Choosing the right work boot is a critical safety decision, not a style choice. The importance lies in aligning the boot’s protective features directly with the specific, unique hazards of your industry. A boot designed for a construction site offers little protection against the electrical risks an electrician faces, just as an electrician's boot may fail on a slippery factory floor. Proper footwear is your primary line of defense against injury and a key factor in maintaining comfort and productivity throughout a demanding workday.

Your work boot isn't just another piece of equipment; it's a personalized safety system. The core task is to conduct a simple risk assessment of your job site and then match those specific hazards—impact, puncture, electricity, slips—to the certified features of the boot.

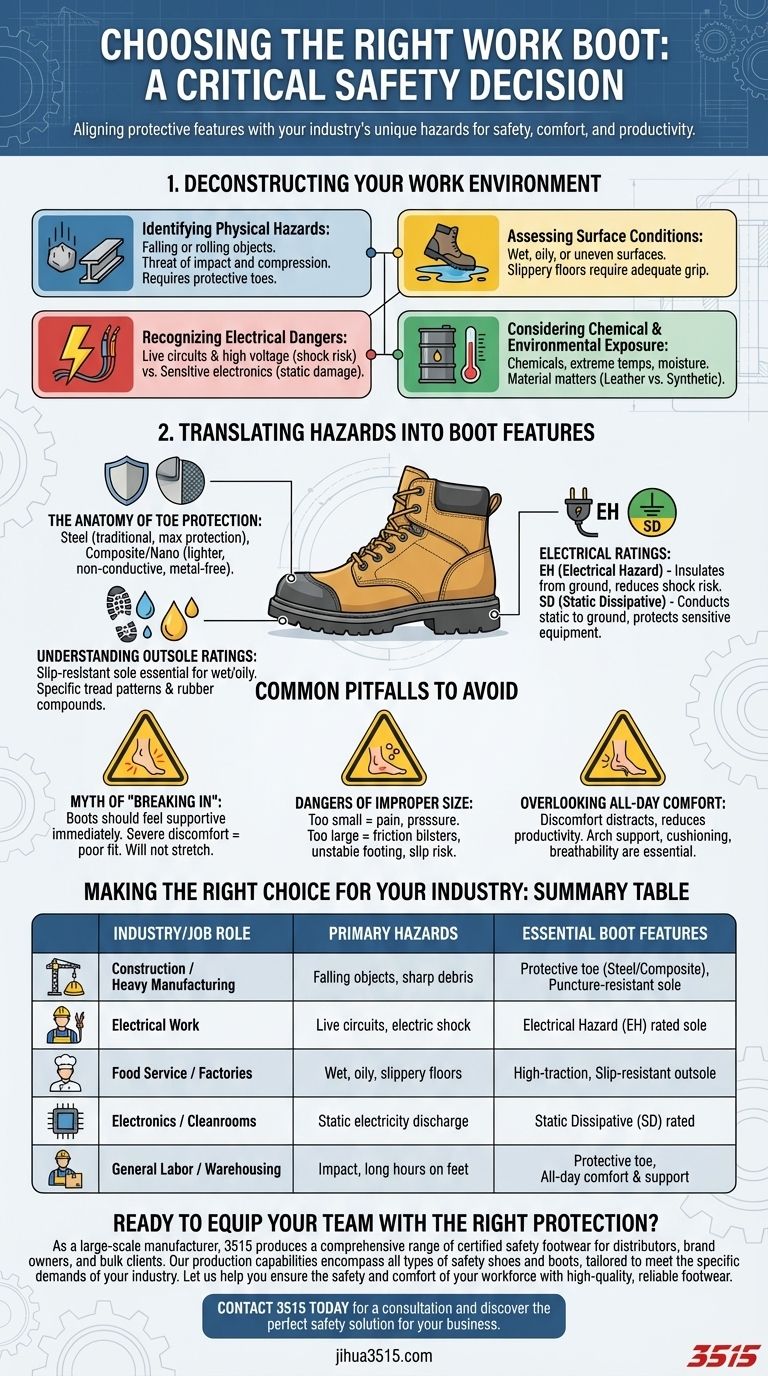

Deconstructing Your Work Environment

To select the right boot, you must first systematically analyze the environment where you work. Every feature of a quality work boot is designed to counteract a specific type of on-the-job risk.

Identifying Physical Hazards

The most common risks on many job sites are from falling or rolling objects. This threat of impact and compression is why protective toes were invented.

Consider the weight and type of materials you handle. Heavy machinery, building materials, or dense tools all pose a significant threat to your feet.

Assessing Surface Conditions

Look at the ground you walk on for most of your shift. Is it consistently wet, oily, or uneven?

Slippery surfaces are a leading cause of workplace injuries. A standard sole will not provide adequate grip on floors with oil, water, or chemical residue.

Recognizing Electrical Dangers

Working near live circuits, wiring, or high-voltage equipment introduces the invisible danger of electric shock.

Conversely, some environments with sensitive electronic components require you to dissipate static electricity from your body to prevent damage to the equipment. These two scenarios require fundamentally different types of protective footwear.

Considering Chemical and Environmental Exposure

The materials your boots are made of directly impact their performance against environmental factors. You must consider exposure to chemicals, extreme temperatures, and moisture.

Leather offers excellent durability and breathability for general use, while synthetic materials often provide superior resistance to specific chemicals, acids, and water.

Translating Hazards into Boot Features

Once you have identified the risks, you can match them to the corresponding safety features. These features are often certified to meet specific safety standards.

The Anatomy of Toe Protection

Protective toe caps are the most well-known safety feature. They are typically made from steel, composite materials, or nano-composites.

Steel is the traditional standard, offering maximum protection. Composite and nano-toes are lighter, do not conduct heat or cold, and will not set off metal detectors.

Understanding Outsole Ratings

The outsole is your connection to the ground. A slip-resistant sole is essential for wet or oily environments.

These soles are designed with specific tread patterns and rubber compounds that channel liquids away and maintain a firm grip on the surface.

Electrical Hazard (EH) vs. Static Dissipative (SD)

These ratings are critical and mutually exclusive. An Electrical Hazard (EH) rated boot is built to insulate you from the ground, reducing the chance of electric shock.

A Static Dissipative (SD) boot does the opposite. It is designed to safely conduct static electricity from your body to the ground, protecting sensitive electronic equipment from damage.

Common Pitfalls to Avoid

Selecting the wrong boot, or even the right boot in the wrong size, can negate its safety features and create new health problems.

The Myth of "Breaking In" a Bad Fit

A work boot should feel supportive and secure from the moment you put it on. Severe discomfort is a sign of a poor fit, not a boot that needs to be "broken in."

Boots that are too small will never stretch enough to be comfortable, leading to constant pain and pressure points.

The Dangers of an Improper Size

An incorrect fit is more than just uncomfortable; it's a safety liability. Ill-fitting boots are a direct cause of blisters, bunions, and foot pain like cuboid syndrome.

Boots that are too large are equally problematic. Your foot will slide inside, causing friction blisters and an unstable footing that increases the risk of slips and falls.

Overlooking All-Day Comfort

Safety features are useless if the boot is too painful or fatiguing to wear for a full shift. Discomfort leads to distraction and can reduce productivity.

Proper arch support, cushioning, and breathability are not luxuries; they are essential components that allow you to focus on your work safely.

Making the Right Choice for Your Industry

Your selection process should be guided by the single most significant risk you face daily. Use your primary job function to determine your non-negotiable feature.

- If your primary focus is construction or heavy manufacturing: Prioritize certified toe protection (steel or composite) and a puncture-resistant sole.

- If your primary focus is electrical work: A certified Electrical Hazard (EH) rating is your most critical safety feature.

- If your primary focus is in wet or oily environments: Select a boot with the highest-rated slip-resistant outsole available.

- If your primary focus is working with sensitive electronics: Ensure your boot is rated for Static Dissipative (SD) properties to protect your equipment.

Ultimately, investing in the correct footwear is a direct investment in your personal safety, long-term health, and professional performance.

Summary Table:

| Industry/Job Role | Primary Hazards | Essential Boot Features |

|---|---|---|

| Construction / Heavy Manufacturing | Falling objects, sharp debris | Protective toe (Steel/Composite), Puncture-resistant sole |

| Electrical Work | Live circuits, electric shock | Electrical Hazard (EH) rated sole |

| Food Service / Factories | Wet, oily, slippery floors | High-traction, Slip-resistant outsole |

| Electronics / Cleanrooms | Static electricity discharge | Static Dissipative (SD) rated |

| General Labor / Warehousing | Impact, long hours on feet | Protective toe, All-day comfort & support |

Ready to Equip Your Team with the Right Protection?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, tailored to meet the specific demands of your industry.

Let us help you ensure the safety and comfort of your workforce with high-quality, reliable footwear.

Contact 3515 today for a consultation and discover the perfect safety solution for your business.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the differences between high-cut and low-cut PVC work boots? Choose the Right Protection for Your Job

- What are the main types of work boots? Find the Perfect Fit for Your Job's Hazards

- Why are pull on work boots recommended for ranch workers? Unmatched Safety, Speed & Cleanability

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions

- What are electrical hazard (EH) rated work boots? Essential Secondary Protection for High-Risk Jobs

- What industries or work environments are these boots suitable for? Find Your Perfect Fit

- What causes blisters in work boots? The Real Culprits Behind Foot Pain

- What are the characteristics of synthetic/leather boots? Modern Performance Meets Lightweight Durability