The design of a shoe's sole edge is a critical, often overlooked, element of slip resistance. Angled or rounded sole designs are not an aesthetic choice; they are an engineering solution designed specifically to channel liquids out from underneath the shoe. This prevents a layer of fluid from getting trapped, which would cause the shoe to hydroplane and lose all traction with the floor.

The core benefit of an angled or rounded sole is liquid displacement. While the tread pattern provides grip, the shape of the edge acts like a squeegee, actively pushing water, oil, and other fluids away to maintain direct, secure contact between the sole and the walking surface.

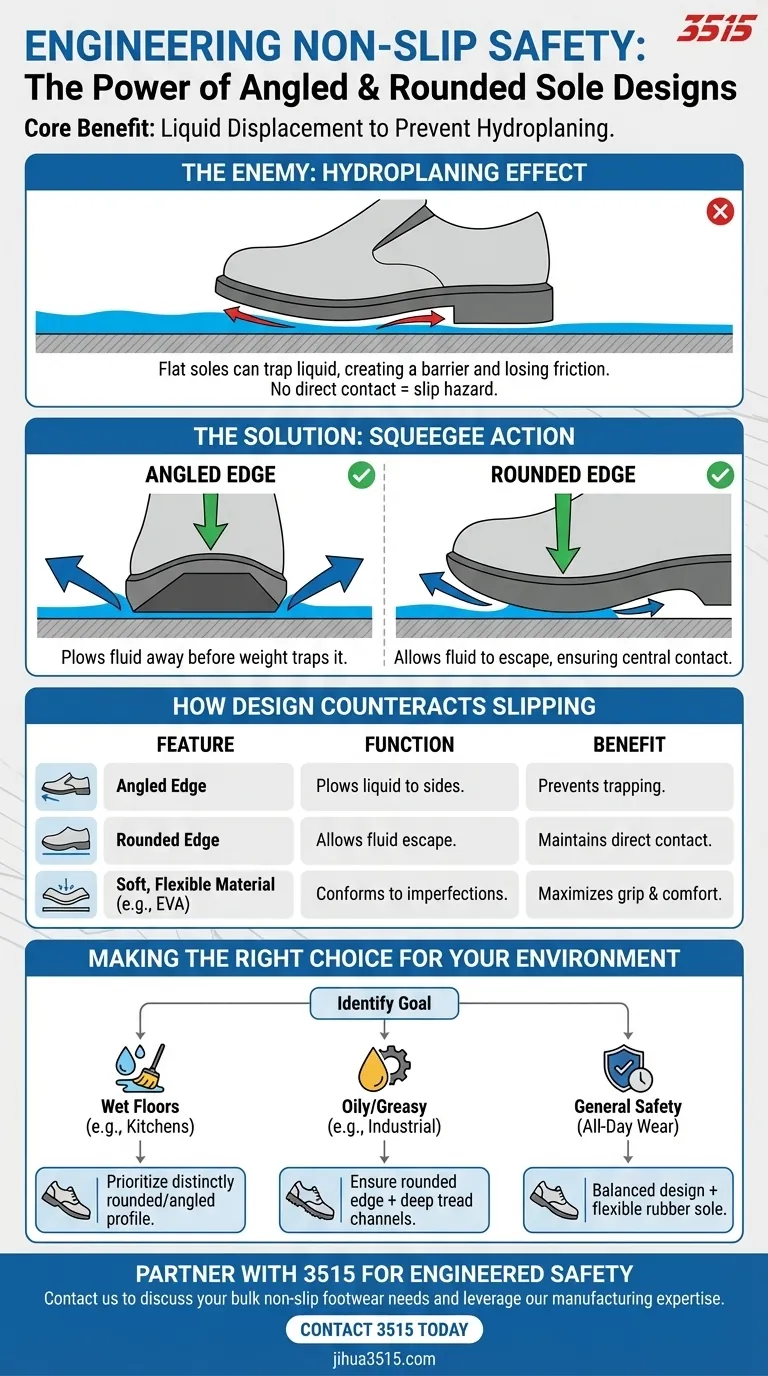

The Physics of a Slip: Why Liquid is the Enemy

To understand the solution, we must first understand the problem. A slip doesn't happen because a floor is wet; it happens because the liquid creates a barrier between your shoe and the floor, eliminating the friction you rely on to walk safely.

The Hydroplaning Effect

When you step on a wet or greasy surface with a flat-edged shoe, your body weight can trap a thin film of liquid underneath the sole. This creates a situation identical to a car tire hydroplaning on a wet road. The shoe is literally floating on the liquid, with no direct contact with the solid ground beneath.

Losing Surface Contact

Friction is a direct result of two surfaces making contact. Once a liquid barrier is in place, the friction drops to almost zero, regardless of how deep or intricate your shoe's tread pattern is. The primary goal of a non-slip shoe is to prevent this barrier from ever forming.

How Sole Design Counteracts Slipping

Angled and rounded sole edges are a proactive defense against hydroplaning. They work in concert with the tread pattern and sole material to keep you grounded.

The Squeegee Action of Angled Edges

As your foot lands, an angled or beveled edge cuts into the liquid on the floor. It effectively plows the fluid out to the sides before the full weight of your step can trap it under the main contact patch of the sole.

How a Rounded Profile Prevents Trapping

A slightly rounded profile serves a similar purpose. Instead of a hard, 90-degree edge that can seal against the floor and trap liquid, the curve allows fluid to escape easily from the sides as pressure is applied. This ensures the central part of the sole can make solid contact.

The Role of Soft, Flexible Materials

This design feature is most effective when paired with a relatively soft and flexible outsole, such as one made from EVA rubber. A softer material can better conform to microscopic imperfections in the floor, further helping to push liquid away and maximize the contact area for superior grip.

Understanding the Trade-offs

While highly effective, this design feature is not a silver bullet. Understanding its limitations is key to making an informed choice for your specific environment.

It Complements, Not Replaces, Tread

A rounded edge helps clear liquid, but the tread pattern is what provides the final grip. A shoe with a great rounded edge but a completely worn-out, smooth tread is still a major slip hazard. The two systems must work together.

Effectiveness Varies by Liquid

This design is exceptionally effective against thin liquids like water, soap, and light oils. For very thick and viscous fluids, such as heavy grease or gels, the depth and design of the tread channels become even more critical for providing an escape route for the contaminant.

Making the Right Choice for Your Goal

When selecting footwear, look at the sole edge in combination with the tread and material to match your specific work environment.

- If your primary focus is on wet floors (e.g., kitchens, cleaning crews): Prioritize a shoe with a distinctly rounded or angled sole profile to maximize water displacement.

- If your primary focus is on oily or greasy surfaces (e.g., automotive shops, industrial settings): Ensure the rounded edge is paired with a deep, wide-channeled tread pattern designed to handle thicker liquids.

- If your primary focus is all-day wear and general safety: Look for a balanced design that combines the rounded edge feature with a flexible, shock-absorbing rubber sole.

Ultimately, choosing the right shoe comes down to understanding that safety is engineered, not accidental.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| Angled Edge | Acts like a squeegee, plowing liquids out to the sides. | Prevents liquid from being trapped under the sole. |

| Rounded Edge | Allows fluid to escape easily from the sides as pressure is applied. | Maintains direct contact between the sole and the floor. |

| Soft, Flexible Material (e.g., EVA Rubber) | Conforms to floor imperfections to push liquid away. | Maximizes the contact area for superior grip and comfort. |

Engineer Safety into Every Step with 3515

As a large-scale manufacturer, 3515 produces a comprehensive range of non-slip footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with features like angled and rounded soles to meet the specific demands of your work environment.

We can help you provide your team or customers with footwear that combines advanced liquid displacement technology with durable, comfortable materials for all-day protection.

Contact 3515 today to discuss your non-slip footwear needs and discover how our manufacturing expertise can become your competitive advantage.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- What types of workplace hazards require protective footwear? Essential Guide for Workplace Safety

- What does a green triangle symbol on safety footwear mean? Your Guide to Maximum Puncture & Impact Protection

- What are the EN ISO 20345 norms for safety shoes? A Guide to Choosing the Right Protection

- Why is slip resistance important in safety footwear? Prevent Costly Workplace Slips and Falls

- What materials are used in the construction of these boots? A Guide to Velour Leather, Textile & PU Soles