Occupations that prioritize mobility, electrical safety, and all-day comfort are the most common adopters of composite toe boots. These roles include electricians, engineers, architects, and project managers who require certified protection but need to avoid the weight and electrical conductivity of traditional steel caps.

The choice between composite and steel toe boots is not about which is "better," but which is right for the specific hazards and demands of your job. Composite toes excel in environments where weight, electrical risks, and temperature are the primary concerns, not the constant threat of extreme impact from heavy machinery.

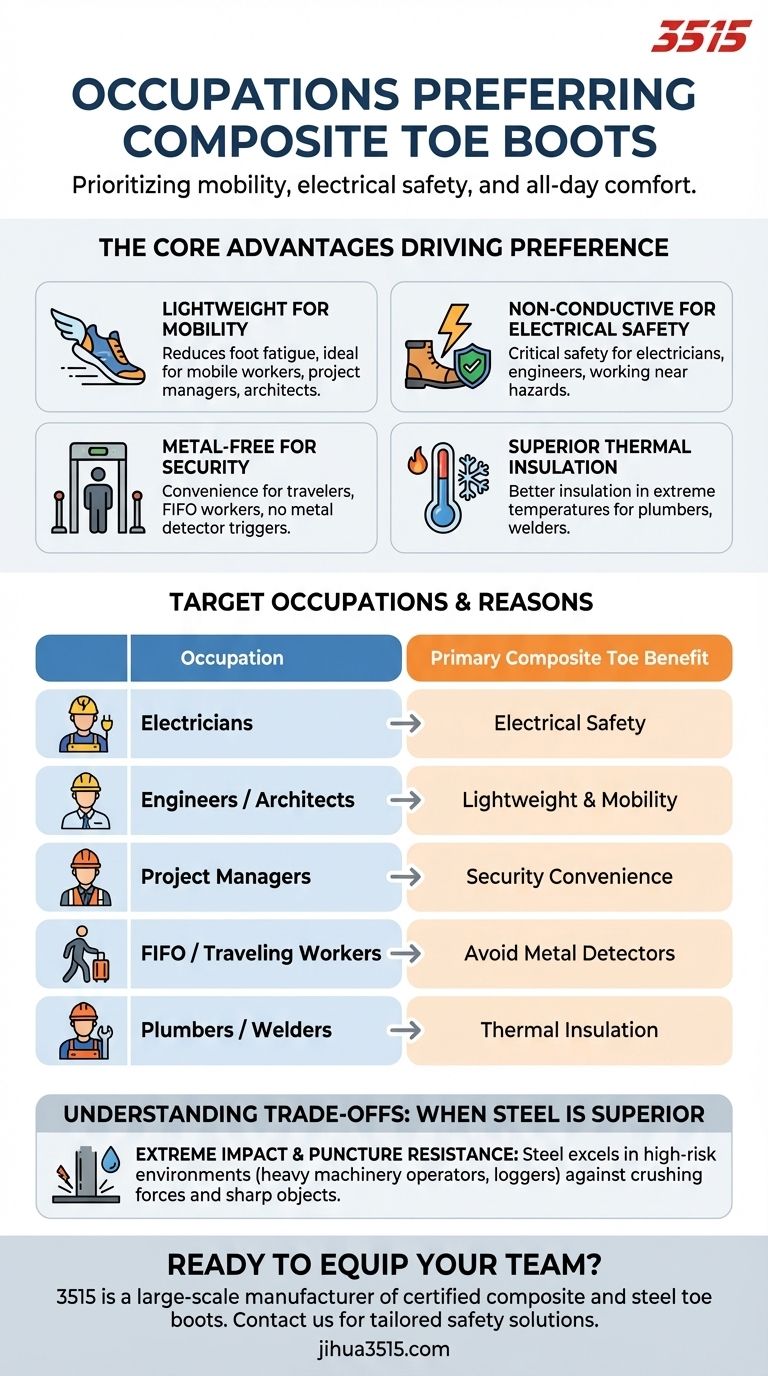

The Core Advantages Driving Composite Toe Preference

The decision to choose composite materials like fiberglass, carbon fiber, or Kevlar stems from a specific set of operational needs. These materials provide distinct advantages over steel in certain work environments.

Lightweight for Mobility and Reduced Fatigue

Composite toe caps are significantly lighter than steel. This reduction in weight minimizes foot fatigue over long shifts.

This makes them ideal for mobile workers, project managers, and architects who spend hours walking across job sites but are not directly operating heavy machinery.

Non-Conductive for Electrical Safety

The primary benefit for certain trades is that composite materials do not conduct electricity. This is a critical safety feature.

Electricians, engineers, and any professional working near potential electrical hazards gain an essential layer of protection by wearing non-metallic boots.

Metal-Free for Security and Convenience

Because they contain no metal, composite toe boots will not set off metal detectors.

This is a major convenience for frequent travelers, FIFO (Fly-In, Fly-Out) workers, or anyone who regularly passes through security checkpoints.

Superior Thermal Insulation

Composite materials are poor conductors of heat and cold. This means they offer better insulation in extreme temperature environments.

Workers exposed to very hot or cold conditions, such as some plumbers or welders, will find composite toe boots far more comfortable than steel toes, which can transfer ambient temperatures directly to the foot.

Understanding the Trade-offs: When Steel Is Superior

While composite toe boots meet the same ASTM safety standards for impact and compression as steel, there are scenarios where steel remains the superior choice. Trust and safety depend on understanding these limitations.

Extreme Impact and Puncture Resistance

Steel can often withstand a single, higher-impact force before being compromised. It is also inherently more resistant to being cut or punctured by sharp, heavy objects.

While a composite toe provides certified protection, it may crack under an extreme force that a steel toe would only dent.

Occupations Requiring Maximum Protection

For roles with a constant, high risk of crushing or falling objects, steel is the traditional and often preferred option.

Occupations like loggers, heavy machinery operators, construction laborers, and disaster relief workers benefit from the uncompromising strength of steel due to the nature of their daily hazards.

Making the Right Choice for Your Role

Your daily tasks and work environment should be the ultimate guide in your decision.

- If your primary focus is electrical safety and avoiding metal detectors: Composite toe boots are the definitive choice.

- If your primary focus is all-day comfort and reduced fatigue while walking: The lightweight nature of composite toes will serve you best.

- If your primary focus is maximum protection from heavy falling objects or crushing forces: You should choose traditional steel toe boots for their superior impact resistance.

Selecting the right protective footwear is a critical decision based on a clear-eyed assessment of your specific job hazards.

Summary Table:

| Occupation | Primary Reason for Composite Toe Preference |

|---|---|

| Electricians | Non-conductive for electrical safety |

| Engineers / Architects | Lightweight for mobility and reduced fatigue |

| Project Managers | Metal-free for convenience at security checkpoints |

| FIFO / Traveling Workers | Avoids setting off metal detectors |

| Plumbers / Welders | Superior thermal insulation in extreme temperatures |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified composite toe and steel toe boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the perfect balance of safety, comfort, and durability tailored to your specific occupational hazards.

Contact 3515 today for a consultation and discover how we can support your safety and procurement needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What role do industrial safety shoes and boots play in fire rescue? Pandemic Intervention & PPE Integration Guide

- What are the key parts of a boot's anatomy? A Guide to Superior Support and Durability

- What problems can occur with frozen boots in winter cycling? Avoid Painful Blisters and Cold Feet

- What are the requirements for wildland firefighter boots? Ensure NFPA 1977 Compliance for Ultimate Safety

- What are the common workplace hazards that can be mitigated with the right work boots? Protect Your Workforce

- What is Gristle Rubber primarily used for? Unbeatable Durability for Industrial Footwear

- How do wildfire boots protect feet from extreme heat? A Multi-Layer Defense System Explained

- In what work situations might cowboy boots not be appropriate? A Guide to Safety & Dress Code Compliance