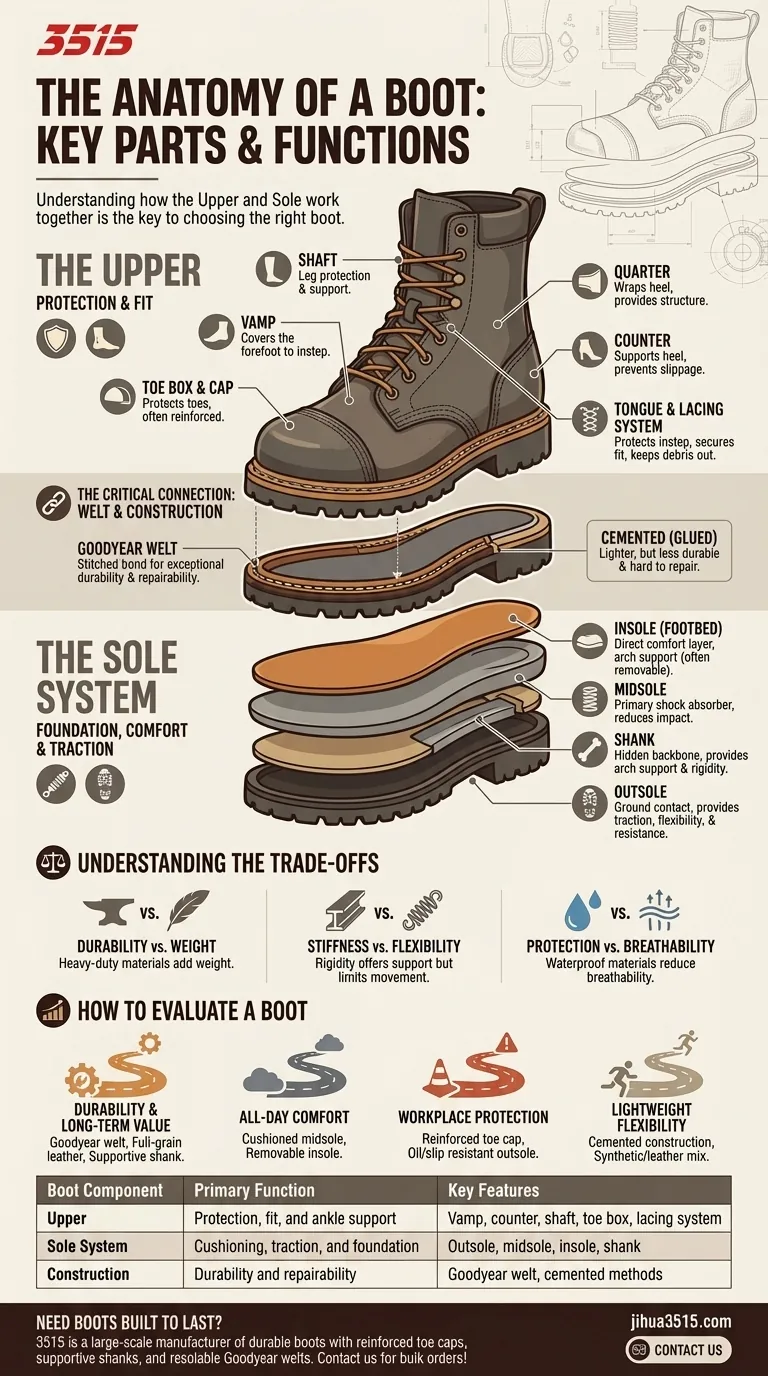

At its core, a boot is comprised of two main sections: the Upper, which covers your foot and ankle, and the Sole, which forms the foundation beneath it. Key components of the upper include the vamp, counter, and shaft, while the sole system is made up of the insole, midsole, and outsole. Understanding how these parts work together is the key to choosing the right boot for your needs.

A boot's anatomy is more than just a list of parts; it's a system where each component directly impacts the final product's support, durability, and comfort. By understanding the function of each piece, you can move beyond marketing and evaluate a boot based on its fundamental construction and quality.

The Anatomy of the Upper: Protection and Fit

The upper is everything above the sole. Its primary job is to protect your foot, provide a secure fit, and offer structural support around the ankle.

The Shaft, Vamp, and Quarter

The shaft is the part of the boot that extends up from the ankle, providing protection and support for the leg. The vamp covers the top of your foot, from the toe to the instep, while the quarter refers to the side and back panels that wrap around the heel.

The Toe Box and Counter

The toe box is the space at the front of the boot that covers and protects your toes. In work or safety boots, this is often reinforced with a toe cap made of steel or composite material. The counter is a stiff piece of material (often leather or thermoplastic) at the back of the boot that cups your heel, providing crucial support and preventing slippage.

The Tongue and Lacing System

The tongue is the strip of material that runs down the front of the boot under the laces. It protects your instep from pressure and helps keep debris out. The lacing system, which uses eyelets, hooks, or other garments, is essential for securing the boot and achieving a proper fit.

The Foundation: The Sole System

The sole is the entire structure underneath your foot. It is a layered system designed to provide cushioning, support, and traction.

The Outsole: Your Connection to the Ground

The outsole is the bottom-most layer that makes direct contact with the ground. Its material and tread pattern are critical for determining traction, flexibility, and resistance to wear, oil, or slipping.

The Midsole: The Shock Absorber

Sandwiched between the outsole and your foot, the midsole is the primary source of cushioning and shock absorption. Materials like EVA foam or polyurethane are commonly used here to reduce impact and provide comfort during long periods of wear.

The Insole (or Footbed): The Comfort Layer

The insole, also known as the footbed, is the layer directly inside the boot that your foot rests on. It provides the final layer of comfort and arch support. Many quality boots feature removable insoles, allowing you to insert custom orthotics.

The Shank: The Hidden Backbone

The shank is a stiff, supportive piece (often made of steel, fiberglass, or nylon) placed between the midsole and outsole. It runs under the arch of your foot, providing rigidity, protecting your arch from puncture, and reducing the load on your feet and calves.

The Critical Connection: Welt and Construction

How the upper is attached to the sole is one of the most significant indicators of a boot's quality and durability.

What is a Welt?

The welt is a strip of material, typically leather, that is stitched around the perimeter of the boot's upper. This welt is then stitched to the midsole and outsole, creating an incredibly strong and water-resistant bond.

Why Welt Construction Matters

This method, known as a Goodyear welt, makes a boot exceptionally durable and allows it to be resoled multiple times, dramatically extending its life. This stands in contrast to cheaper cemented (glued) constructions, which are lighter but cannot be easily repaired.

Understanding the Trade-offs

No single boot design is perfect for every situation. The construction involves inherent trade-offs between different performance characteristics.

Durability vs. Weight

Features that enhance durability, such as thick leather uppers, Goodyear welts, and dense rubber outsoles, also add significant weight. Lighter boots with synthetic materials and cemented soles are often more comfortable for casual wear but will not last as long under heavy use.

Stiffness vs. Flexibility

A rigid boot with a strong shank provides excellent support for carrying heavy loads or navigating uneven terrain. However, this same stiffness can feel restrictive and uncomfortable for simple walking on flat surfaces, where more flexibility is desired.

Protection vs. Breathability

Heavy-duty, waterproof materials offer maximum protection from the elements and workplace hazards. The downside is a lack of breathability, which can lead to discomfort and sweat buildup in warmer conditions.

How to Evaluate a Boot Based on Its Parts

Use your understanding of a boot's anatomy to choose the right features for your specific goal.

- If your primary focus is durability and long-term value: Look for a Goodyear welt construction, a full-grain leather upper, and a supportive shank.

- If your primary focus is all-day comfort for walking: Prioritize a well-cushioned midsole and a comfortable, removable insole that matches your arch.

- If your primary focus is protection in a work environment: Focus on a reinforced toe cap (steel or composite) and an outsole rated for oil and slip resistance.

- If your primary focus is lightweight flexibility for casual use: A boot with a cemented construction and a combination of leather and synthetic materials in the upper will be a suitable choice.

By looking beyond the surface and understanding the function of each component, you can confidently select a boot that is perfectly suited to its purpose.

Summary Table:

| Boot Component | Primary Function | Key Features |

|---|---|---|

| Upper | Protection, fit, and ankle support | Vamp, counter, shaft, toe box, lacing system |

| Sole System | Cushioning, traction, and foundation | Outsole, midsole, insole, shank |

| Construction | Durability and repairability | Goodyear welt, cemented methods |

Need boots built to last? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable boots with features like reinforced toe caps, supportive shanks, and resolable Goodyear welts—ensuring your customers get the quality they demand. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors