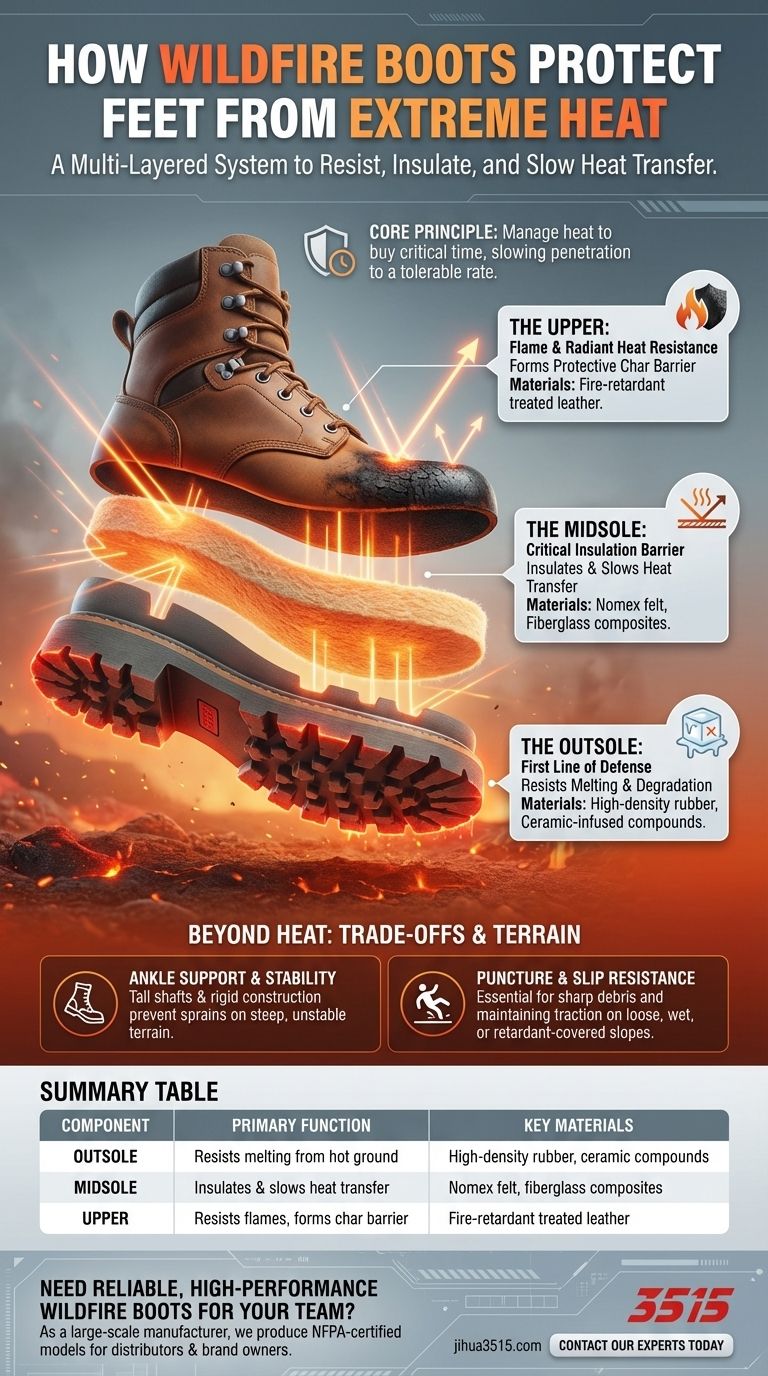

The short answer is that wildfire boots protect feet from extreme heat through a multi-layered system designed to resist, insulate, and slow down heat transfer. This is achieved using specialized heat-resistant outsoles, thick insulating midsoles made of materials like Nomex, and fire-retardant leather uppers that form a protective char barrier when exposed to flame.

The core principle isn't just to block heat, but to manage it. Wildfire boots are engineered as a complete thermal system that buys a firefighter critical time to move away from intense heat sources by slowing heat penetration to a tolerable rate.

The Anatomy of Heat Protection: A Layer-by-Layer System

To understand how these boots work, you must look at them not as a single piece of leather, but as three distinct defensive layers working in concert. Each component has a specific job in managing the extreme thermal load experienced on a fire line.

The Outsole: Your First Line of Defense

The outsole is the part of the boot that makes direct contact with the hot ground. Its primary job is to resist melting and degradation.

These are typically made from a specialized, high-density rubber or even ceramic-infused compounds. Unlike standard boot soles that would soften or melt, these materials are designed to maintain their structural integrity at very high temperatures.

The Midsole: The Critical Insulation Barrier

The midsole is the most important layer for preventing heat from reaching your foot. Its function is pure insulation.

This layer is often made from heat-blocking materials like Nomex felt or fiberglass composites. These materials are poor conductors of heat, meaning they significantly slow down the rate at which thermal energy can travel from the hot outsole to the interior of the boot.

The Upper Materials: Resisting Flames and Radiant Heat

The upper part of the boot is typically made of thick, durable leather treated with fire-retardant chemicals.

When exposed to direct flame, this treatment causes the leather to form a char barrier. This blackened, carbonized layer is itself an excellent insulator and helps prevent the rest of the material from igniting, shielding the firefighter from both radiant heat and direct flame contact.

Understanding the Trade-offs and Terrain

A boot designed solely for heat resistance would fail in the field. Wildfire boots are engineered for a hostile and unpredictable environment, requiring a balance of features that go beyond just managing temperature.

Ankle Support and Stability

Wildland firefighters operate on steep, unstable, and often obscured terrain. The tall shafts and rigid construction of these boots are critical for preventing sprains and providing stability, which is just as important to safety as heat resistance.

Puncture and Slip Resistance

The fire line is littered with sharp debris, from broken branches to unseen hazards under ash. Puncture-resistant soles are non-negotiable.

Furthermore, aggressive, slip-resistant treads are essential for maintaining traction on loose soil, wet surfaces, or slopes covered in fire retardant. A slip at the wrong moment can be catastrophic.

The Difference From Other Protective Boots

While structural firefighting boots or standard work boots offer protection, they are designed for different hazards. Structural boots handle intense heat but also immersion in water and impacts from falling debris. A standard work boot may have an optional heat rating, but it lacks the comprehensive insulating system and rugged design needed for hours or days on a wildfire.

Making the Right Choice for Your Understanding

Your understanding of this equipment depends on your specific goal.

- If your primary focus is heat resistance: Know that it comes from the synergy between the melt-resistant outsole, the insulating midsole, and the charring effect of the treated uppers.

- If your primary focus is overall firefighter safety: Recognize that heat protection is just one critical component in a system that must also provide extreme durability, ankle stability, and traction for treacherous terrain.

Ultimately, every feature of a wildfire boot is a piece of an engineered solution designed to protect a life in an environment where every step matters.

Summary Table:

| Boot Component | Primary Function | Key Materials |

|---|---|---|

| Outsole | Resists melting from hot ground contact | High-density rubber, ceramic compounds |

| Midsole | Insulates and slows heat transfer | Nomex felt, fiberglass composites |

| Upper | Resists flames and forms a protective char barrier | Fire-retardant treated leather |

Need reliable, high-performance wildfire boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of professional boots, including NFPA-certified models built with the multi-layer heat protection system described above.

We ensure your personnel are equipped with durable, safe, and compliant footwear designed for the most demanding environments.

Contact our experts today to discuss your specific requirements and request a quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Grain Leather Safety Boots for Bulk Supply

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

People Also Ask

- How long can heavily worn but well-maintained Goodyear-welted shoes last? 5-10+ Years with Proper Care

- How should heavy duty work boots be maintained? Maximize Lifespan and Safety

- How have modern Wellington work boots evolved? From Basic Rain Boots to High-Tech Safety Gear

- What are the key steps to ensure work boots last longer from the start? Maximize Durability & Lifespan

- What are the main characteristics of PU as a material for work boots? Lightweight, Flexible & Durable

- Why are PVC work boots considered waterproof? The Science of Absolute Water Protection

- How does routine boot maintenance benefit workplace safety? Proactive PPE Protection for Your Workforce

- What are the essential features all work boots should have regardless of gender? Non-Negotiable Safety & Support