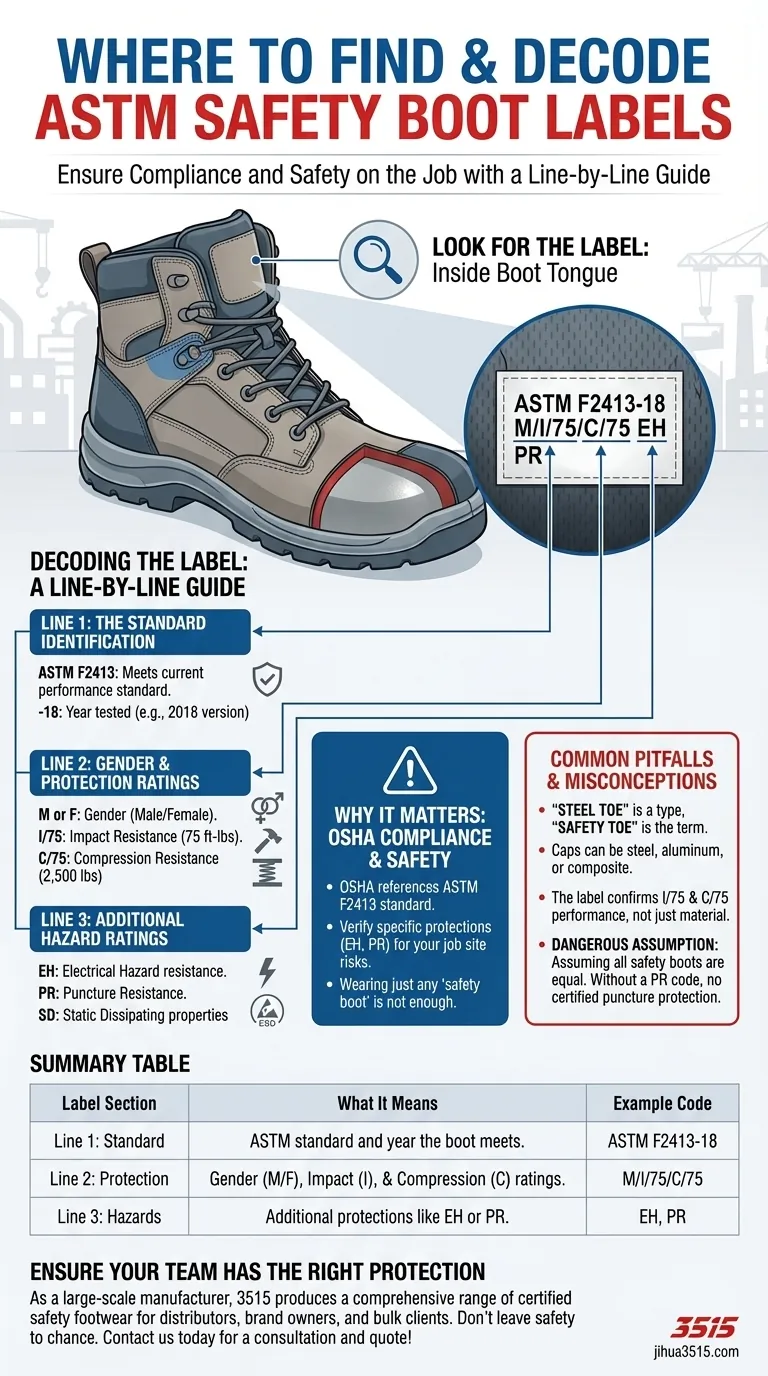

To find the ASTM code, look for a sewn-in label on the inside of the boot's tongue. This label contains critical safety information, with the first line identifying the ASTM standard and subsequent lines detailing the specific types of protection the boot provides.

The location of the safety label is simple, but its true value lies in understanding the codes printed on it. This information is your definitive guide to ensuring the boot you are wearing provides the exact protection required for your specific work environment.

Decoding the ASTM Label: A Line-by-Line Guide

The ASTM label is a standardized system that details the performance and safety features of your footwear. It typically consists of two to three lines of alphanumeric codes.

Line 1: The Standard Identification

The first line identifies that the boot complies with the current ASTM International performance standard.

It will read ASTM F2413, followed by the year of the standard it was tested against (e.g., -18 for the 2018 version). This confirms the footwear meets the requirements for safety toe protective footwear.

Line 2: Gender and Protection Ratings

The second line is the most critical for day-to-day use, as it specifies the type and level of protection.

It begins with the gender the boot was designed for (M for male, F for female). This is followed by the ratings for impact resistance (I) and compression resistance (C). The number 75 is the highest rating, indicating protection against 75 ft-lbs of impact and 2,500 lbs of compression.

A typical high-performance boot label would show: M/I/75/C/75.

Line 3: Additional Hazard Ratings

A third line may be present to denote protection against additional, specific workplace hazards.

Common codes include EH for Electrical Hazard resistance, PR for Puncture Resistance, and SD for Static Dissipating properties. These codes are only present if the boot is certified for that specific protection.

Why This Label Matters: Compliance and Safety

Understanding the ASTM label is not just an academic exercise; it is fundamental to workplace safety and regulatory compliance.

The Role of OSHA

The Occupational Safety and Health Administration (OSHA) requires employers to ensure employees use protective footwear in hazardous environments.

While OSHA sets the requirement, it references the ASTM F2413 standard as the benchmark for what constitutes adequate protection. This makes the ASTM label the primary method for verifying compliance.

The Importance of Verification

Simply wearing a "steel toe" boot is not enough. A job site may require specific protections, such as resistance to electrical shocks (EH) or sole punctures (PR).

Checking the label is the only reliable way to confirm your boot provides the certified protection needed to keep you safe from the specific risks of your job.

Common Pitfalls and Misconceptions

Navigating safety footwear can be confusing. Being aware of common mistakes ensures you are genuinely protected.

"Steel Toe" vs. "Safety Toe"

"Safety toe" is the correct, broad term. The protective toe cap can be made of steel, aluminum alloy, or composite materials.

All are capable of meeting the ASTM I/75 and C/75 standards. The label confirms the performance, regardless of the material used.

Assuming All Safety Boots are Equal

The most dangerous assumption is that any safety boot will suffice for any hazardous job.

A boot without a PR rating offers no certified protection against stepping on a nail. A boot without an EH rating must not be used by electricians or others working near live circuits. The specific codes are critical.

Verifying the Right Protection for Your Task

Use the ASTM label as a tool to make an informed decision about your personal protective equipment.

- If your primary focus is job site compliance: Match the codes on your boot's tongue label directly against the specific requirements listed in your site's safety plan.

- If your primary focus is purchasing new boots: First, identify the unique hazards of your work (e.g., falling objects, electrical risk, sharp debris) and then find a boot with the corresponding ASTM codes.

- If your primary focus is evaluating old boots: Check that the label is still legible and that the boot is in good structural condition, as physical damage can compromise its protective capabilities.

Ultimately, understanding this label empowers you to take direct control of your own safety on the job.

Summary Table:

| Label Section | What It Means | Example Code |

|---|---|---|

| Line 1: Standard | The ASTM standard and year the boot meets. | ASTM F2413-18 |

| Line 2: Protection | Gender (M/F), Impact (I), and Compression (C) ratings. | M/I/75/C/75 |

| Line 3: Hazards | Additional protections like Electrical Hazard (EH) or Puncture Resistance (PR). | EH, PR |

Ensure Your Team Has the Right Protection

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, ensuring they meet the exact ASTM standards your workforce requires.

Don't leave safety to chance. Let us provide your team with durable, compliant footwear tailored to your specific hazards.

Contact us today for a consultation and quote!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why is it important to wear steel toe work boots? Maximum Impact Protection for Hazardous Work

- What additional safety features do steel toe work boots often include? Beyond the Steel Toe Cap

- How do women's safety toe work boots protect against foot injuries? A Complete Guide to Workplace Foot Safety

- What is the overall recommendation regarding steel toe boot usage? Essential for Maximum Protection

- Do steel toe boots increase the risk of trips and falls? How Quality Design Enhances Stability