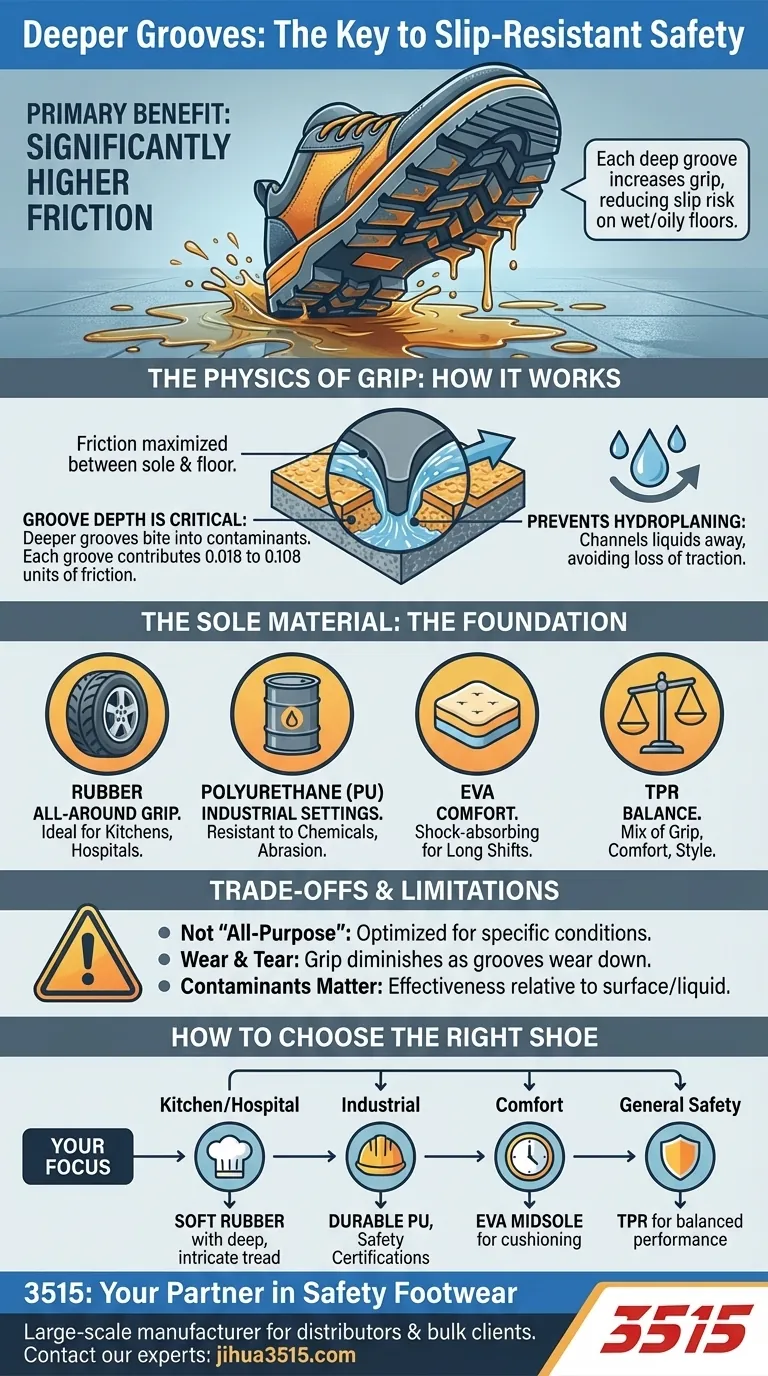

The primary benefit of deeper grooves in a slip-resistant shoe is to create significantly higher friction against the floor surface. Each deep groove contributes to the shoe's ability to grip, effectively reducing the chance of slipping on hazardous surfaces like wet or oily floors.

While deeper grooves are a critical feature for increasing friction, they are just one component of a comprehensive safety system. True slip resistance is achieved through the specific combination of groove depth, tread pattern, and the composition of the sole material itself.

The Physics of Grip: How Slip Resistance Works

To understand why deeper grooves are effective, we must first understand the fundamental principle they exploit: friction.

The Core Role of Friction

Friction is the resistance that occurs when two surfaces rub against each other. Slip-resistant shoes are engineered to maximize this force between the sole and the floor.

The sole's material texture, groove depth, and tread pattern all work together to create a higher coefficient of friction, which translates directly into a better grip.

Why Groove Depth Is Critical

Deeper grooves provide a more aggressive tread that can better bite into the floor surface, especially when contaminants like water or oil are present.

According to technical analysis, each groove can contribute between 0.018 to 0.108 units of friction, depending on the specific floor conditions. More grooves, and deeper grooves, amplify this effect.

It's Not Just Depth, It's Pattern

The arrangement of the grooves is as important as their depth. An effective tread pattern helps to channel liquids out from under the shoe.

This prevents a dangerous situation called hydroplaning, where a thin layer of liquid separates the sole from the floor, causing a near-total loss of traction.

The Foundation of Safety: The Sole Material

The material that the grooves are cut into is the foundation of the shoe's performance. The best tread design in the world will fail if it's made from an inappropriate material.

Rubber for All-Around Grip

Soft rubber is a common choice for its durability and flexibility. It offers excellent grip, making it ideal for high-risk environments like commercial kitchens and hospitals where wet floors are common.

Polyurethane (PU) for Industrial Settings

PU soles are lightweight yet highly resistant to chemicals and abrasion. This makes them a superior choice for industrial environments where chemical spills might occur.

Ethylene Vinyl Acetate (EVA) for Comfort

EVA is known for its exceptional shock-absorbing properties. It's often used in shoes designed for workers who spend long hours on their feet, as it reduces fatigue and increases comfort.

Thermoplastic Rubber (TPR) for Balance

TPR is a composite material that blends the properties of rubber and plastic. It offers a good balance of slip resistance, comfort, and style for less demanding environments.

Understanding the Trade-offs and Limitations

No shoe is perfect for every single situation. Understanding the limitations of slip-resistant footwear is crucial for maintaining safety.

The Myth of the "All-Purpose" Sole

A sole designed to perform on oily, greasy floors may not be the optimal choice for loose, dusty surfaces. The tread and material are always optimized for a specific set of conditions.

Wear and Tear Diminishes Grip

As a shoe is worn, the sole material wears down, and the grooves become shallower. This degradation directly reduces the shoe's slip resistance and is a key reason why safety footwear must be replaced regularly.

Contaminants Change Everything

The effectiveness of a slip-resistant shoe is always relative to the surface and the contaminant. A shoe that performs well on a water-covered floor may not provide the same level of safety on an oily one.

How to Choose the Right Slip-Resistant Shoe

Selecting the right shoe requires matching its features to your specific work environment and goals.

- If your primary focus is a kitchen or hospital: Prioritize a soft rubber sole with a deep, intricate tread pattern designed to channel away water.

- If your primary focus is an industrial setting: Look for a durable Polyurethane (PU) sole and verify it has the necessary safety certifications, such as a steel toe.

- If your primary focus is comfort during long shifts: Consider shoes that incorporate an EVA midsole for superior cushioning and shock absorption.

- If your primary focus is general safety in mixed conditions: A Thermoplastic Rubber (TPR) sole can provide a reliable balance of performance, durability, and comfort.

Ultimately, a truly effective safety shoe is one where the groove design, tread pattern, and sole material work together to conquer the specific challenges of your environment.

Summary Table:

| Feature | Key Benefit | Ideal For |

|---|---|---|

| Deeper Grooves | Higher friction; channels liquids away | Wet, oily surfaces (kitchens, hospitals) |

| Soft Rubber Sole | Excellent all-around grip & durability | Commercial kitchens, healthcare |

| Polyurethane (PU) Sole | Chemical & abrasion resistance | Industrial settings with spills |

| EVA Midsole | Superior comfort & shock absorption | Long shifts on hard floors |

Need the right safety shoe for your specific environment?

As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the optimal combination of groove depth, tread pattern, and sole material to protect your workforce.

Contact our experts today to discuss your requirements and get a quote tailored to your needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear