At its core, a blister from a work boot is a defense mechanism. It's your body's response to intense, localized friction that damages the outer layers of your skin, prompting it to create a fluid-filled cushion to protect the deeper tissue from further harm. This friction is almost always caused by an improper fit, excessive moisture, or the stiffness of a new, unbroken-in boot.

The central issue isn't just the boot or your foot; it's the entire system. Blisters form when the relationship between your foot, your sock, and your boot is out of sync, turning normal movement into a source of damaging friction.

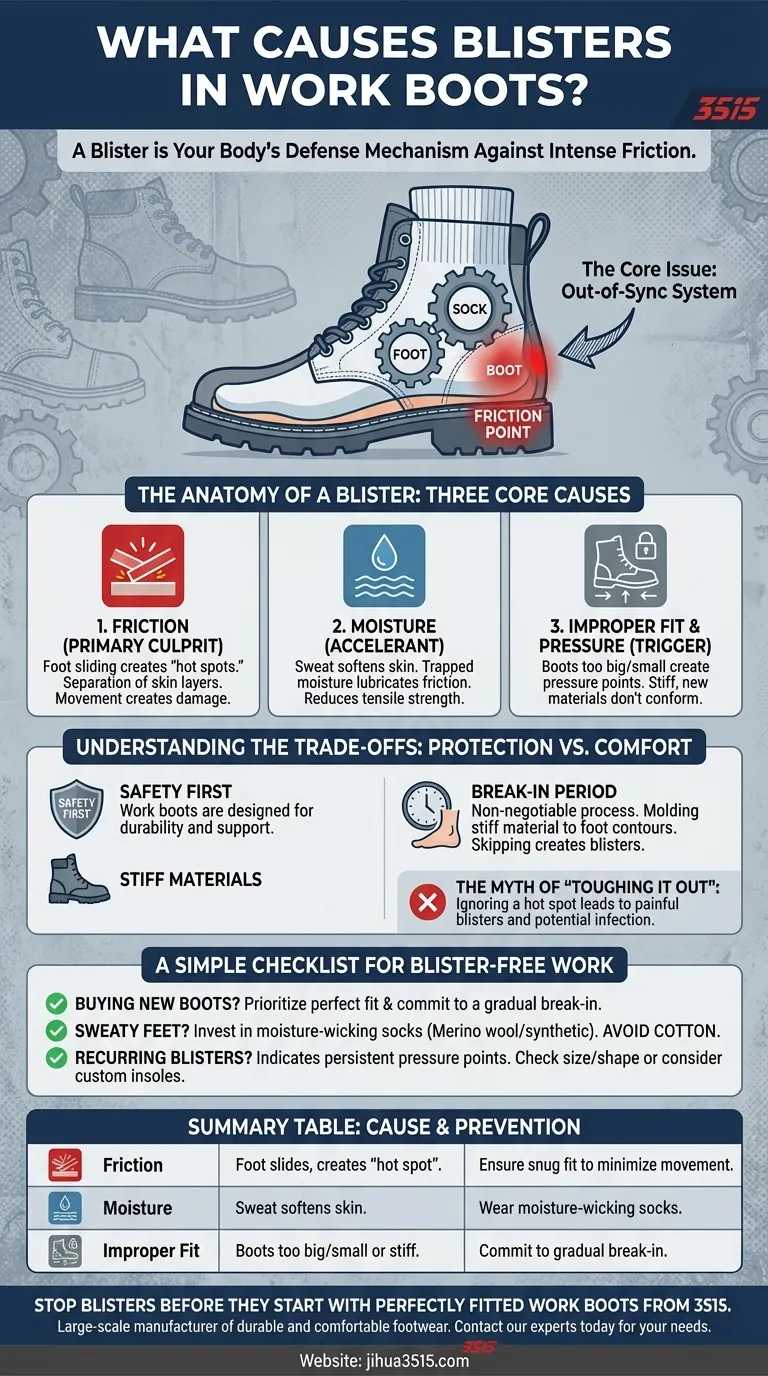

The Anatomy of a Blister: Three Core Causes

To prevent blisters, you must first understand the specific conditions that create them. It's rarely a single issue but rather a combination of factors working together against your skin.

The Primary Culprit: Friction

Friction is the direct mechanical force that causes a blister. Your foot can move slightly inside your boot with every step you take.

When this movement is excessive or focused on one spot, the repeated rubbing separates the top layers of skin from the layers beneath. This creates what is commonly known as a hot spot—the first warning sign.

The Accelerant: Moisture

Moisture, primarily from sweat, dramatically worsens the effects of friction. Wet skin is significantly softer and has less tensile strength than dry skin.

This softened skin is far more susceptible to tearing and damage from rubbing. A sock that traps moisture against your foot essentially lubricates the path for friction to do its work more quickly and severely.

The Trigger: Improper Fit & Pressure Points

An improperly sized boot is the most common trigger for friction and pressure. A boot that is too large allows your foot to slide, creating friction. A boot that is too small pinches and creates intense pressure points.

Stiff materials in new boots, especially leather, don't yet conform to the unique shape of your foot. This creates specific high-pressure areas—typically on the heel, ankle, or toes—that become the focal point for blisters.

Understanding the Trade-offs: Protection vs. Comfort

Work boots are designed for safety first, which often involves materials and construction methods that can be at odds with immediate, out-of-the-box comfort.

The "Break-In" Period is Non-Negotiable

New boots, particularly high-quality leather ones, are intentionally stiff. This stiffness provides essential ankle support and durability.

The break-in period is the necessary process of your body heat and the pressure of your movement slowly molding this stiff material to the specific contours of your feet. Skipping this is the single biggest cause of blisters in new boots.

The Myth of "Toughing It Out"

Many believe that pushing through the pain of a hot spot will "toughen" the skin. This is a critical mistake.

A hot spot is a clear signal that skin damage is actively occurring. Ignoring it and continuing to work will almost certainly result in a painful blister that can take days or weeks to heal, potentially putting you at risk of infection.

A Simple Checklist for Blister-Free Work

True prevention is about controlling the environment inside your boot. By managing fit, moisture, and friction proactively, you can eliminate the problem before it starts.

- If you are buying new boots: Prioritize a perfect fit above all else and commit to a gradual break-in period, wearing them for just a few hours a day at first.

- If you struggle with sweaty feet: Invest in high-quality, moisture-wicking socks made from merino wool or synthetic blends and avoid cotton at all costs.

- If you get recurring blisters in the same spot: This indicates a persistent pressure point. Your boots may be the wrong size or shape for your feet, or you may need to see a podiatrist about custom insoles.

Ultimately, preventing blisters is about treating your feet as essential professional equipment.

Summary Table:

| Cause | Why It Happens | Key Prevention Tip |

|---|---|---|

| Friction | Foot slides inside the boot, creating a 'hot spot'. | Ensure a snug, proper fit to minimize movement. |

| Moisture | Sweat softens skin, making it more prone to damage. | Wear moisture-wicking socks (avoid cotton). |

| Improper Fit | Boots are too big/small or are new and stiff. | Commit to a gradual break-in period for new boots. |

Stop blisters before they start with perfectly fitted work boots from 3515.

As a large-scale manufacturer, we produce a comprehensive range of durable and comfortable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed with the right fit and materials to minimize break-in time and maximize comfort.

Let us help you equip your team with footwear that protects without causing pain. Contact our experts today to discuss your needs and get a quote.

Visual Guide

Related Products

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- How can moc toe boots be styled for formal occasions? Elevate Your Smart Casual Look

- How can you fix a boot zipper that has come off? A Step-by-Step Guide to a Quick Repair

- What work boot features are essential for warehouse and light industrial settings? Prioritize Lightweight Protection & All-Day Comfort

- What options are available for restoring worn-out work boots? Expert Strategies for Longevity

- What should you check for when testing the fit of new work boots? Ensure All-Day Comfort and Safety

- What are the key features for warehouse and logistics work boots? Ensure Safety and All-Day Comfort

- What is the primary purpose of lace-to-toe boots? Achieve a Perfect, Customizable Fit

- What is the significance of waterproof and chemical resistance in firefighting boots? Essential Protection for Firefighters