Okay, here's what I'm thinking. The user wants to know why these shoes are important, not just that they are. My role is to be a technical advisor, so I need to go deeper than just restating obvious facts. I need to explain the science and the practical application.

Here's the core idea:

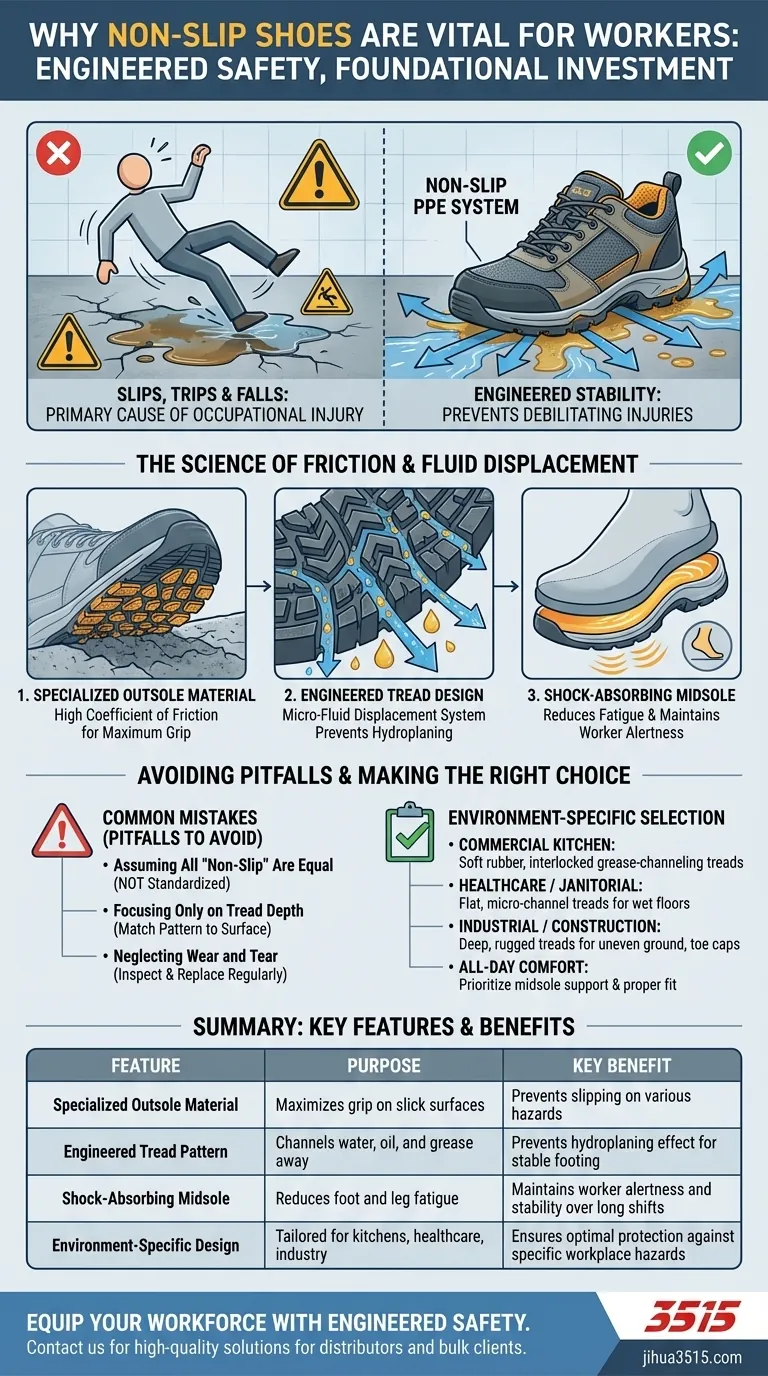

The effectiveness of a non-slip shoe isn't just about a "grippy" material; it's a carefully engineered system of sole material, tread design, and fluid displacement that creates stability where it matters most. Understanding your specific work environment is the key to selecting the right system.

First, I need to address the basic question. Slips, trips, and falls are a huge problem in workplaces. They lead to all sorts of injuries, from sprains and fractures to more serious issues. Non-slip shoes directly address this by creating traction, giving you balance on slick surfaces, and making it harder to lose your footing. That's the what. Now, let's talk about how.

The real magic is in the design. We're talking about high-quality rubber (or synthetic rubber) outsoles. These maximize the friction between the shoe and the floor. But the tread pattern is critical. Deep grooves help on uneven surfaces, but intricate patterns that channel liquids (like water or oil) away from the shoe are even more important on smooth surfaces. It's like car tires; we need to get rid of the liquid between the shoe and the surface for maximum grip. And it's not just the outsole; thick soles and shock-absorbing midsoles reduce fatigue and keep you stable and alert.

So, what makes a truly effective non-slip shoe? The outsole is key, of course, with its specific patterns and materials. But the midsole and insole are also crucial for comfort and shock absorption. The upper material needs to be water-resistant to keep your feet dry, which improves comfort and health.

It's tempting to think "more tread = better," but that's not always the case. Not all non-slip shoes are created equal! A shoe designed for a hospital might be useless in a greasy kitchen. You need to think about your specific work environment. Also, a shoe with a deep tread might be good for construction, but intricate channels are better for wet environments. And remember: fit is absolutely vital. A poorly fitting shoe won't be safe, no matter how "non-slip" it claims to be. Finally, don't forget that treads wear down over time! Regular inspections and replacements are a must.

Here's how to make the right choice:

- For a commercial kitchen: Look for shoes with soft rubber outsoles and interlocked tread patterns that channel away grease and oil.

- For healthcare or similar environments: Look for shoes with a flatter, micro-channel tread pattern.

- For industrial or construction sites: You need deep, rugged treads for uneven surfaces, often with reinforced toe caps.

- For general all-day comfort and safety: Prioritize excellent midsole support and a proper fit to reduce fatigue.

Basically, picking the right non-slip footwear is an informed engineering decision that is a foundational investment in your personal safety. At its core, the vitality of non-slip shoes is a matter of fundamental physics and workplace safety. They are essential because they are specifically engineered to counteract the primary cause of occupational injuries across numerous industries: slips, trips, and falls. By providing reliable traction on hazardous surfaces like wet, oily, or greasy floors, these shoes prevent debilitating injuries ranging from sprains and fractures to more severe long-term damage.

A non-slip shoe is not just footwear; it is a critical piece of personal protective equipment. Its effectiveness lies in a purpose-built system of outsole material and tread design engineered to increase friction and actively channel fluids away from the point of contact, ensuring stability where it is most needed.

How Non-Slip Technology Actually Works

To truly understand their importance, you must look past the simple label of "non-slip" and appreciate the engineering principles that provide the protection.

The Science of Friction

The foundation of a non-slip shoe is its outsole material, which is typically made from a soft rubber or a specialized synthetic compound. This material is chosen for its high coefficient of friction, which is its inherent ability to grip a surface and resist sliding.

The Critical Function of Tread Design

The pattern on the bottom of the shoe is arguably its most important feature. Unlike a standard shoe, the tread pattern is not for aesthetics; it's a micro-fluid displacement system.

Intricate, circular, or interlocked patterns create channels that push liquids like water and oil outward from under the sole. This prevents a layer of fluid from forming between the shoe and the floor, a phenomenon similar to hydroplaning in a car tire, thus maximizing direct contact and grip.

Beyond the Outsole: The Importance of Support

True stability comes from more than just the outsole. High-quality non-slip shoes incorporate thick, shock-absorbing midsoles.

This feature reduces fatigue in the feet, legs, and back during long shifts. Reduced fatigue is a critical safety factor, as tired workers are more prone to missteps and accidents.

Common Pitfalls to Avoid

Simply purchasing a shoe labeled "non-slip" is not enough. Several common misunderstandings can compromise a worker's safety.

Mistake 1: Assuming All "Non-Slip" Shoes Are Equal

The term "slip-resistant" is not universally standardized. A shoe designed for the lightly wet floors of a hospital will likely fail in the greasy environment of a commercial kitchen.

The effectiveness of a shoe is entirely dependent on the specific hazards of its intended environment.

Mistake 2: Focusing Only on Tread Depth

Deep, rugged treads are excellent for uneven terrain or surfaces with solid debris. However, on flat, wet, or oily surfaces, an intricate, fluid-channeling pattern is far more effective.

The goal is to match the tread design to the surface type, not to simply choose the deepest lugs.

Mistake 3: Neglecting Wear and Tear

The safety features of a non-slip shoe degrade over time. As the soft rubber outsole wears down, the sharp edges of the tread pattern become rounded and less effective at channeling away liquid.

Shoes must be inspected regularly and replaced when the tread pattern is visibly worn.

Making the Right Choice for Your Environment

Your selection process should be a deliberate assessment of your specific workplace hazards and physical needs.

- If your primary focus is a commercial kitchen or food service area: Prioritize shoes with soft rubber outsoles and intricate, interlocked tread patterns designed to channel away grease and oil.

- If your primary focus is a healthcare or janitorial environment: Look for shoes with micro-channel tread patterns that maximize surface area contact on smooth, wet floors.

- If your primary focus is an industrial or construction site: You need shoes with deep, rugged treads for traction on uneven ground, often combined with safety features like reinforced toe caps.

- If your primary focus is reducing fatigue during long shifts: Ensure the shoe has excellent midsole support and a proper fit, as comfort is a direct contributor to maintaining balance and awareness.

Ultimately, choosing the right non-slip footwear is an informed engineering decision and a foundational investment in your personal safety.

Summary Table:

| Feature | Purpose | Key Benefit |

|---|---|---|

| Specialized Outsole Material | High-friction rubber/synthetic compound | Maximizes grip on slick surfaces |

| Engineered Tread Pattern | Channels water, oil, and grease away | Prevents hydroplaning effect for stable footing |

| Shock-Absorbing Midsole | Reduces foot and leg fatigue | Maintains worker alertness and stability over long shifts |

| Environment-Specific Design | Tailored for kitchens, healthcare, industry | Ensures optimal protection against specific workplace hazards |

Equip Your Workforce with Engineered Safety

As a leading manufacturer, 3515 produces a comprehensive range of non-slip footwear designed for the specific demands of your industry. Our expertise in engineering outsoles with advanced tread patterns and durable materials ensures maximum protection for your team.

We provide high-quality, reliable non-slip shoes and boots for distributors, brand owners, and bulk clients across all sectors. Our production capabilities encompass all types of safety footwear, from kitchen clogs to industrial boots.

Let's enhance your workplace safety protocol together. Contact our team today to discuss your requirements and receive a customized solution.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What is the benefit of deeper grooves in slip-resistant shoe soles? Maximize Traction & Safety

- What are the top benefits of wearing non-slip shoes? Ensure Safety and Comfort for Demanding Work

- What is the benefit of angled or rounded sole designs in non-slip shoes? Prevent Hydroplaning for Superior Grip

- How does outsole thickness contribute to slip resistance? The Truth About Material & Tread Design

- What are some methods to make regular shoes more slip-resistant? Ensure Safety with Proven Solutions

- What is the significance of tread patterns in non-slip shoes? Prevent Slips with Expert Sole Design

- Why is a lightweight design important for chef shoes? Boost Endurance and Agility in the Kitchen

- Why is footwear important for dental professionals? Prevent Pain and Boost Your Career Longevity