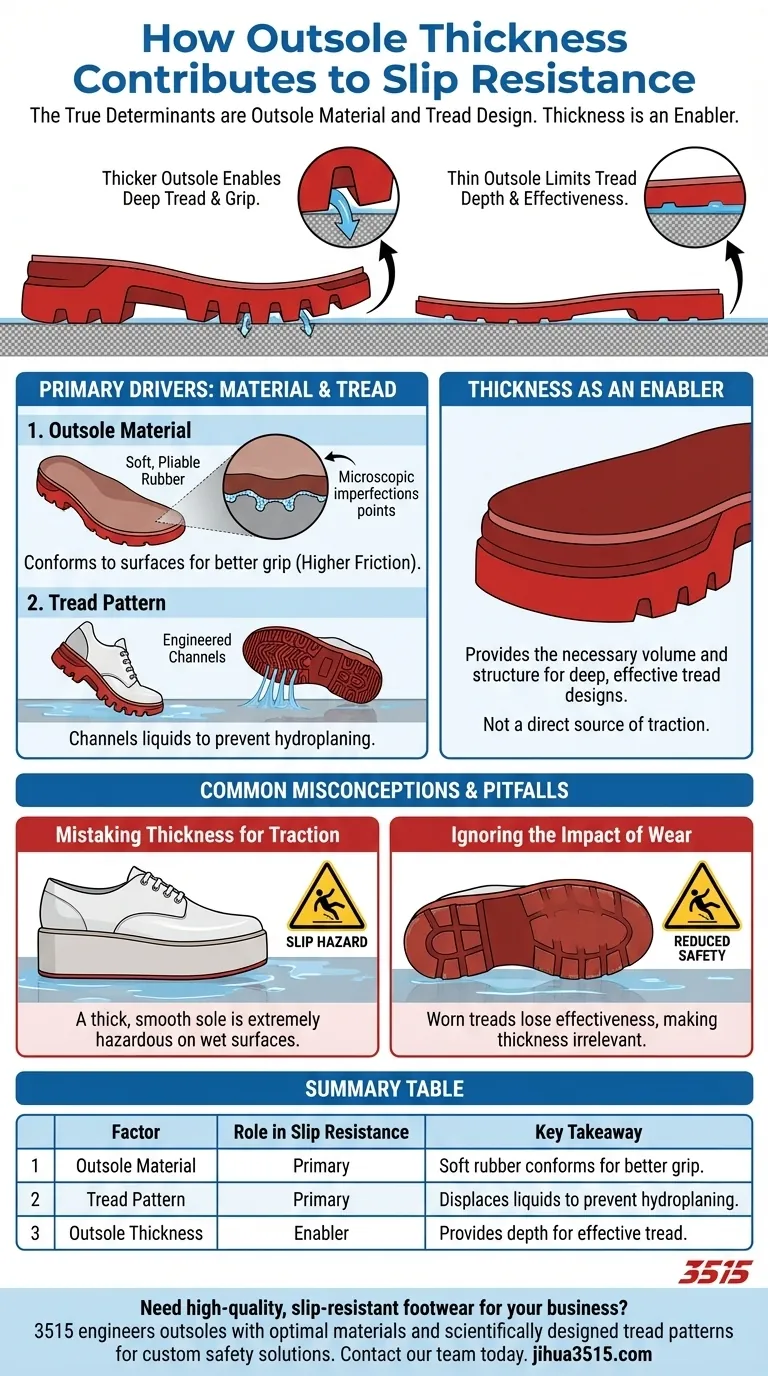

At its core, outsole thickness is often correlated with slip resistance, but it is not the direct cause. A thicker outsole enables the design of deeper, more effective tread patterns that are essential for channeling away liquids and maintaining grip.

The true determinants of a shoe's slip resistance are its outsole material and tread design. Thickness is a secondary characteristic that supports these primary features, rather than providing traction on its own.

Beyond Thickness: The Real Drivers of Slip Resistance

Many assume that a thicker slab of rubber between you and the ground automatically means better grip. The reality is far more nuanced. True slip resistance is an engineered outcome based on principles of friction and fluid dynamics.

The Critical Role of Outsole Material

The compound used to create the outsole is the first point of contact with a surface. A softer, more pliable material, such as high-quality rubber, can better conform to microscopic imperfections in the ground.

This conformity maximizes the surface area in contact with the floor, which in turn increases the coefficient of friction and provides a stronger grip. A hard, rigid material will simply skate over the top.

The Engineering of Tread Patterns

The most common cause of slipping is a thin layer of liquid—like water or oil—that prevents the shoe from making direct contact with the walking surface. This phenomenon is known as hydroplaning.

An effective tread pattern features a network of deep channels and grooves. These channels give liquids an escape route, forcing them out from under the shoe so the solid parts of the outsole can make firm contact with the ground.

How Thickness Fits into the Equation

This is where thickness becomes relevant. A thicker outsole is a prerequisite for creating deep, aggressive tread patterns. You simply cannot carve effective channels into a very thin sole.

Therefore, while thickness itself doesn't provide grip, it is an essential enabler for the tread designs that do. It provides the necessary volume and structural integrity for these safety features to be effective.

Common Misconceptions and Pitfalls

Focusing solely on outsole thickness can lead to poor footwear choices and a false sense of security. Understanding the common pitfalls is crucial for making an informed decision.

Mistaking Thickness for Traction

A shoe can have a very thick outsole but offer terrible slip resistance. Imagine a platform shoe with a thick but completely smooth, hard plastic bottom. On a wet surface, it would be extremely hazardous.

This design lacks both the proper material to create friction and the tread pattern to prevent hydroplaning. This proves that thickness alone is not a reliable indicator of safety.

Ignoring the Impact of Wear

Even a well-designed shoe with a thick sole will lose its effectiveness as the treads wear down. Once the channels become shallow, they can no longer displace liquid efficiently.

At this point, the shoe's remaining thickness is irrelevant. The functional part of its safety design has been compromised, and its slip resistance will be significantly reduced.

Making the Right Choice for Your Goal

To select the right shoe, shift your focus from thickness to the features it enables. Analyze the outsole material and tread design in the context of your specific environment.

- If your primary focus is safety on wet surfaces (e.g., kitchens, hospitals): Look for soft rubber outsoles with many small, intricate channels designed to disperse water quickly.

- If your primary focus is stability on uneven terrain (e.g., hiking): Prioritize shoes with a thick, firm outsole that supports deep, widely-spaced lugs for gripping loose dirt and rock.

- If your primary focus is avoiding hydroplaning in industrial settings: Seek shoes with certified slip-resistant ratings and tread patterns specifically designed to channel away oil or chemicals.

By evaluating the material and tread design first, you can make an informed choice that truly prioritizes your safety.

Summary Table:

| Factor | Role in Slip Resistance | Key Takeaway |

|---|---|---|

| Outsole Material | Primary | Soft, pliable rubber conforms to surfaces for better grip. |

| Tread Pattern | Primary | Channels and grooves displace liquids to prevent hydroplaning. |

| Outsole Thickness | Enabler | Provides the depth needed for effective tread patterns. |

Need high-quality, slip-resistant footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety and occupational footwear for distributors, brand owners, and bulk clients. Our expertise lies in engineering outsoles with the optimal combination of advanced materials and scientifically designed tread patterns to meet specific safety standards and environmental demands.

Let us help you equip your workforce with reliable, high-performance footwear. Contact our team today to discuss your custom manufacturing needs.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What types of workplace hazards require protective footwear? Essential Guide for Workplace Safety

- What materials are used in the construction of these boots? A Guide to Velour Leather, Textile & PU Soles

- How is puncture resistance evaluated in footwear soles? Balance Protection, Comfort & Safety

- What should warehouse work shoes include for safety? Essential Features for All-Day Protection

- What does a green triangle symbol on safety footwear mean? Your Guide to Maximum Puncture & Impact Protection