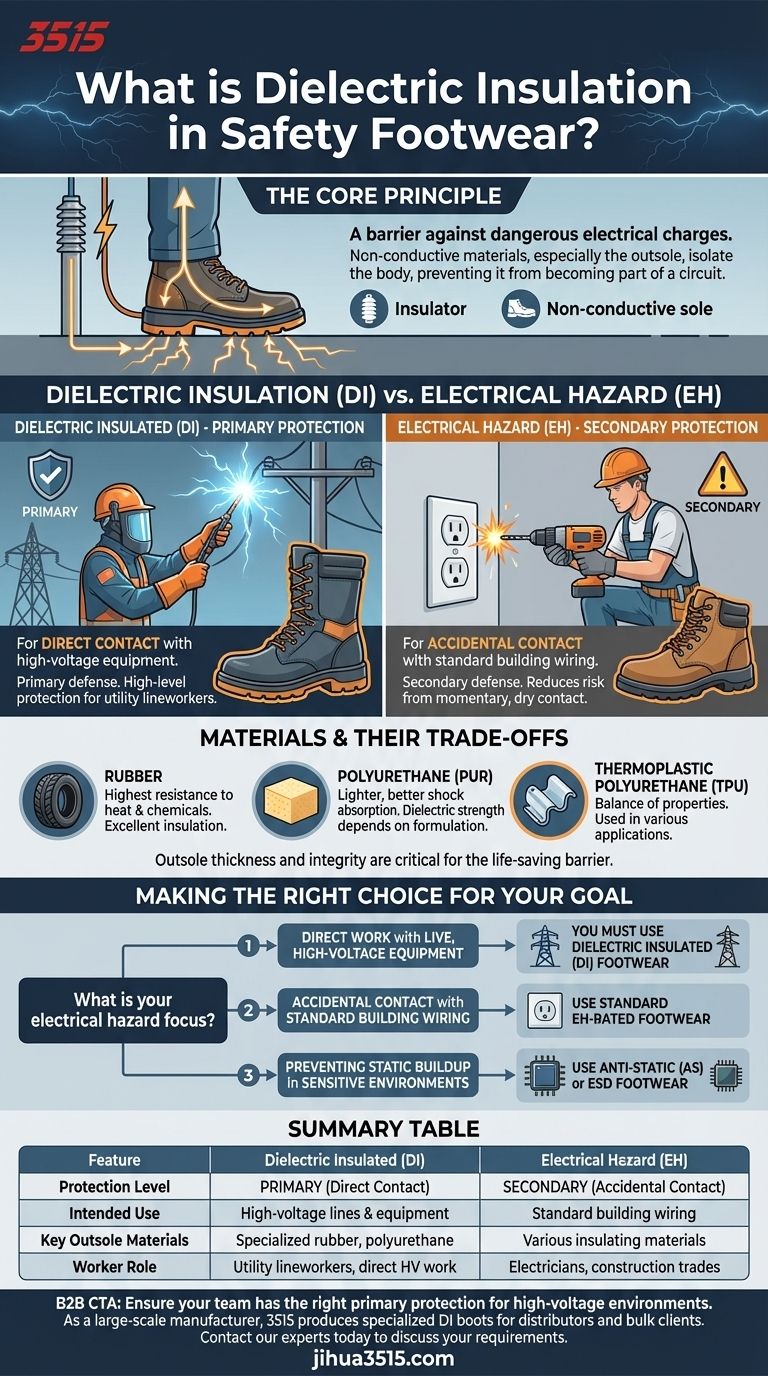

In safety footwear, dielectric insulation is a specialized, high-level form of protection designed to prevent the flow of electricity through the wearer. It provides a barrier against dangerous electrical charges, offering a significantly higher degree of safety than standard Electrical Hazard (EH) rated boots, and is critical for those working directly with live electrical currents.

The crucial distinction is that standard Electrical Hazard (EH) footwear offers secondary protection against accidental contact with a live circuit, while Dielectric Insulated (DI) footwear is a primary means of protection for those who work in direct contact with high-voltage equipment.

The Principle of Dielectric Protection

To understand its importance, we must first clarify what "dielectric" means and how it functions in a safety boot.

What Makes a Material "Dielectric"?

A dielectric material is simply an electrical insulator. It does not conduct electricity.

When used in footwear, these non-conductive materials create a barrier that isolates your body from the ground, preventing it from becoming part of an electrical circuit.

How the Boot Provides Protection

The entire construction, but especially the outsole, is made from materials with extremely high electrical resistance, such as specialized rubber or polyurethane compounds.

If you touch a live electrical source, the boot's thick, non-conductive sole stops the current from passing through you to the ground, which would otherwise cause severe injury or electrocution.

Dielectric vs. Electrical Hazard (EH): The Critical Difference

Confusing these two ratings is a common and dangerous mistake. The level of protection they offer is fundamentally different and intended for different work environments.

Electrical Hazard (EH) Footwear

EH-rated footwear is the most common type of electrical protection found in safety boots.

It is considered a secondary source of protection. Its purpose is to reduce the risk from accidental, momentary contact with live electrical circuits under dry conditions.

Dielectric Insulated (DI) Footwear

DI footwear is a highly specialized and far less common category. It serves as a primary source of protection.

It is designed for workers, such as utility lineworkers, who are expected to work in close proximity to or in direct contact with high-voltage power lines and equipment.

Materials and Their Trade-offs

The performance of electrically insulating footwear is entirely dependent on the materials used in its outsole.

The Role of the Outsole

The outsole is the single most critical component for electrical resistance. The thickness and integrity of this layer are what provide the life-saving barrier.

Common Outsole Materials

Outsoles are typically made from polyurethane (PUR), thermoplastic polyurethane (TPU), or rubber. Each offers a different balance of properties.

Rubber generally provides the highest resistance to heat and chemicals in addition to its excellent insulating properties.

Polyurethane (PUR) is often lighter and offers better shock absorption and comfort, but its specific formulation determines its dielectric strength.

Making the Right Choice for Your Goal

Selecting the correct footwear is not just a matter of compliance; it is a critical safety decision. Your choice must be based entirely on the specific electrical hazards present in your work environment.

- If your primary focus is secondary protection against accidental contact with standard building wiring: Standard EH-rated footwear is the appropriate and required choice for most electricians and construction trades.

- If your primary focus is direct work with live, high-voltage equipment like power lines: You must use specialized Dielectric Insulated (DI) footwear as a primary line of defense.

- If your primary focus is preventing static buildup in sensitive electronic environments: You need a completely different category, such as Anti-Static (AS) or Electro-Static Dissipative (ESD) footwear.

Understanding the distinction between these protection levels empowers you to select the precise equipment needed to ensure your safety on the job.

Summary Table:

| Feature | Dielectric Insulated (DI) | Electrical Hazard (EH) |

|---|---|---|

| Protection Level | Primary (Direct Contact) | Secondary (Accidental Contact) |

| Intended Use | High-voltage lines & equipment | Standard building wiring |

| Key Outsole Materials | Specialized rubber, polyurethane | Various insulating materials |

| Worker Role | Utility lineworkers, direct HV work | Electricians, construction trades |

Ensure your team has the right primary protection for high-voltage environments.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities include specialized Dielectric Insulated (DI) boots designed for maximum safety when working directly with live electrical equipment.

Contact our experts today to discuss your specific dielectric insulation requirements and request a quote.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What role do high-resolution industrial cameras play in the identification of safety shoes? Enhancing Site Safety

- Why are industrial-grade safety shoes critical for reducing workplace injuries? Key Insights for Construction Safety

- Why is the use of professional safety shoes with chemical resistance essential during Mixed Bed Polisher regeneration?

- Why is choosing the right safety shoes important? Mitigate Workplace Hazards and Boost Productivity

- Are there firefighter boots available for children? Discover Safe & Fun Costume Boots

- What materials are used in composite toe boots? Discover the Non-Metallic Safety Advantage

- How do motorcycle boots enhance safety for riders? Protect Your Feet from Impact, Abrasion & Twists

- What are safety shoes designed to protect against? A Complete Guide to Workplace Foot Protection