At their core, work boots are essential PPE because they are engineered to mitigate specific, severe workplace hazards that regular footwear simply cannot address. They serve as the first line of defense against a range of dangers, from crushing impacts and sharp object punctures to electrical shocks and chemical burns, all while providing the necessary support for long hours of demanding physical work.

The critical function of a work boot isn't just to cover the foot, but to act as a highly specialized shield. Its value comes from engineering that directly counters the precise dangers of a specific environment, from falling objects to hazardous materials.

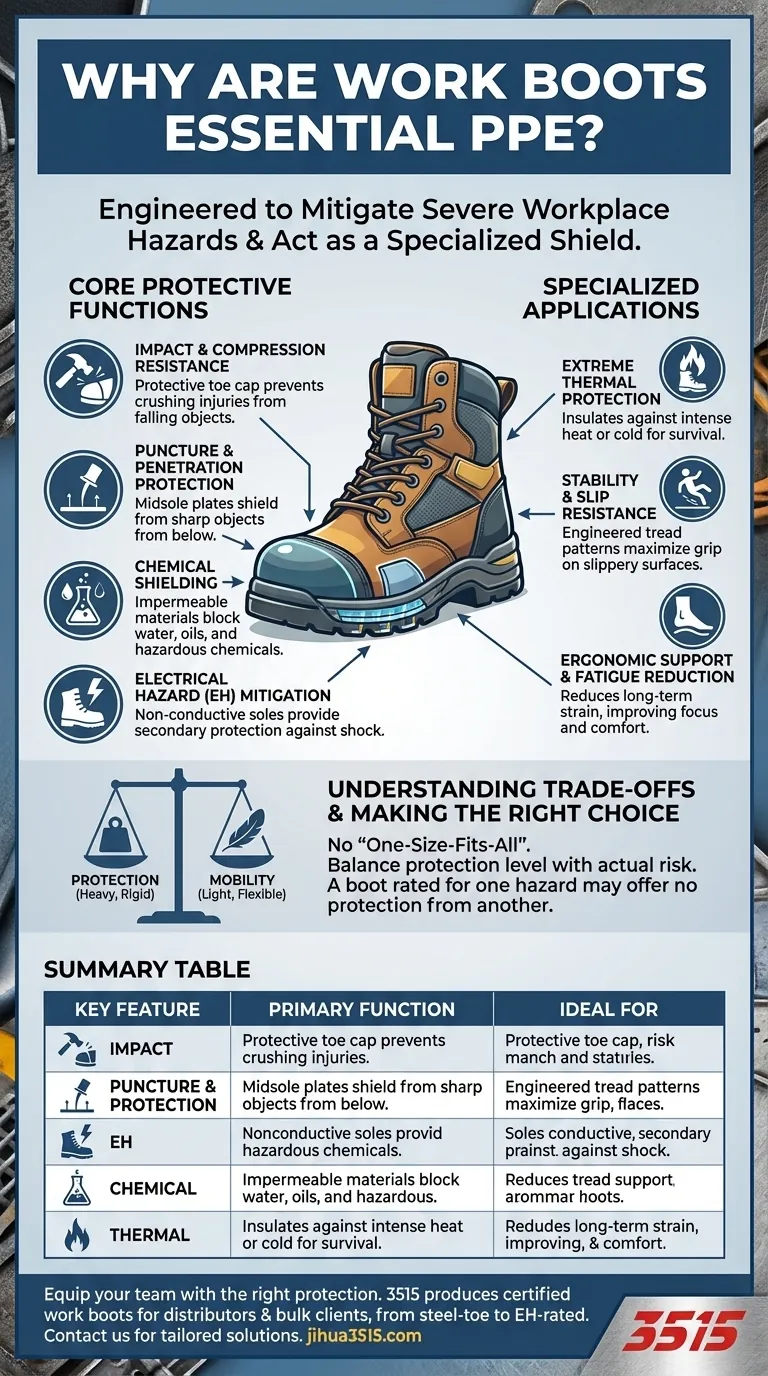

The Core Protective Functions of Work Boots

To understand why work boots are indispensable, we must look beyond the general idea of "safety" and examine their specific, engineered functions. Each feature is a direct response to a known workplace risk.

Impact and Compression Resistance

The most recognized feature of a safety boot is its protective toe cap. These are designed to prevent crushing injuries to the toes from falling objects or compression from heavy machinery. This is a non-negotiable feature in environments like construction, manufacturing, and logistics.

Puncture and Penetration Protection

Many job sites are littered with sharp objects like nails, screws, and scrap metal. Work boots can be equipped with puncture-resistant plates in the midsole, which protect the sole of the foot from being pierced from below.

Environmental and Chemical Shielding

Standard shoes offer minimal protection against liquids. Work boots are often constructed from materials like rubber, PVC, or specialized chemical-resistant polymers to create an impermeable barrier against water, mud, oils, and hazardous chemicals, keeping feet dry and safe from exposure.

Electrical Hazard Mitigation

For electricians and others working near live circuits, specialized work boots are critical. Electrical Hazard (EH) rated boots are made with non-conductive soles and heels, providing a secondary source of protection against accidental electrocution.

Beyond Basic Safety: Specialized Applications

The essential nature of work boots is most clear in highly specialized fields where the footwear is designed to counter extreme and unique environmental threats.

Extreme Thermal Protection

In environments with extreme temperatures, the right boot is a matter of survival. As an example, wildfire boots are essential because they are built to protect feet from the intense ambient heat of a fire line, preventing severe burns and ensuring a firefighter can remain effective and mobile in a hazardous zone.

Stability and Slip Resistance

Slips, trips, and falls are among the most common workplace accidents. Work boot outsoles are engineered with specific materials and tread patterns to maximize grip on slippery, uneven, or oily surfaces, significantly reducing this risk.

Ergonomic Support and Fatigue Reduction

A boot's protective value also lies in its ability to prevent long-term strain. Proper ankle support, cushioning, and an ergonomic design reduce fatigue over long shifts. This not only improves comfort but also enhances a worker's focus and lowers the risk of accidents caused by exhaustion.

Understanding the Trade-offs

Choosing the right work boot involves understanding that no single boot is perfect for every task. The design of protective footwear is always a balance of competing needs.

Protection vs. Mobility

Heavier protection, such as thick metatarsal guards that protect the top of the foot, will inevitably add weight and reduce flexibility. The key is to match the level of protection to the actual risk level of the job without unnecessarily hindering movement.

Material Limitations

A boot designed for maximum chemical resistance might not offer the best breathability or heat protection. Similarly, a lightweight, flexible boot may not provide the same level of impact resistance as a heavy-duty steel-toed model.

The Myth of a "One-Size-Fits-All" Solution

Using the wrong type of work boot can create a false sense of security. A boot rated for slip resistance on a wet floor provides no protection from a falling I-beam. It is crucial to assess the specific hazards of your environment and select a boot with certifications that match.

Making the Right Choice for Your Environment

Your choice of work boot should be a direct reflection of the risks you face daily.

- If your primary risk is falling objects or heavy equipment: Prioritize boots with certified safety toes (steel or composite) and consider metatarsal guards for maximum protection.

- If you work around sharp ground debris like on construction sites: Ensure your boots have a certified puncture-resistant sole plate to protect against penetration.

- If your environment involves liquids, chemicals, or wet conditions: Select boots made from appropriate waterproof or chemical-resistant materials like rubber, PVC, or specially treated leather.

- If you face extreme temperatures or electrical hazards: You must use boots specifically rated for heat insulation, cold protection, or Electrical Hazard (EH) standards.

Ultimately, selecting the correct work boot is a foundational act of professional risk management.

Summary Table:

| Key Protective Feature | Primary Function | Ideal For |

|---|---|---|

| Impact & Compression Resistance | Prevents toe injuries from falling objects | Construction, Manufacturing, Logistics |

| Puncture Protection | Shields soles from nails, glass, and sharp debris | Construction, Demolition, Waste Management |

| Electrical Hazard (EH) Rating | Provides secondary protection against electrocution | Electricians, Utility Workers |

| Chemical & Environmental Shielding | Blocks water, oils, and hazardous chemicals | Chemical Plants, Agriculture, Food Processing |

| Extreme Thermal Protection | Insulates against intense heat or cold | Firefighting, Foundries, Cold Storage |

Ensure your team is equipped with the right protection for their specific hazards. As a large-scale manufacturer, 3515 produces a comprehensive range of certified work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, from steel-toe boots for construction to EH-rated and chemical-resistant models. We help you mitigate risk, enhance productivity, and meet compliance standards with durable, purpose-built footwear. Contact 3515 today for a tailored solution that matches your exact workplace demands.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the protective functions of industrial safety boots in sugar factory clarification stations? Thermal & Slip Experts

- What primary protective functions do industrial safety shoes provide? Maximize Safety in Heavy Machinery Maintenance

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What protective features do professional Safety Shoes provide in shipyard environments? Maximize Worker Safety

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear