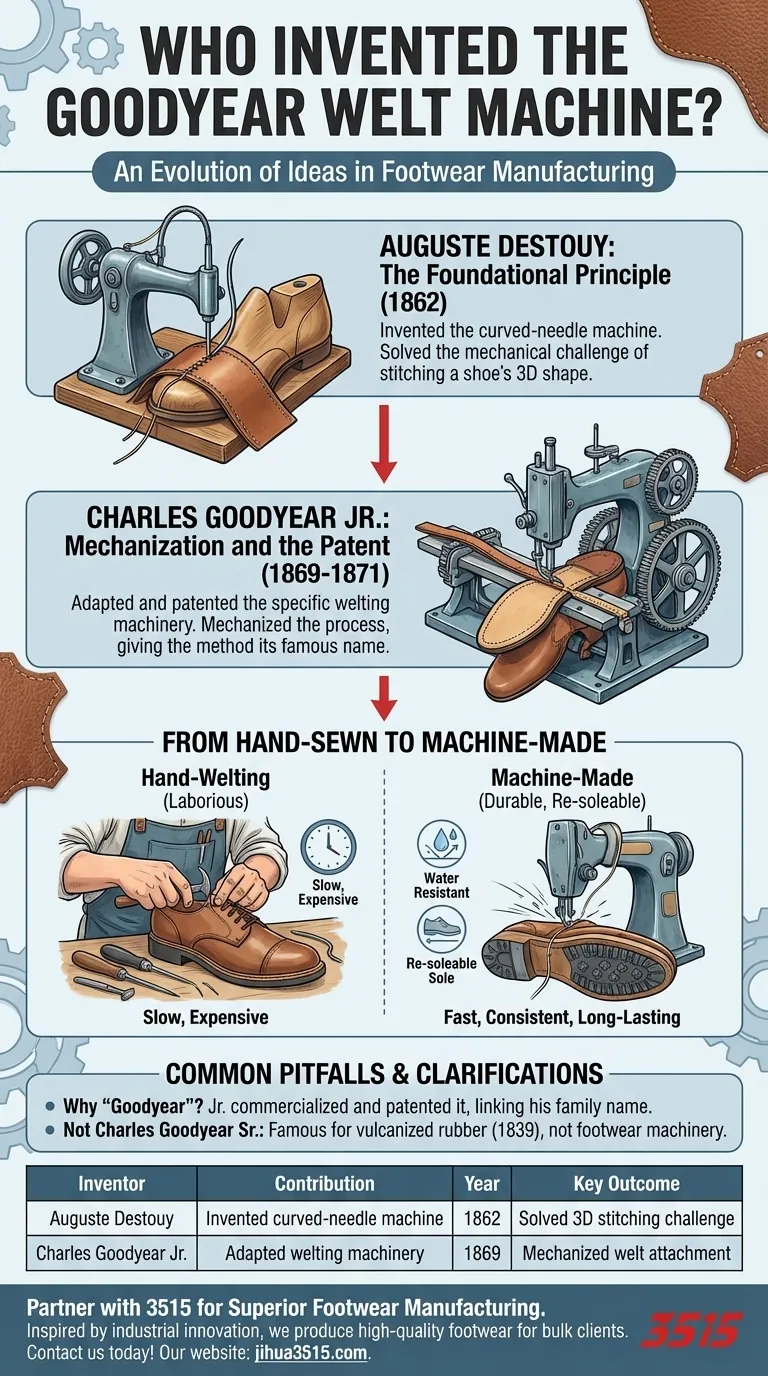

While the process bears his name, the foundational principle behind the Goodyear welt machine was first invented by Auguste Destouy in 1862. It was Charles Goodyear Jr. who later adapted and patented the specific machinery for welting shoes in 1869, mechanizing a traditionally hand-sewn process and giving the method its famous name.

The history of the Goodyear welt is not the story of a single inventor, but an evolution of ideas. Destouy created the core mechanical concept, while Goodyear Jr. engineered the specific application that revolutionized the footwear industry.

The Two Key Innovators: Destouy and Goodyear Jr.

To understand the origin, it's essential to recognize the distinct contributions of two different inventors working several years apart.

Auguste Destouy: The Foundational Principle (1862)

The core breakthrough came from Auguste Destouy. In 1862, he invented a machine that used a curved needle to stitch the soles onto turned shoes.

This machine was the first to solve the mechanical challenge of stitching around the complex, three-dimensional shape of a shoe last, laying the groundwork for what was to come.

Charles Goodyear Jr.: Mechanization and the Patent (1869)

Seven years later, Charles Goodyear Jr.—the son of the famous rubber vulcanization inventor—acquired the patents for Destouy's machine.

He significantly refined and adapted the machinery specifically to automate the process of attaching the welt, a strip of leather that runs along the perimeter of the upper. He patented his improved welt-sewing machine in 1871, and his name became synonymous with the method.

From Hand-Sewn to Machine-Made

The invention's true impact was its ability to replicate the quality of a laborious, handcrafted technique with industrial speed and consistency.

The Problem: The Labor of Hand-Welting

Before this machinery, welting was a highly skilled and time-consuming process performed entirely by hand by master cordwainers. This made high-quality, durable, and repairable footwear expensive and less accessible.

The Solution: A Durable, Mechanical Join

The Goodyear welt machine automated this process. It creates a robust mechanical join by stitching the upper, the lining, and the welt together before attaching the outsole to the welt.

This method creates a strong, water-resistant, and—most importantly—easily re-soleable shoe, dramatically extending its lifespan.

Common Pitfalls and Clarifications

The shared name and overlapping history often lead to confusion. Clarifying these points is key to understanding the full story.

Why Is It Named "Goodyear"?

History often credits the individual who successfully commercializes or popularizes an invention. While Destouy had the initial concept, Goodyear Jr. refined, patented, and brought the specific welting application to the industrial forefront, forever linking his family name to this standard of quality.

Not Charles Goodyear Sr.

A frequent mistake is to credit Charles Goodyear Sr. with the invention. He was a brilliant chemist famous for his 1839 discovery of vulcanized rubber, a pivotal moment for many industries, but he was not involved with the shoemaking machinery developed by his son.

The Legacy of the Invention

Understanding the correct attribution allows for a more accurate appreciation of this landmark in industrial design.

- If your primary focus is the core mechanical concept: The credit belongs to Auguste Destouy for inventing the curved needle machine in 1862.

- If your primary focus is the named construction method: The credit belongs to Charles Goodyear Jr. for adapting and patenting the machinery that mechanized the welting process in 1869.

Ultimately, technological progress is rarely a single event but a chain of improvements built upon foundational ideas.

Summary Table:

| Inventor | Contribution | Year | Key Outcome |

|---|---|---|---|

| Auguste Destouy | Invented the foundational curved-needle machine | 1862 | Solved the mechanical challenge of stitching a shoe's 3D shape |

| Charles Goodyear Jr. | Adapted and patented the specific welting machinery | 1869 | Mechanized the welt attachment, making the method famous |

Partner with 3515 for Superior Footwear Manufacturing

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, high-quality footwear for distributors, brand owners, and bulk clients. Our advanced production capabilities, inspired by the legacy of industrial innovation, ensure every pair meets the highest standards of craftsmanship and durability.

Let's discuss how we can bring your footwear vision to life with efficiency and scale. Contact our team today to start your project.

Visual Guide

Related Products

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

People Also Ask

- How can you identify high-quality boots? A Guide to Durable Materials and Construction

- What is the complete process for deep cleaning leather work boots? A Step-by-Step Guide to Preserve Your Investment

- Why might it be beneficial to pre-heat the boots before applying wax? Achieve Deeper, Longer-Lasting Protection

- What are the best practices for storing leather work boots? Preserve Your Investment for Years

- What are the basic steps to clean leather work boots? A 4-Step Guide to Preserve Your Investment